As a Regional Sales Executive at Mac-Tech, I’ve spent years helping Indiana fabricators navigate the complexities of equipment investment. My role is not just about selling machines; it’s about understanding the unique challenges each client faces and providing solutions that enhance their operations. By leveraging my expertise in laser technology, I aim to guide fabricators toward smarter, more profitable decisions.

Understanding Section 179: A Game-Changer for Indiana Fabricators

Section 179 of the IRS tax code offers a significant opportunity for Indiana fabricators looking to upgrade their equipment. This provision allows businesses to deduct the full purchase price of qualifying equipment, including lasers, from their gross income. By making strategic investments before the end of 2025, fabricators can write off those purchases and reduce their tax burden, positioning themselves for a more profitable future.

The benefits of Section 179 extend beyond immediate tax relief. For fabricators, this means the ability to invest in advanced technology without the financial strain typically associated with large capital expenditures. By upgrading to more efficient and precise laser systems, businesses can enhance their production capabilities and stay competitive in a rapidly evolving market.

Leveraging Personal Expertise: Building Strong Client Relationships

In my experience, building strong relationships with clients is crucial to understanding their specific needs and challenges. Each fabricator I work with has unique production goals, and it’s my job to tailor solutions that meet those objectives. By offering one-on-one consultations, I can provide personalized advice that aligns with their core work and long-term vision.

This approach not only fosters trust but also ensures that clients are investing in equipment that truly adds value to their operations. Whether it’s selecting the right laser system or enhancing existing setups with new tooling, my goal is to empower fabricators with the knowledge and resources they need to succeed.

LIBERTY SYSTEMS BURR REDUCTION SYSTEM GAS MIXER

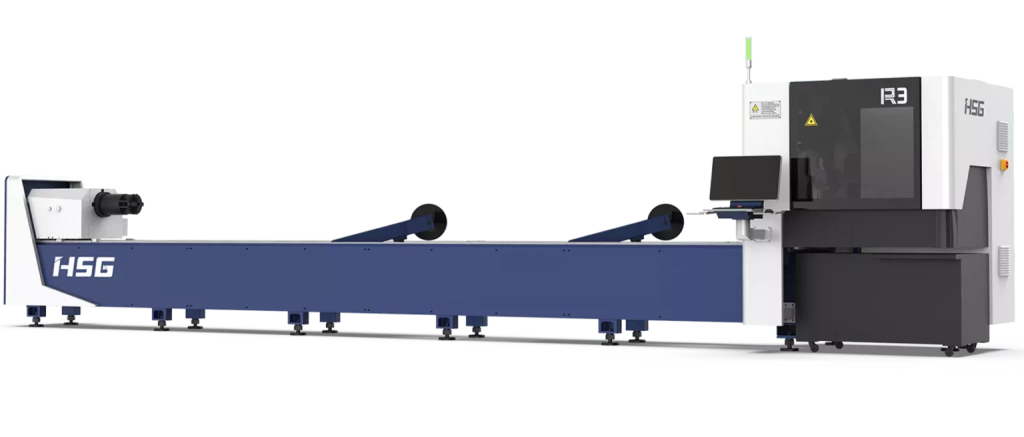

R3 PLUS-TUBE FIBER LASER CUTTING MACHINE

- Standard container transport

- Automatic loading and unloading

- HSG-X Bus control

Addressing Fabrication Challenges: Efficiency and Performance Goals

Indiana fabricators face numerous challenges, from increasing production demands to maintaining high-quality standards. Efficiency and performance are at the forefront of these concerns. To address them, it’s essential to invest in equipment that offers both precision and power. The choice between sheet and plate lasers, for instance, should be guided by the specific materials and thicknesses involved in the core work.

By focusing on beam quality and power, fabricators can optimize their processes, reduce waste, and improve overall production speed. A well-chosen laser system not only meets current demands but also provides the flexibility to adapt to future challenges, ensuring long-term success.

Maximizing Laser System Investments: Insights and Innovations

Investing in the latest laser technology can significantly enhance a fabricator’s capabilities. Innovations in laser systems, such as improved beam quality and increased power efficiency, allow for more precise cuts and faster processing times. These advancements lead to better product quality and reduced operational costs.

At Mac-Tech, we’re committed to helping clients maximize their investments by providing access to cutting-edge technology and comprehensive support. From installation to ongoing maintenance, our team ensures that each laser system operates at peak performance, allowing fabricators to focus on what they do best—producing high-quality products efficiently.

Making Informed Decisions: ROI-Focused Equipment Strategies

When selecting new equipment, understanding the return on investment is crucial. Fabricators must consider not only the initial cost but also the long-term benefits of increased efficiency and reduced downtime. By focusing on ROI, businesses can make informed decisions that align with their financial goals and production needs.

Choosing the right laser system involves evaluating factors such as beam quality, power, and compatibility with existing processes. By prioritizing these elements, fabricators can ensure that their investments lead to tangible improvements in productivity and profitability.

FAQ

What is Section 179, and how does it benefit fabricators?

Section 179 allows businesses to deduct the full purchase price of qualifying equipment, reducing taxable income and providing immediate financial benefits.

How do I choose between sheet and plate lasers?

Consider the materials and thicknesses you work with most frequently. Beam quality and power are critical factors in this decision.

What are the main advantages of modern laser systems?

Modern lasers offer enhanced precision, faster processing times, and improved energy efficiency, contributing to better product quality and reduced costs.

How can I ensure my laser system remains efficient?

Regular maintenance and updates are essential. Partnering with a reliable provider ensures your system operates at its best.

Is it worth upgrading my current equipment?

If your existing setup doesn’t meet your efficiency and quality goals, investing in newer technology could lead to significant long-term savings.

Get Weekly Mac-Tech News & Updates