I’m Louie Avilés, Regional Sales Manager for Illinois at Mac-Tech, and I’m thrilled to share how I elevate large-scale fabrication with high-tonnage press brakes. Over my 15+ years in machine tools and metal fabrication, I’ve honed a strong passion for integrating innovative press brake solutions into our clients’ production processes. My experience covers every facet of bending and forming—seeing firsthand how the right equipment transforms heavy-duty materials into precise, dependable parts.

I pride myself on understanding the unique challenges that fabricators in our region face. Whether it’s optimizing throughput for lengthy metal sheets or ensuring consistent angles in ultra-thick plate applications, I approach each project with enthusiasm and a dedication to problem-solving. My role is to help you harness the benefits of high-tonnage presses, maximizing your operational efficiency and opening new possibilities for groundbreaking fabrication.

Elevating Heavy-Duty Fabrication Through My 15+ Years of Press Brake Expertise

I’ve witnessed countless cases where standard press brakes simply couldn’t handle the load that heavy-duty production requires. That’s why I’ve focused on high-tonnage solutions designed to take on the toughest bending tasks. Our goal at Mac-Tech is to equip you with robust machinery that supports rapid cycle times, minimal plant downtime, and consistent part quality despite the immense forces involved.

Throughout my career, I’ve seen how the right press brake can reshape a manufacturer’s abilities, from dealing with thick steel plates for construction beams to forming large aluminum parts for aerospace applications. With each solution, I invest time to ensure you receive the product knowledge, training, and ongoing support needed to make the most of a machine that delivers unparalleled bending capacity.

Crafting Custom Bending Strategies Aligned with Your Production Goals

No two facilities are identical, and I’ve consistently found that tailor-made strategies are essential for success. Through site visits and open discussions with your production team, I pinpoint your priorities—whether it’s slashing lead times, boosting precision, or expanding your capabilities to handle thicker gauges. My objective is to employ advanced high-tonnage press brakes that tackle those specific challenges head-on.

At Mac-Tech, we also understand that client needs constantly evolve, just like the market’s demand for higher-quality and more complex formed parts. In collaboration with our expert technician teams, I’ll work with you to assess new bending techniques, software upgrades, and future automation that keep you ahead of the curve. Each step of the way, we refine your press brake strategy to capture the greatest return on your manufacturing investment.

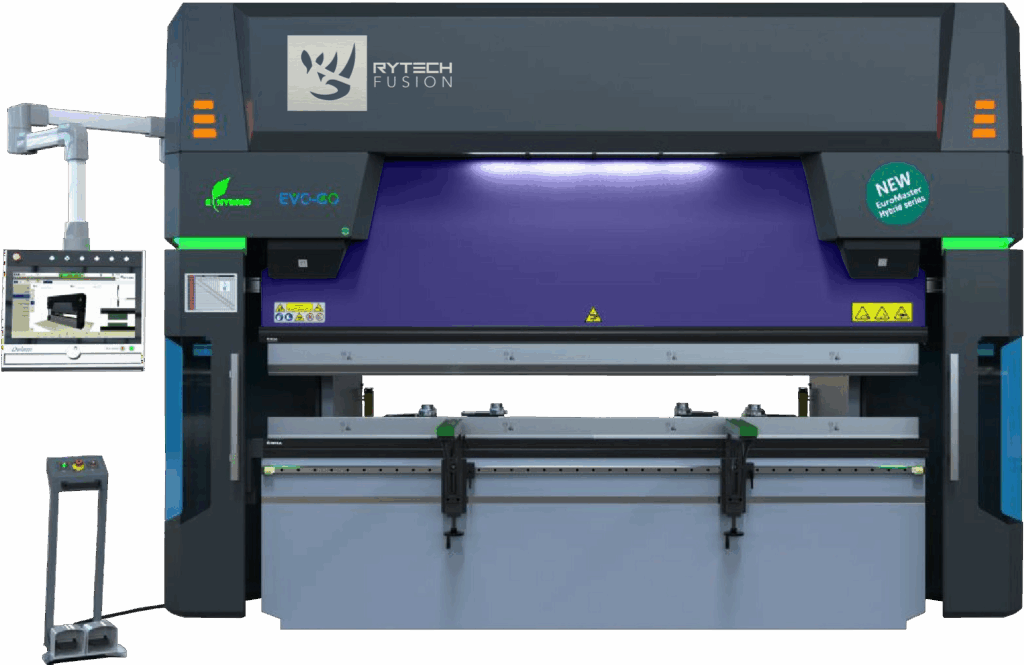

RYTECH FUSION HYBRID PERFORMANCE PRESS BRAKE

RyTech Press Brakes: Engineered for Power, Precision, and Performance

RyTech press brakes deliver exceptional bending performance across a broad spectrum of applications. With a comprehensive…

TANDEM PRESS BRAKE

Strengthening Your Process with Mac-Tech’s Ongoing, Client-Focused Support

A press brake is a long-term asset, and I’m a firm believer that strong partnerships breed long-term success. From day one of discussing needs and challenges, you can count on me and the broader Mac-Tech family to be by your side—advising on the optimal press brake tonnage, tooling setups, and any additional laser or fabrication solutions that streamline your operation.

Our clients value the fact that we don’t simply sell machines; we offer comprehensive, client-focused support that involves thorough operator training, preventive maintenance scheduling, and rapid-response service calls. Your success is my success, and Mac-Tech’s customer-centric culture empowers me to provide unmatched assistance at every stage of your press brake journey.

Ensuring Unmatched Performance in High-Tonnage Projects for Long-Term Growth

Every high-tonnage press brake we offer is put to rigorous tests to confirm it can handle the enormous forces required for large-scale bending. By integrating advanced touches such as CNC controls, automated backgauges, and specialized tooling setups, we ensure you can form parts precisely, time and time again. This consistent performance not only keeps your end products flawless but also fosters confidence among your clients and stakeholders.

My goal is to position your operation to expand into new markets and meet the most demanding fabrication tasks. Whether you’re taking on thicker, harder metals or working on oversized projects for power generation, my role is to connect you with the perfect press brake solution. The end result? A powerful synergy between operator skill, machine capability, and ongoing Mac-Tech support that sets the stage for remarkable growth.

FAQ

How do I determine the right tonnage for my press brake project?

I typically begin with an assessment of material type, thickness, and desired bend length to gauge the tonnage needed. Working closely with Mac-Tech’s experts ensures we identify the perfect press brake size and capacity for your goals.

What is the expected ROI for investing in a high-tonnage press brake?

Because heavy-duty presses allow you to handle larger parts and tougher metals, they open doors to more complex, high-value contracts. Many of my clients see a quick return through increased throughput and dependable quality.

Is specialized tooling necessary for high-tonnage bending?

Yes, and I can help you select or design tooling that handles your metal thickness and shape specifications. Proper tooling choices minimize tool wear, reduce forming errors, and save time on rework.

How do I ensure consistent precision across large workpieces?

A combination of robust press brake construction, precise CNC control, and reliable backgauges is critical. I’ll walk you through how each feature—from frame rigidity to advanced control interfaces—secures repeatable bends.

Does Mac-Tech offer preventative maintenance plans?

Absolutely. Our preventative maintenance programs help protect your equipment investment by extending life and minimizing costly downtime. It’s a critical part of keeping your operation running smoothly.

I’d love to continue our conversation about integrating a high-tonnage press brake into your production line. If you have any questions or need more details, reach out to me at louie@mac-tech.com or call 847-627-6009. Let’s elevate your fabrication capabilities together!

For more info: 888-MAC-9555, or find me on LinkedIn.

Get Weekly Mac-Tech News & Updates