Mac-Tech has built a reputation as a leading supplier of innovative fabrication solutions, trusted by manufacturers across the Midwest for its expertise and commitment to customer success. The HSG Fiber Laser series, particularly the scalable entry-level tube and flat cutting systems, stands out as a strategic investment for Iowa fabricators seeking to enhance precision, productivity, and future growth. These machines are engineered to deliver industry-leading quality and efficiency, positioning shops to meet today’s demands and tomorrow’s opportunities.

Unlock Precision and Speed with HSG Fiber Lasers for Iowa Fabricators

HSG Fiber Lasers are designed to meet the requirements of Iowa’s dynamic manufacturing environment, where versatility and accuracy are essential. Featuring advanced fiber laser technology, these systems provide rapid, high-precision cutting for both tube and flat sheet materials. The robust build quality and intuitive controls allow operators to achieve tight tolerances on a wide range of metals, including stainless steel, carbon steel, and aluminum.

These entry-level models are ideal for fabricators looking to move beyond traditional cutting methods without overextending their budgets. By integrating HSG Fiber Lasers, shops can significantly reduce manual handling, minimize rework, and accelerate turnaround times, all while maintaining exceptional cut quality.

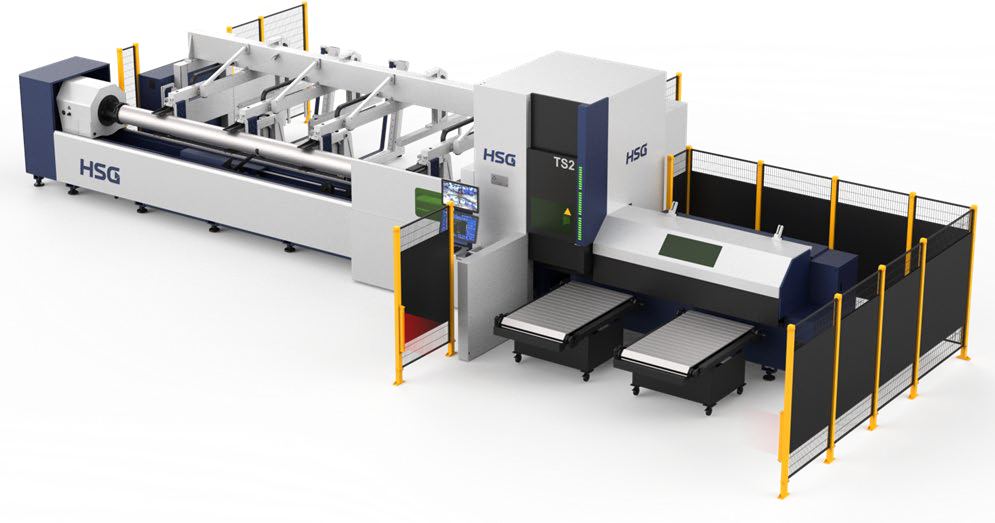

HSG TS2 V2.0 TUBE LASER CUTTING MACHINE

High-Speed Precision for Advanced Tube Processing

The HSG TS2 V2.0 delivers unmatched efficiency and accuracy in tube laser cutting. Equipped with a 6kW…

