Mac-Tech has long been a leader in providing top-tier fabrication equipment, known for its commitment to quality and innovation. The introduction of HSG tube lasers into their portfolio further underscores this reputation. These machines are an essential addition to any modern fabrication shop, offering a strategic solution to streamline operations and enhance productivity. With the ability to consolidate multiple processes into a single system, HSG tube lasers are revolutionizing the way fabricators approach their workflows.

Boost Productivity with Advanced Tube Laser Technology

Iowa fabricators are increasingly recognizing the value of HSG tube lasers as a means to boost productivity. These state-of-the-art machines are designed to handle complex cutting tasks with ease, replacing older, labor-intensive methods such as sawing and coping. By automating these processes, fabricators can significantly reduce manual labor, allowing skilled workers to focus on more critical tasks. This shift not only enhances operational efficiency but also reduces the likelihood of errors, leading to higher-quality outputs.

The versatility of HSG tube lasers makes them ideal for a wide range of applications, from automotive to aerospace. Their ability to cut various materials with precision ensures that fabricators can meet diverse client demands without compromising on quality. As a result, shops can take on more projects, increasing throughput and driving business growth.

Precision and Efficiency: The Hallmarks of HSG Tube Lasers

HSG tube lasers are renowned for their precision and efficiency. Equipped with advanced technology, these machines offer unparalleled accuracy, ensuring clean cuts and minimal material waste. This precision is crucial in industries where even the smallest deviation can lead to significant issues, making HSG tube lasers a reliable choice for high-stakes projects.

Efficiency is further enhanced by the machine’s speed. HSG tube lasers can complete tasks in a fraction of the time required by traditional methods, allowing fabricators to meet tight deadlines without sacrificing quality. This combination of speed and accuracy makes them an invaluable asset for any shop looking to enhance its competitive edge.

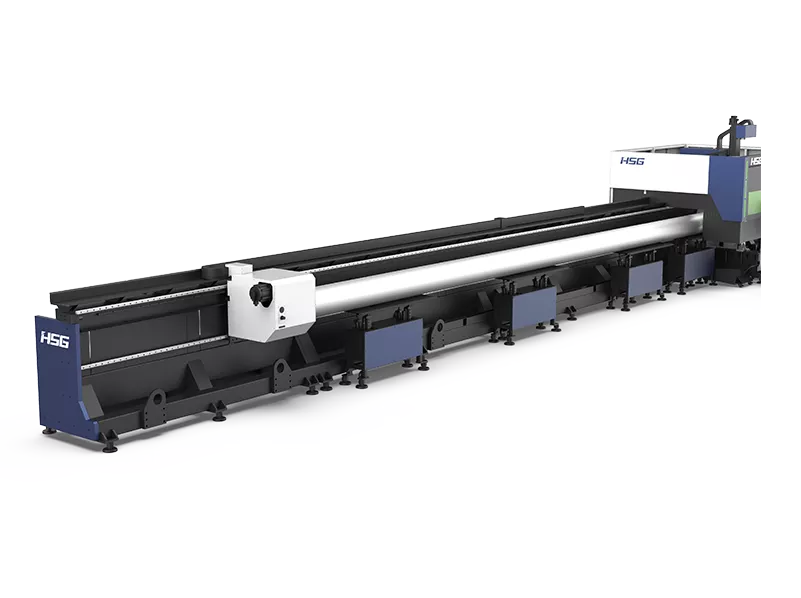

TX PLUS DOUBLE-CHUCK TUBE FIBER LASER CUTTING MACHINE

- Double chuck with upgraded processing ability

- Heavy-duty side lateral machine bed

- Whole track rectangular circle chucks

- HSG-X Bus control system

HSG TX3R PROFESSIONAL HEAVY-DUTY TUBE LASER CUTTING MACHINE

Redefining Large-Diameter Tube Processing

The HSG TX3R is built for fabricators who demand precision, speed, and efficiency when processing heavy-duty tubes and profiles. With intelligent self-centering chucks,…

Maximize ROI with Cost-Effective Automation Solutions

Investing in HSG tube lasers is a strategic move for fabricators aiming to maximize their return on investment. Thanks to Section 179 deductions, the financial burden of upgrading equipment is significantly reduced, making it feasible for shops to transition to this advanced technology. By consolidating multiple processes into a single system, fabricators can lower labor costs and improve overall efficiency.

The long-term savings associated with reduced labor and material waste, coupled with the tax advantages, ensure a quick return on investment. Furthermore, the durability and reliability of HSG tube lasers mean lower maintenance costs and less downtime, contributing to sustained profitability.

Enhance Fabrication Capabilities with Cutting-Edge Features

HSG tube lasers come equipped with cutting-edge features designed to enhance fabrication capabilities. These include automatic loading and unloading systems, which streamline operations and reduce the need for manual intervention. Such automation not only speeds up the production process but also minimizes the risk of human error.

Additionally, the machines offer user-friendly interfaces and customizable settings, allowing operators to tailor operations to specific project requirements. This flexibility ensures that fabricators can adapt quickly to changing client needs, maintaining a high level of service and satisfaction.

Seamless Integration for Streamlined Operations

One of the standout features of HSG tube lasers is their ability to seamlessly integrate into existing workflows. Mac-Tech ensures that the procurement and installation process is smooth, with expert teams available to assist with setup and training. This support guarantees that fabricators can quickly harness the full potential of their new equipment.

Post-sale support is another area where Mac-Tech excels, offering ongoing maintenance services and technical assistance. This commitment to customer service ensures that operations remain uninterrupted and that fabricators can continue to meet their production goals with confidence.

FAQs

What are the key features of HSG tube lasers?

HSG tube lasers feature precision cutting technology, automatic loading and unloading, and user-friendly interfaces, making them ideal for a variety of applications.

How long is the delivery timeline for these machines?

Delivery timelines vary based on the specific model and customization options, but Mac-Tech typically ensures prompt delivery and setup.

What maintenance is required for HSG tube lasers?

Regular maintenance includes routine inspections and software updates, all of which Mac-Tech can assist with to ensure optimal performance.

Are HSG tube lasers compatible with existing systems?

Yes, they are designed for seamless integration with existing workflows, minimizing disruption during the transition.

Can older equipment be traded in when purchasing an HSG tube laser?

Mac-Tech offers trade-in options for qualifying equipment, helping to offset the cost of new purchases.

What support does Mac-Tech provide post-sale?

Mac-Tech provides comprehensive post-sale support, including maintenance services and technical assistance to ensure continuous operation.

Optional: For more info: 888-MAC-9555, or find Mac-Tech on LinkedIn.

Get Weekly Mac-Tech News & Updates