Tight schedules in bridge and tower fabrication are colliding with labor shortages, long plate lead times, and limited bay space, and the result is a familiar failure mode: parts hit the floor late or inconsistent, crews work around missing features, and rework steals shifts when delivery windows are non-negotiable. As Regional Sales Executive at Mac-Tech, I act as the single point of contact to coordinate procurement-to-production governance and turnkey automation so owners and GMs can protect throughput, control spec, and tie investment to measurable ROI.

Procurement to Production Governance Gaps Driving Late Spec Delivery

When procurement, engineering, and production each optimize locally, spec drift becomes expensive: purchasing substitutes material to meet dates, engineering releases partial revisions, and the shop runs what is available rather than what is correct. The business impact is predictable: missed ship dates, premium freight, and rework that consumes planned capacity and erodes margin.

Common governance gaps that show up on the floor

- Engineering revisions not tied to purchase order line items, creating 2–4 manual touchpoints per change and a 24–72 hour lag before the shop sees the right spec

- Material substitutions approved by email without a controlled disposition, driving 3–8% rework on welded assemblies and fit-up delays of 2–6 hours per job

- Nesting, cut, drill, and fit processes executed on different “versions of truth,” adding 1–2 shifts of queue time waiting for clarification

- Incomplete receiving validation, causing wrong grade or heat traceability issues discovered after cutting, resulting in scrap events measured in full plates or beams

RYTECH CORE+ PRECISION HYDRAULIC PRESS BRAKE

Precision. Performance. Innovation.

The RYTECH CORE+ delivers elite bending performance with modular automation compatibility, premium hybrid servo systems, and advanced control — backed by…

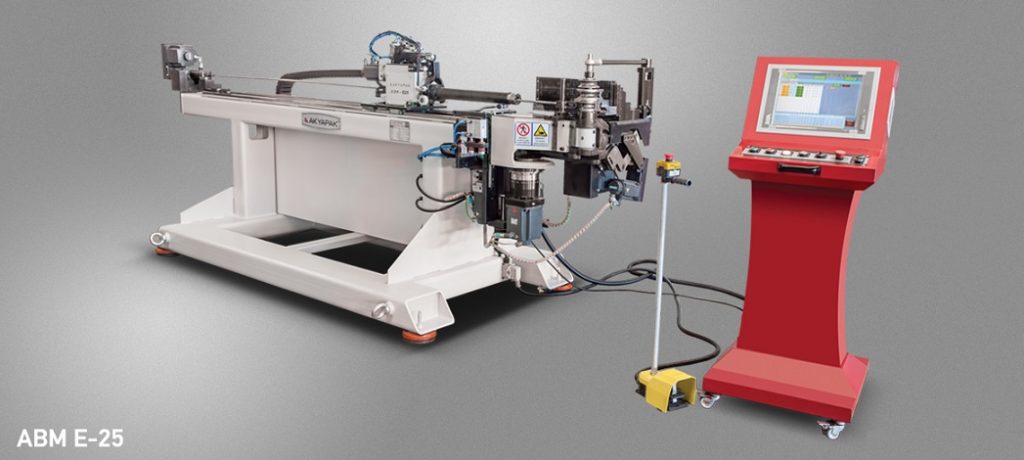

ABM E-25

Decision Criteria for Spec Control Across Purchasing, Engineering, and Shop Execution

Executives need a decision framework that assigns authority, timing, and evidence for every spec-affecting decision, especially on complex equipment programs. In structural fabrication, the fastest path is not always the safest path; the goal is controlled speed with documented approvals that keep production moving.

Decision criteria that prevent late spec delivery

- Revision authority and timing: no shop release without a controlled CAD or drawing revision ID and an approved effective date (same-shift visibility)

- Material equivalency rules: pre-approved alternates by grade, thickness, and forming limits, with documented deviation disposition within 4 business hours

- Routing impact check: every spec change triggers a routing and tooling impact review for cut, drill, bevel, form, and weld steps in under 30 minutes

- Proof of compliance: heat cert capture at receiving and linkage to work order, targeting 100% traceability on critical members and 98% overall

Where equipment choice affects governance

- Prodevco beam drilling and processing lines reduce manual layout dependency and help lock feature accuracy to the approved model, lowering downstream fit-up correction

- HSG Fiber Lasers and matched automation reduce part variability and handling touches, supporting consistent cut quality and shorter queue time before weld

- Akyapak, Ermaksan, Ercolina, and Liberty solutions can be selected where bending, forming, or plate processing constraints are the true bottleneck, but only if the spec control rules are enforced upstream

Integrated Governance Model with Dave Graf as Single Point of Contact for Automation and Integration

Governance works when it is owned, not “shared by everyone,” and when the operating system connects purchasing signals to engineering intent and shop execution. My role is to coordinate a single, integrated plan across equipment selection, layout, software handshakes, and service continuity so accountability is clear and performance is measurable.

