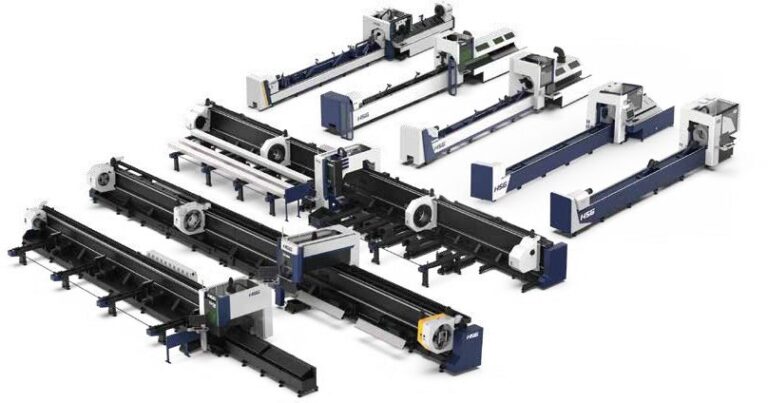

Tube Laser Efficiency in Minnesota: HSG 3000W vs 6000W Comparison for Smart ROI and Growth Decisions

Kyle Bialozynski leverages field expertise and a customer-first approach to compare HSG tube lasers, guiding Minnesota fabricators toward smart, growth-driven ROI. Kyle Bialozynski – Sales Executive, Mac-Tech kyle@mac-tech.com | 414-704-8413