I’ve been immersed in the world of machine tools and metal fabrication for more than 15 years, helping manufacturers optimize performance, reduce downtime, and boost profitability. As Regional Sales Manager for Illinois at Mac-Tech, I’ve seen firsthand how small adjustments—or major equipment overhauls—can completely transform a shop’s output, efficiency, and bottom line.

In my work, I focus on exposing the true cost of equipment downtime. I’ve published insights on this topic—most recently in “The True Cost of Machine Downtime: Why Upgrading Equipment Matters”—to help you see just how much outdated machinery might be costing you. There’s often more to it than meets the eye, and that’s where I step in to provide clear guidance.

Drawing on 15+ Years of Industry Expertise to Uncover Downtime’s Hidden Costs

I’ve spent years studying how machine reliability correlates with labor costs, fulfillment rates, and ultimately, customer satisfaction. Downtime doesn’t just cost you lost production hours; it can risk losing contracts or damaging your reputation. Ensuring you have the right mix of equipment and scheduled maintenance can dramatically reduce these setbacks.

Whether it’s a press brake that struggles to keep up with complex bends or a laser system that constantly needs recalibration, I use my in-depth experience to identify looming reliability issues. The goal is to address them before they become critical failures and disrupt production schedules in a way that eats into your profits.

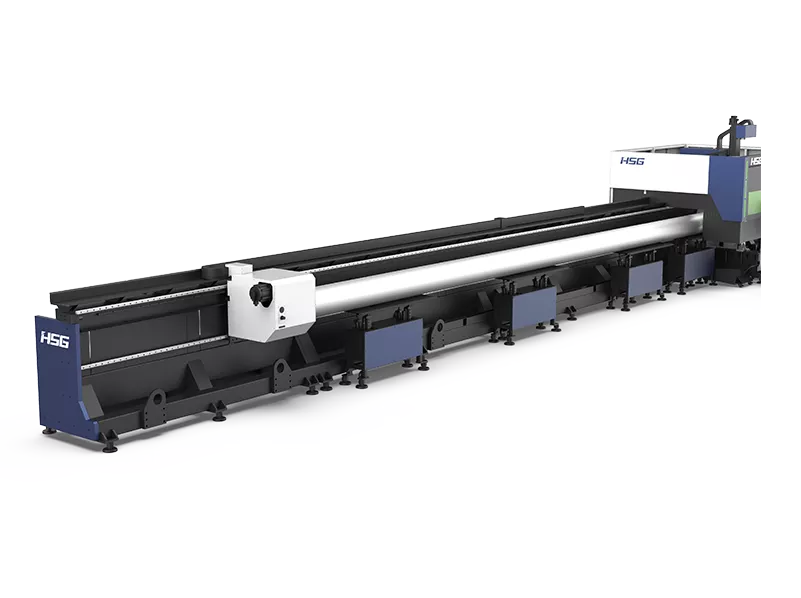

HSG TX3R PROFESSIONAL HEAVY-DUTY TUBE LASER CUTTING MACHINE

Redefining Large-Diameter Tube Processing

The HSG TX3R is built for fabricators who demand precision, speed, and efficiency when processing heavy-duty tubes and profiles. With intelligent self-centering chucks,…

DYNATORCH XLY HF 5X10

Tailored Equipment Upgrades That Align with Your Production Goals

No two shops are alike, which is why I never offer cookie-cutter proposals. By assessing your current machinery and mapping out your production forecasts, I can recommend upgrades—from advanced lasers to state-of-the-art press brakes—that genuinely align with where your business is headed.

I’ve learned that the right upgrades can pay for themselves in short order. Replacement parts, wasted raw materials, and scrap output add up quickly when equipment falters. My mission is to help you select the ideal machinery so you can boost throughput and stay competitive without overextending your budget.

Fueling Sustainable Growth Through Strategic Modernization

When you modernize intentionally, you pave the way for scalable, long-term growth. It’s not just about keeping pace with the latest technology; it’s about making informed investments that help you capture new markets and retain customers who demand precision and efficiency.

By aligning equipment capabilities with projected demand, you can avoid missed deadlines and reduce per-unit costs. This approach has allowed many of the clients I work with to expand into new product lines confidently and deliver on complex orders, solidifying their reputation in the market.

Beyond the Purchase: Mac-Tech’s Ongoing Support for Lasting Success

Upgrading your equipment isn’t a one-time event—it’s a continuous improvement process. My role at Mac-Tech involves helping you adapt to market shifts and keeping your new assets running at peak performance. That includes offering training for your team and connecting you with our in-house experts for preventive maintenance and troubleshooting.

I firmly believe in forging genuine partnerships. By maintaining regular check-ins and sharing best practices, we can prevent minor issues from snowballing into production nightmares. If you ever have a question about optimizing output, revising fabrication techniques, or implementing new software, I’m just a call or email away.

FAQ

How do I measure the ROI of a new machine upgrade?

I advise calculating your current downtime costs, maintenance expenses, and scrap rates. Compare those figures to your projected savings and improvements in throughput to see how quickly your investment pays off.

Do I need to replace all my old machines at once?

Not necessarily. I often recommend a phased approach—prioritize the equipment causing the most downtime first, then upgrade step by step with a comprehensive plan.

Does Mac-Tech offer training and support for new equipment?

Absolutely. My team specializes in onboarding and training, helping your operators hit productivity targets right from the start.

I’m here to help expose–and minimize—the hidden costs of machine downtime, empowering you to upgrade wisely and fuel real growth. Let’s connect and shape a more efficient future for your operation.

For more info: 888-MAC-9555, or find me on LinkedIn.

Get Weekly Mac-Tech News & Updates