What I coordinate end-to-end

- Front-end alignment: cross-functional workshop with engineering, ops, finance, and procurement to define spec gates and approval SLAs (typically 2–3 hours, 1 session)

- System integration scope: ERP to MES to CAD release mapping, with a controlled revision ID flowing to nesting, CNC, and traveler outputs (targeting zero manual re-key)

- Layout and material flow: cell design to reduce handling touches by 20–40% and cut internal transport time by 30–60 minutes per shift

- Installation, commissioning, training: planned cutover to protect uptime, with operator and maintenance training tied to standard work and documented change control

For teams evaluating machines or tooling, I also point stakeholders to standardized options and consumables through https://shop.mac-tech.com/ so procurement can align ordering to the same spec governance used on the floor.

Implementation Risks in ERP MES CAD Data Handshakes and Change Management Controls

Most schedule slips happen in the handoffs: a drawing revision that does not match the CNC program, a work order that does not reflect a material substitution, or an MES status that does not trigger procurement actions. The risk is not technology alone; it is weak change management that leaves operators and buyers guessing.

High-probability risks to control early

- Revision mismatch risk: CAD model rev differs from CNC program rev, creating 1–3 hours of investigation per incident and unplanned machine downtime

- Master data drift: part numbers, grades, and thickness tables differ across systems, driving incorrect nests or tooling selection 1–2 times per week in high-mix environments

- Uncontrolled substitutions: procurement expedites with alternates that violate forming or weld procedure limits, resulting in weld repairs and NDT failures

- Cutover disruption: commissioning without a phased run-in plan can cost 1–2 production shifts; mitigation is staged acceptance testing and parallel run criteria

Controls that reduce disruption

- Change orders require a single digital disposition record linked to PO, job, and CNC output, with shop-floor visibility within the same shift

- A defined rollback plan for ERP or MES handshake changes, with a 30-minute recovery target for critical production cells

KPIs and Audit Cadence to Measure On-Time Spec Delivery and Rework Reduction

Executives need leading indicators that predict late delivery before it hits the dock, not lagging metrics that explain problems after margin is gone. The KPI set should tie directly to spec control, queue time, and capacity protection, with a cadence that drives action.

Core KPIs for governance and throughput

- On-time spec release rate: percent of work orders released with correct revision and complete BOM, target 98%+ weekly

- First-pass yield at fit-up: target 95–98%, measured by weld prep and hole alignment rework hours per job (goal: <1.0 hour per 10 tons)

- Rework rate: percent of labor hours coded to rework, target reduction from 6–10% down to 2–4% within 90–180 days

- Queue time between cut, drill, and weld: target reduction of 20–35%, measured in hours per batch or days per work order

- Equipment utilization with spec compliance: utilization tracked with “good parts only,” target 65–80% depending on mix and shifts

Audit cadence that keeps accountability real

- Daily 10-minute exception review for spec deviations and material shortages

- Weekly cross-functional governance audit of top 10 change events and their cycle time to disposition

- Monthly executive review tying delivery performance to cost of rework, premium freight, and capacity utilization

Next Steps for Structural Fabricators to Standardize Procurement to Production Integration

Start with a fast diagnostic that maps every spec touchpoint from quote assumptions to receiving, CAD release, nesting, CNC execution, and inspection. From there, standardize the governance gates and then select automation that supports the process, not the other way around, whether that is a Prodevco processing line, an HSG Fiber Laser cell, or complementary solutions from Akyapak, Liberty, Ermaksan, or Ercolina based on your constraint.

Practical 30–60 day actions

- Run a value-stream map focused on spec changes, capturing: number of approvals, average disposition time, and rework hours per change event

- Define a single revision and substitution policy with measurable SLAs: 4-hour disposition, same-shift shop notification, 100% PO linkage

- Pilot one integrated cell with controlled handshakes and acceptance tests, targeting: 10–20% throughput gain and 25–50% reduction in avoidable rework hours

- Use standardized purchasing paths for tooling, parts, and consumables to reduce lead time variability via https://shop.mac-tech.com/

FAQ

What lead times should I plan for equipment plus integration?

Most projects require a phased plan that includes equipment lead time, site readiness, and commissioning; I coordinate milestones so production disruption is minimized.

How do we reduce implementation risk in ERP, MES, and CAD handshakes?

We define a single revision ID, test data mappings in a staged environment, and use acceptance criteria that prove the shop is running the correct spec before cutover.

What training is required for operators and maintenance teams?

Training should be role-based with standard work, typically including operator setup and troubleshooting plus maintenance PM routines aligned to your shift schedule.

How do we protect uptime during installation and commissioning?

We plan around production peaks, stage utilities and material flow, and execute a run-in plan that limits unplanned downtime to agreed thresholds.

How is ROI measured beyond cycle time?

I recommend tracking on-time spec release, first-pass yield, rework labor, queue time, and premium freight so finance can see margin protection, not just speed.

Can Mac-Tech coordinate multi-system projects as one scope?

Yes, I serve as the one-call coordinator across layout, integration scope, installation, training, and long-term service continuity so ownership stays clear.

Contact me for planning, demonstrations, or full project coordination: dave@mac-tech.com | 602-510-5552 | https://shop.mac-tech.com/

Get Weekly Mac-Tech News & Updates