Precision Tube Bending for Oil & Gas: Ercolina’s Tight-Radius Reliability

In the ever-evolving landscape of oil & gas, shipbuilding, and infrastructure, fabricators face common operational challenges: labor shortages, throughput limitations, and unexpected downtimes. As a trusted advisor at Mac-Tech, I, Dave Graf, am committed to providing turnkey automation and ROI-focused solutions tailored to these industries. Let’s explore how precision tube bending can streamline operations and boost efficiency.

The Role of Precision Tube Bending in Oil & Gas

The oil & gas sector demands precision and reliability, especially when dealing with pipeline and refinery components. Fabricators often struggle with maintaining tight-radius accuracy, crucial for the intricate bends required in these applications. Even minor deviations can lead to significant inefficiencies and increased costs.

At Mac-Tech, we leverage Ercolina’s technology to deliver consistent and precise tube bending solutions. Ercolina machines are engineered to handle complex bends with unparalleled accuracy and repeatability, ensuring that each component meets the rigorous standards set by the industry.

Achieving Tight-Radius Reliability with Ercolina

Ercolina’s advanced machinery is designed to tackle the challenge of tight-radius bending head-on. The precision control system ensures that every bend adheres to exact specifications, reducing the risk of rework and scrap.

The benefits are clear: faster throughput and improved uptime mean projects stay on schedule and within budget. As your single point of contact, I coordinate the integration, installation, and service of these systems to ensure seamless operation from day one.

GREEN FX SERVO

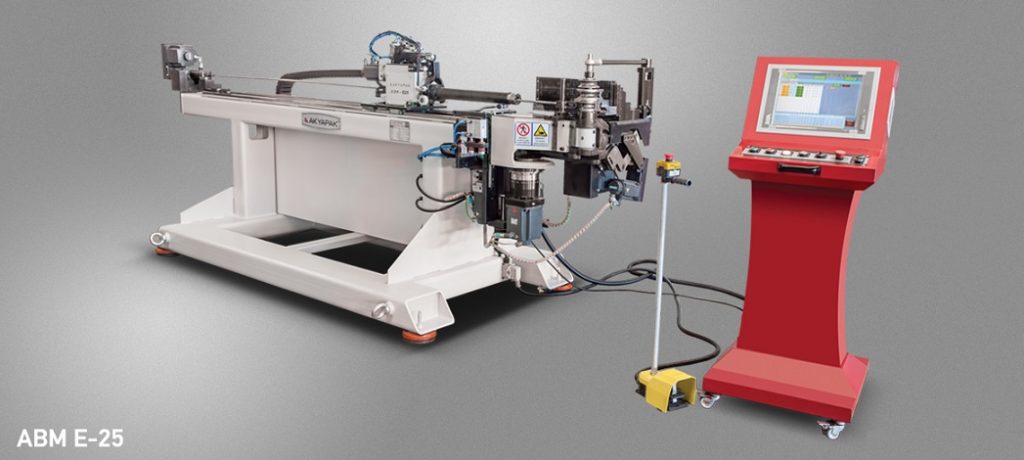

ABM E-25

Maximizing ROI through Automation in Fabrication

Automation is key to maximizing ROI in fabrication. By integrating Ercolina machines with other automated systems like Prodevco and Liberty, we create a streamlined production line that minimizes manual intervention and maximizes efficiency.

This approach not only cuts labor costs but also enhances overall productivity. I work closely with your team to ensure that each piece of equipment is optimized for your specific operational needs, delivering a solution that’s as unique as your business.

Streamlining Processes: From Oilfields to Shipyards

Ercolina’s precision tube bending capabilities extend beyond oil & gas, offering significant advantages in shipbuilding and infrastructure projects. The ability to produce consistent, high-quality bends quickly translates into reduced lead times and enhanced project delivery.

At Mac-Tech, we ensure that the transition from oilfields to shipyards is smooth, coordinating every aspect of the process to eliminate bottlenecks and boost efficiency across the board.

Single-Contact Efficiency: Simplifying System Integration

Integrating new technology can be daunting, but with Mac-Tech, it doesn’t have to be. I serve as your single point of contact, simplifying the complexity of system integration. Whether it’s combining lasers, rolls, or beam systems, I ensure a seamless process that aligns with your operational goals.

Our comprehensive support covers every stage, from planning and installation to ongoing maintenance and upgrades, guaranteeing long-term success.

Cutting Labor Costs with Advanced Structural Automation

The adoption of advanced structural automation significantly reduces labor costs, a crucial factor in maintaining competitiveness. Ercolina’s machines, combined with our expertise in automation, allow for a reduction in manual labor without compromising quality or output.

By investing in this technology, you not only cut costs but also position your company as a leader in innovation and efficiency.

FAQ Section

What are the lead times for integrating new systems?

Lead times vary depending on the complexity of the system. However, our streamlined process ensures a quick turnaround, with installation and training included in our service.

How is performance measured after integration?

We provide comprehensive metrics and analysis tools to measure performance improvements post-integration, ensuring you see tangible ROI.

What kind of maintenance and training is provided?

Comprehensive training is offered during installation, with ongoing maintenance support to keep your systems running optimally.

Can Ercolina machines be integrated with existing equipment?

Yes, Ercolina machines are designed for compatibility and can be seamlessly integrated with your current setup.

What lifecycle support and upgrade options are available?

We offer full lifecycle support, from installation to upgrades, ensuring your equipment remains cutting-edge.

For system planning, demonstrations, or complete project coordination, feel free to contact me directly. Let’s work together to enhance your operations and achieve new levels of productivity.

Dave Graf

Regional Sales Executive, Mac-Tech

dave@mac-tech.com

Get Weekly Mac-Tech News & Updates