Labor shortages and throughput constraints are hitting structural fabrication at the worst possible time, when bridge, shipyard, tower, and oil and gas projects are already carrying aggressive delivery dates and penalty-driven schedules. The operational reality is that a few hours of downtime on a key line, or a misaligned handoff between material handling and processing, can cascade into multi-week schedule slip. As Regional Sales Executive at Mac-Tech, I act as the trusted advisor and single point of contact who coordinates turnkey automation and ROI-focused delivery across multiple vendors, trades, and internal stakeholders so projects install, start up, and run as planned.

Multi Vendor Integration Failure Modes in Structural Automation Programs

Multi-vendor automation programs slip when individual scopes are technically correct but operationally incompatible, creating hidden queues, rework loops, and commissioning delays. The executive problem is predictable delivery: missed milestones translate to extended rentals, overtime, and lost production slots, not just an “integration issue.”

Common failure points that cause schedule slip

- Layout conflicts discovered late (forklift aisles, crane envelopes, infeed clearances): 2–6 weeks redesign and rework risk

- Electrical and controls mismatches (I/O mapping, network standards, safety circuits): 40–120 commissioning hours added

- Material flow bottlenecks between processes (manual staging between drill, beam coping, plasma/laser, and marking): 1–2 shift equivalent lost capacity

- Training gaps across different HMIs and procedures: 15–30% slower ramp-up during first 4–8 weeks

- Documentation fragmentation (multiple manuals, wiring sets, and spare parts lists): 2–4 touchpoints per issue before resolution

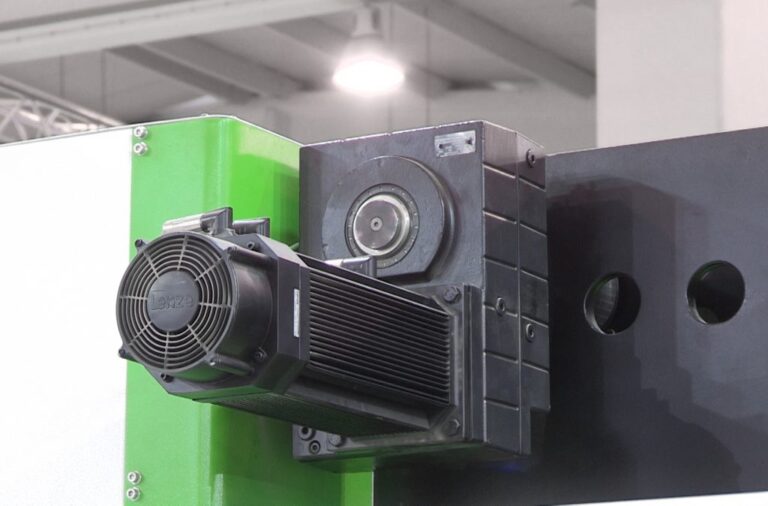

ERMAKSAN POWER-BEND FALCON BENDING MACHING

ERMAKSAN SPEED BEND PRO

Decision Criteria for Assigning Structured Ownership Across Vendors and Trades

Assigning structured ownership is a business decision to reduce variability, protect uptime, and ensure schedule reliability when multiple machines and contractors must work as one system. Ownership should go to the party best positioned to coordinate scope, interfaces, and accountability, not simply the party with the largest equipment line item.

Decision criteria that support predictable outcomes

- Number of interface points (mechanical, electrical, controls, and IT): target 1 owner for 5+ critical interfaces

- Critical path impact: any system that can stop downstream production should be governed with milestone-based acceptance

- Commissioning complexity: projects requiring 80+ hours of start-up benefit from unified commissioning plans and signoffs

- Service continuity needs: facilities targeting 85–95% utilization need a single escalation path and consolidated spares planning

- Change frequency: programs with weekly drawing revisions require controlled documentation and structured change control to prevent rework

Ownership Models That Reduce Integration Risk With a Single Point of Contact

The most effective model is a single integration owner who coordinates OEMs, installers, and plant stakeholders, backed by milestone gates and documented acceptance criteria. This does not replace vendor expertise, it prevents gaps between vendors from becoming your problem.

Practical ownership models

- Integration Owner model (one-call accountability): one coordinator manages layout, interface definitions, commissioning sequence, and signoff

- Prime contractor with sub-vendor governance: useful when civil and utilities are major scope drivers, with defined equipment acceptance gates

- Internal owner plus external integrator: works when the plant has controls engineering bandwidth to manage I/O, networks, and safety validation

When appropriate, machine selection should also reduce integration friction by standardizing controls and flow. For example, pairing a Prodevco structural processing system with upstream/downstream material handling, or introducing HSG Fiber Lasers where cutting speed and edge quality reduce downstream grinding, can remove manual touchpoints that typically create scheduling and quality variability.

