C & G CHALLENGER DSD 6X12

C & G CHALLENGER DSD 6X12

Description

Description

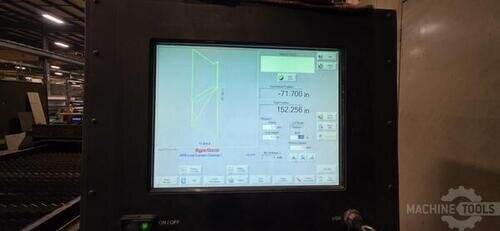

Heavy-Duty Dual-Side Drive Versatile and Expandable The Challenger is your best value for high-production conventional or precision plasma, as well as heavy-duty oxy-fuel cutting applications. A time-proven design featuring sturdy, long-lasting components will boost your production to new levels. The Challenger is available in standard cutting widths of 6’ x 12’ (3.7m) effective cutting length. CNC Controls: Challenger DXD is available with Hypertherm EDGE Connect CNC Control. This industrial PC-based control runs in a user-friendly yet powerful Windows 10 environment and has a 19.5” Projected Capacitive (PCAP) touch-screen.

Heavy-Duty Construction The new Challenger DXD series builds on the time-tested Challenger platform. A powerful dual-side drive system replaces the traditional single-side drive, riding on precision-machined and flame-hardened tongue-in-groove 90# T-Rails mounted on 6” x 8” (150mm x 200mm) steel tube pedestals. To ensure smooth and accurate motion, crowned truck wheels with self-cleaning wipers are used. The Rail Axis features a Helical Rack-and-Pinion Drive System, and the cross axis uses 25 mm High-Speed Self-Lubricating Linear Bearings. Challenger DXD also includes a Clean Deck design for maximum cable and hose protection and easy maintenance access.

Plasma Productivity The Sensor THC integrated torch height control system from Hypertherm is standard, ensuring precise pierce heights and consistent torch-to-plate distance for optimal cut quality. Challenger DXD supports a wide range of conventional or precision plasma systems up to 400 amps from Hypertherm, enabling cutting up to 2″ in steel, stainless steel, and aluminum. Built around Hypertherm’s SureCut Technology—including True Hole and Rapid Part—the system delivers superior hole quality and dramatically improved productivity. The machine can be equipped with Hypertherm’s XPR 170, XPR 300, or HPR-400XD plasma systems. Oxy-Fuel Performance: Challenger DXD can also support up to four oxy-fuel stations, with heavy-duty components for high performance. The optional gas system provides fast pierce rates, balanced torch flames, and exceptional oxygen flow capacity. The standard Victor MT318 torch cuts plate up to 12” (300mm) thick.

Specifications

Specifications

SPECIFICATIONS

| Cut-Width | 6′ |

| Cut-Length | 12′ |

| Plasma Power | 400 a |

| # Plasma Torches | 1 |

| Control | CNC (HYPERTHERM EDGE-PRO) |

Equipped With

Equipped With

EQUIPPED WITH

- Industrial PC-Based Hypertherm EDGE Connect CNC Controller

- Integrated Sensor Torch Height Control System

- Easy-To-Use 19.5” PCAP Touch Screen Operation

- Windows 10 Based Operating System

- Solid State Hard Drive – USB Ports

- 750 Watt AC Dual-Side Servo Drives

- Up To 600 IPM

Spec Sheet

Spec Sheet

SPEC SHEET

- Standard Cutting Widths of 6

- Standard Effective Cutting Length is 12’ (3.7m).

- Welded Steel Construction

- Hypertherm HPR400XD Plasma Torch

- Water Table (Raise / Lower)

Finance

Why Finance Your Equipment with Tech Financial?

Financing your equipment through Tech Financial unlocks a world of possibilities for your business. With flexible payment plans, tailored solutions, and quick credit approvals, you can preserve working capital while accessing the latest technology to stay competitive. Enjoy potential tax advantages, affordable rates, and a seamless application process designed to get you the equipment you need without delays. Tech Financial’s expertise and customer-focused approach make investing in your business’s future easier and more cost-effective than ever.

Ready to get started? Apply today and take the next step toward smarter financing!