Revolutionizing Structural Fabrication with Liberty Press Brakes

In today’s fast-paced structural steel fabrication industry, companies in oil & gas, shipbuilding, and infrastructure sectors face significant challenges such as labor shortages, throughput limitations, and costly downtime. These issues demand innovative solutions to maintain competitive edges and meet growing demands. As a Regional Sales Executive at Mac-Tech, I am your trusted advisor and single point of contact, offering turnkey automation solutions that focus on maximizing ROI and efficiency.

Maximizing ROI Through Automation in Fabrication Industries

The structural fabrication industry is under constant pressure to deliver high-quality products swiftly and cost-effectively. Labor shortages exacerbate this challenge, making automated solutions crucial. Liberty Press Brakes offer a transformative approach by integrating seamlessly into automated production lines, reducing manual handling, and improving output. By investing in automation, companies can achieve faster throughput, less rework, and improved uptime, ultimately enhancing their return on investment.

Streamlining Production: Labor Savings with Press Brake Automation

Labor shortages and high operational costs are persistent obstacles. Liberty Press Brakes, with their advanced technology, reduce dependency on manual labor, streamlining operations significantly. Automated systems ensure precision and consistency, minimizing errors and rework. This efficiency not only saves time but also reduces costs associated with labor and material waste. By adopting these systems, fabricators can focus on strategic growth rather than operational bottlenecks.

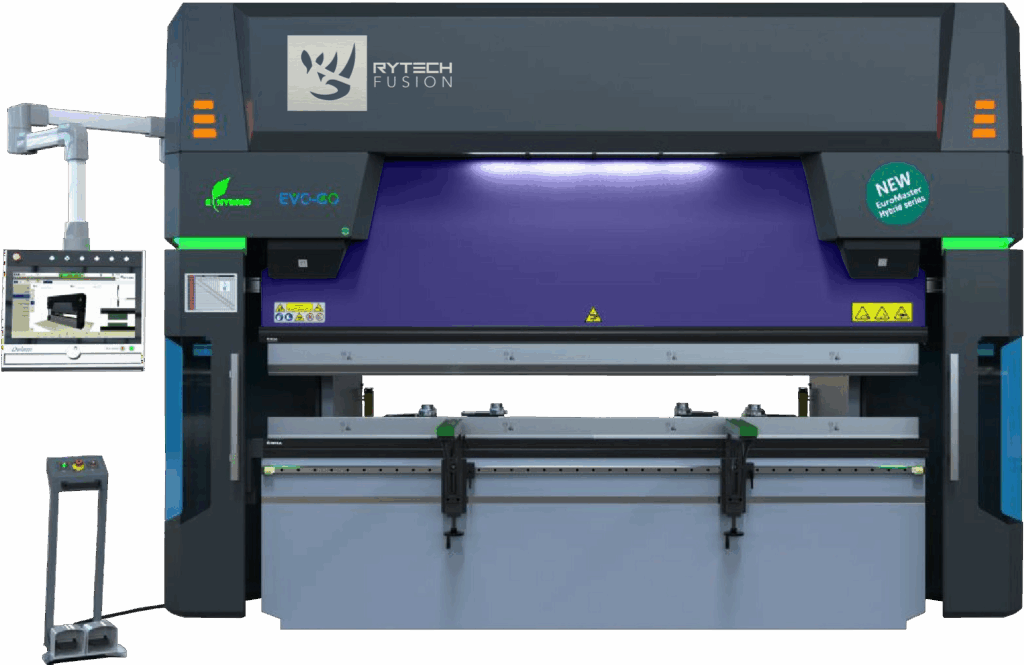

RYTECH FUSION HYBRID PERFORMANCE PRESS BRAKE

RyTech Press Brakes: Engineered for Power, Precision, and Performance

RyTech press brakes deliver exceptional bending performance across a broad spectrum of applications. With a comprehensive…

RYTECH FORCE-1 HE 2204

System Integration: A Single Contact for Structural Automation

Integrating complex systems like Liberty Press Brakes into existing production lines can be daunting. At Mac-Tech, I coordinate every aspect of integration, installation, and ongoing support. From initial consultation to system calibration and service, I ensure a seamless experience. Our holistic approach allows clients to have a single point of contact for all their automation needs, simplifying processes and reducing the stress of managing multiple vendors.

Ensuring Reliability in Oilfield, Bridge, Shipyard, and Tower Fabrication

Reliability is paramount in industries like oilfield, bridge, shipyard, and tower fabrication. Downtime can lead to significant financial losses and project delays. Liberty Press Brakes are engineered for durability and precision, ensuring consistent performance even in demanding environments. By implementing these robust solutions, companies can enhance their operational reliability, ensuring projects are completed on time and within budget.

FAQ Section

What are the lead times for integrating Liberty Press Brakes?

Lead times vary based on project complexity, but we strive to deliver and integrate systems efficiently to minimize downtime.

How is maintenance handled post-installation?

Our team offers comprehensive maintenance plans, ensuring your systems operate at peak efficiency with minimal interruptions.

What training is provided for staff?

We provide detailed training sessions for your team to ensure they are proficient in operating and maintaining the systems.

How do we measure ROI and performance?

We work closely with you to establish key performance indicators and provide tools to monitor system efficiency and returns.

Can Liberty Press Brakes integrate with existing laser, roll, and beam systems?

Yes, Liberty Press Brakes are designed for seamless integration with a variety of existing systems, enhancing overall production efficiency.

What lifecycle support and upgrade options are available?

We offer ongoing support and periodic upgrades to ensure your systems remain state-of-the-art and meet evolving industry standards.

As your one-call partner, I am dedicated to delivering complex solutions seamlessly, ensuring your operations are optimized and future-ready.

I invite executives to contact me at dave@mac-tech.com for system planning, demonstrations, or complete project coordination. Let’s revolutionize your production efficiency together.

Get Weekly Mac-Tech News & Updates