Implementation Risks and Controls Under Dave Graf as Integration Owner

My role is to make integration predictable by owning the interfaces, sequencing, and documentation, from initial layout to long-term service continuity. The executive goal is fewer surprises: schedule certainty, safer commissioning, and stable production ramp-up across all systems and vendors.

Controls I put in place to protect schedule and uptime

- Interface matrix (mechanical, electrical, controls, safety): 100% of interfaces assigned an owner and due date before PO release

- Milestone gates with acceptance criteria: FAT completion, site readiness, rigging plan signoff, power-on, first part, rate validation

- Commissioning runbook with hour-by-hour sequencing: reduces idle contractor time by 10–20% and limits rework loops

- Training plan tied to roles and shifts: operator and maintenance training scheduled to support 2–3 shift operations, not just day shift

- Service continuity plan: consolidated spare parts list, escalation path, and PM intervals aligned to utilization targets

- Change control discipline: revision tracking, RFIs, and scope decisions logged so field changes do not become recurring defects

For equipment solutions, I help ensure the process chain is designed for throughput rather than isolated machine performance, whether that includes Liberty, Ermaksan, Akyapak, Ercolina, or other systems where fit is operationally justified. When you want a clear view of configurable options and accessories that affect integration, the Mac-Tech online catalog is a practical reference point: https://shop.mac-tech.com/

Measurable Outcomes for Predictable Delivery, Quality, and Change Control

Structured ownership is successful when it produces measurable operational outcomes, not just smoother meetings. The business result is predictable delivery, stable utilization, and fewer production interruptions during ramp-up.

Outcomes fabricators can track in the first 90–180 days

- Commissioning duration reduction: 20–40% fewer start-up hours due to defined sequencing and interface signoff

- Reduced unplanned downtime during ramp: 10–25% improvement through unified service escalation and spares readiness

- Lower rework and rehandling: 15–30% reduction by eliminating manual staging and inconsistent process handoffs

- Higher utilization on constrained resources: +5–12 points by reducing queue time and standardizing changeover procedures

- Change control performance: fewer field revisions and faster approvals, with 1 owner responsible for documentation updates and closeout

Next Steps for Structural Fabricators to Operationalize Structured Ownership

Start by defining the operational target, then engineer the integration plan around it. The fastest path to predictable delivery is aligning your project milestones, acceptance criteria, and documentation before equipment hits the floor.

A practical approach to start now

- Map the value stream and quantify constraints: queue time, manual touchpoints, and current rework rate by shift

- Establish an interface matrix and milestone gates before finalizing layout and utilities: reduce redesign risk by weeks

- Select equipment based on system throughput and handling, not just single-machine speed: validate infeed, outfeed, and staging

- Assign one integration owner and one escalation path for the full program: reduce touchpoints and shorten time-to-resolution

If you want to explore system configurations and integration-sensitive options in one place, start with https://shop.mac-tech.com/ and use it to anchor your internal requirements discussion.

FAQ

What lead times should executives expect for multi-system structural automation?

Lead times vary by machine class and options, but the bigger driver is site readiness and interface clarity. I set milestone-based schedules so procurement and site work stay aligned.

How do you reduce the risk of commissioning overruns?

I use an interface matrix, commissioning runbook, and acceptance gates so issues are identified before power-on. This typically prevents 40–120 hours of avoidable debugging across vendors.

What does training look like for multi-vendor lines across multiple shifts?

Training is role-based and shift-aware, with operator, programmer, and maintenance tracks scheduled to support real production coverage. I coordinate vendor trainers so procedures and safety practices are consistent.

How is maintenance planning handled when equipment comes from multiple OEMs?

I consolidate PM intervals, spare parts priorities, and escalation paths into one service continuity plan. The goal is one call to triage and coordinate, not multiple parallel tickets.

How do we protect uptime during the first 60–90 days after launch?

We stage spare parts, confirm utility stability, validate safe material handling, and run rate verification before declaring steady-state. I coordinate follow-up visits and remote support alignment so early issues do not linger.

How should ROI be measured beyond machine cycle time?

I recommend tracking throughput per shift, labor redeployment, queue time reduction, rework rate, and unplanned downtime. These metrics reflect the whole system performance and schedule reliability.

Contact me for layout planning, demonstrations, or full project coordination: dave@mac-tech.com | 602-510-5552 | https://shop.mac-tech.com/

Get Weekly Mac-Tech News & Updates