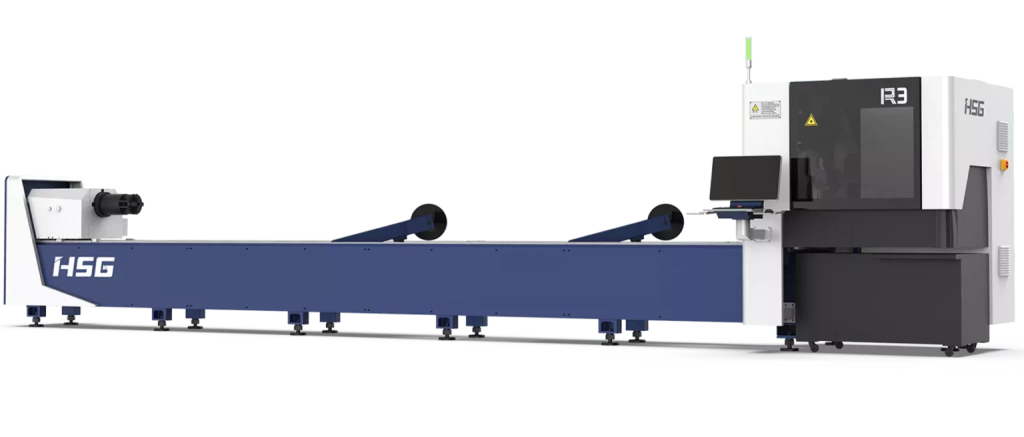

R3 PLUS-TUBE FIBER LASER CUTTING MACHINE

- Standard container transport

- Automatic loading and unloading

- HSG-X Bus control

Boost Production Efficiency with Advanced Tube and Flat Cutting Solutions

The HSG Fiber Laser systems highlighted by Mac-Tech are engineered for efficiency. With automated loading and unloading options, programmable cutting paths, and intelligent nesting software, these machines enable fabricators to maximize material utilization and throughput. Whether processing single prototypes or high-volume production runs, shops can expect consistent results and reduced operational downtime.

For Iowa manufacturers facing labor shortages or rising production costs, the automation capabilities of HSG Fiber Lasers offer a practical solution. Operators spend less time on setup and supervision, freeing up resources for value-added tasks. Mac-Tech’s expert team ensures seamless integration into existing workflows, providing training and support that empower businesses to realize rapid gains in productivity.

Achieve Superior Cutting Accuracy for Complex and High-Volume Jobs

Precision is critical for modern fabrication, especially when tackling intricate parts or demanding production schedules. HSG Fiber Lasers are equipped with high-speed servo motors, advanced focusing systems, and real-time monitoring to deliver clean, burr-free cuts with minimal heat-affected zones. This level of accuracy reduces secondary processing and ensures reliable fit-up for downstream assembly or welding.

The machines are capable of handling both round and square tubes, as well as flat sheets of varying thicknesses, making them suitable for a broad spectrum of industries, from agricultural equipment and construction to custom metalwork. By investing in HSG Fiber Lasers through Mac-Tech, Iowa fabricators gain access to technology that elevates their quality standards and competitive edge.

Maximize Your ROI with Scalable Entry-Level Systems

One of the key advantages of the HSG Fiber Laser lineup is its scalability. Entry-level models offer an economical entry point, with the ability to upgrade power sources, automation modules, and software as business needs evolve. This modular approach protects initial investments and allows fabricators to expand capabilities without the cost of a full system replacement.

Mac-Tech works closely with customers to assess their current and future requirements, recommending tailored solutions that maximize return on investment. From procurement and financing to installation and after-sales service, Mac-Tech’s end-to-end support ensures customers get the most value from their HSG Fiber Laser systems, both immediately and as their operations grow.

Expand Your Business Capabilities with Flexible, Future-Ready Technology

The manufacturing landscape is constantly changing, with new materials, tighter tolerances, and more complex geometries becoming the norm. HSG Fiber Lasers are engineered to keep pace, offering multi-material compatibility, remote diagnostics, and integration with digital factory platforms. This future-ready approach means Iowa shops can confidently take on new projects and enter emerging markets.

Flexibility is built into every HSG system, with user-friendly interfaces, quick-change fixtures, and customizable cutting programs. Mac-Tech’s team provides comprehensive training and ongoing technical support, ensuring that fabricators stay ahead of the curve and continue to deliver exceptional results, regardless of job complexity or volume.

Frequently Asked Questions

What materials can HSG Fiber Lasers cut?

HSG Fiber Lasers are compatible with a wide range of metals, including carbon steel, stainless steel, aluminum, brass, and copper, in both tube and flat sheet formats.

How quickly can a new HSG Fiber Laser system be delivered and installed in Iowa?

Delivery timelines typically range from 6 to 12 weeks, depending on configuration and availability. Mac-Tech coordinates every step, from shipping to on-site installation and operator training.

What maintenance is required for these machines?

Routine maintenance is straightforward, involving regular cleaning, lens checks, and system calibration. Mac-Tech provides detailed maintenance schedules and offers ongoing service contracts for peace of mind.

Are HSG Fiber Lasers compatible with existing CAD/CAM software?

Yes, these systems support industry-standard CAD/CAM formats and can be integrated with most production planning and nesting software platforms.

Does Mac-Tech offer trade-in or upgrade options for older equipment?

Trade-in and upgrade programs are available, allowing fabricators to offset the cost of new HSG Fiber Lasers by leveraging the value of their current machinery.

Can the entry-level systems be upgraded as production needs grow?

Yes, the modular design allows for future upgrades in laser power, automation, and software, ensuring the equipment can scale with business growth.

Optional: For more info: 888-MAC-9555, or find Mac-Tech on LinkedIn.

Get Weekly Mac-Tech News & Updates