As someone who grew up in the Midwest and has spent years working side-by-side with fabricators, I know how important it is to make every dollar count on the shop floor. My name is Kyle Bialozynski, Sales Executive at Mac-Tech. I’ve seen firsthand how the right equipment can transform a business, saving time, reducing headaches, and boosting profits. I believe in practical solutions—machines that actually deliver on their promises and help you get more done with less hassle. That’s exactly why I’m excited to talk to you about the Prodevco PCR42 Robotic Plasma Cutter and how it’s changing the game for structural steel shops.

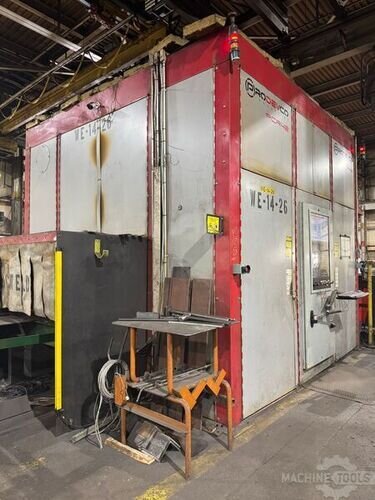

Discover Game-Changing Efficiency with the Prodevco PCR42 Robotic Plasma Cutter

If you’re like most shop managers, you’re always looking for ways to streamline operations and eliminate bottlenecks. The PCR42 is built for that purpose. This robotic plasma cutting machine automates beam coping, notches, holes, weld preps, and even splits beams—all with one setup. It can scribe and mark on all four faces of H-beams, channels, angles, HSS, and plates, which means no more flipping parts or running them through multiple stations.

What sets the PCR42 apart is its four-face operation. You can cut and mark every side of the profile in a single pass. This is a huge advantage for shops that handle complex assemblies or need to prep a lot of connection points quickly. Plus, it’s the only system in its class that can handle round tubes and pipes (from 4″ to 26″ diameter) using the same plasma coping equipment, which adds a level of versatility you won’t find elsewhere.

Unlock Greater ROI Through Advanced Automation Features

Maximizing return on investment starts with reducing labor hours and increasing throughput. The PCR42’s advanced automation features are designed for exactly that. It reads your detailing files directly—no programming required—so you can go from 3D CAD drawing to finished part with minimal input. The conveyor through-feed system and dual work zones (each with four-face operation) allow you to keep material moving, reducing cycle times and idle moments.

Unlike older systems, the PCR42 uses a non-contact laser sensor for probing, which means less wear and tear and no risk of damaging the torch or your material. The 3D vision system automatically compensates for part variation, so you get precise cuts every time, even if your material isn’t perfect. This kind of smart automation means fewer errors, less rework, and more finished parts per shift.

MODELS: PBS 700 & PBS 1000

PRODEVCO INDUSTRIES PCR42

Enhance Shop Productivity with Precision and Speed

In fabrication, time is money. The PCR42 cuts faster because of its continuous conveyor feed and dual work zones, allowing for progressive assembly and less material handling. The machine’s measuring time is shorter compared to competitors, so you spend more time cutting and less time setting up. Its robust construction and low maintenance requirements keep downtime to a minimum.

If you’re handling a high volume of structural profiles or need to switch between different shapes and sizes, the PCR42’s flexibility can be a game-changer. It’s perfect for shops looking to expand their capabilities without investing in multiple machines or adding complex workflows. The enhanced speed and accuracy directly translate into more jobs completed and more satisfied customers.

Experience Seamless Integration and User-Friendly Operation

One of the most common concerns I hear from shop managers is about the learning curve on new technology. The PCR42 is designed to be up and running fast. Most operators can learn the interface in less than a day, thanks to its intuitive controls and straightforward software. There’s no need for advanced programming skills or specialized training.

Integration with your existing workflow is seamless. The PCR42 works directly from DSTV files generated by your detailing software. Our ProEVS software even allows you to view, edit, and create new part drawings as needed. The small footprint and versatile layout options make it easy to fit into your current shop setup, whether you’re tight on space or planning future expansions.

Rely on Expert Support and Real-World Insights for Your Investment

At Mac-Tech, we pride ourselves on real-world support. The PCR42 comes equipped with onboard cameras, so our technicians can help you remotely if you ever need assistance. We’re just a call or click away, ready to walk you through troubleshooting or help you get the most out of your investment.

We understand that investing in new equipment is a big decision. That’s why we’re committed to providing honest advice, clear answers, and practical solutions based on years of experience in the field. Whether you’re looking to boost productivity, cut costs, or expand your capabilities, we’re here to help you make the smartest choice for your shop.

Frequently Asked Questions

How quickly can my team get up to speed with the PCR42?

Most operators are comfortable with the system in less than a day, thanks to the intuitive interface and simple controls.

What types of profiles and materials can the PCR42 handle?

The PCR42 processes H-beams, channels, angles, HSS, plates, and even round tubes and pipes between 4″ and 26″ diameter.

How does the PCR42 improve shop efficiency compared to traditional systems?

It automates multiple processes in a single pass, reduces material handling, and shortens cycle times with continuous conveyor feeding and dual work zones.

Is there a lot of maintenance required?

No. The PCR42 is built with robust components and requires very little maintenance.

Do I need special programming or software knowledge to run the machine?

No programming is needed. The PCR42 works directly from your DSTV files and integrates easily with your detailing software.

What kind of support can I expect from Mac-Tech?

We offer remote diagnostics, training, and ongoing support to ensure you get the best performance from your PCR42.

Is the PCR42 a good fit for smaller shops or only for large operations?

The small footprint and flexible layout make it a strong choice for both small and large shops looking to maximize capacity and efficiency.

If you have questions, want to see the PCR42 in action, or just want to talk through your current fabrication challenges, I’m here to help. No pressure—just honest advice and practical solutions tailored to your shop’s needs. Reach out anytime, and let’s see how we can take your productivity to the next level.

Get Weekly Mac-Tech News & Updates