As a Sales Executive at Mac-Tech, I bring a strong Midwest work ethic and a deep understanding of the challenges faced in structural fabrication. My role is to bridge the gap between cutting-edge technology and practical shop floor solutions. With a focus on real-world applications, I’m here to help you navigate the complexities of modern fabrication with precision and profitability in mind.

Enhance Precision with HSG Tube Lasers

In the world of structural fabrication, precision is paramount. HSG Tube Lasers replace the traditional multi-step cutting and drilling processes with automated precision. Unlike conventional saws, these lasers offer exact cuts every time, reducing errors and ensuring consistent quality. For any shop aiming to maintain high standards, this technology is a game-changer.

By integrating HSG Tube Lasers, you eliminate the need for multiple machines and manual adjustments. This streamlined approach not only enhances precision but also minimizes the chances of human error. The result? A smoother, more reliable production process that delivers exact results.

Maximize Efficiency and Reduce Waste

Efficiency is the backbone of profitability, and HSG Tube Lasers excel in this area. Traditional saws often lead to material waste due to inaccurate cuts and the need for additional processing. In contrast, tube lasers deliver precise cuts that maximize material usage.

This technology significantly reduces scrap and optimizes your material inventory. With less waste, your bottom line improves while contributing to more sustainable practices. Additionally, the reduced need for rework accelerates project timelines, allowing you to meet tight deadlines with ease.

TLS HIGH-SPEED FULLY AUTOMATIC LASER CUTTER

- Heavy Duty Tube Processing Ability

- Innovative 4+1 Chuck Structure

- Intelligent Digital Chuck

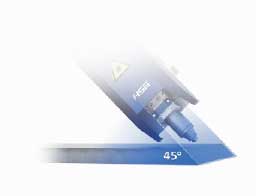

- Bevel Processing

TL FOUR-CHUCK HEAVY-DUTY TUBE FIBER LASER CUTTING MACHINE

- Four Chuck Structure

- Automatic Loading and Unloading

- HSG-X Bus Control System

- Tube Splicing Technology

Boost Profit Margins through Advanced Fabrication

Investing in HSG Tube Lasers can have a profound impact on your profit margins. By reducing cycle times and increasing output, these machines allow you to take on more projects without compromising quality. The automation of cutting and drilling processes translates to lower labor costs and higher throughput.

Furthermore, the precision of HSG Tube Lasers means fewer rejected parts and less time spent on corrections. This efficiency directly contributes to higher profitability, making your operations more competitive in the market.

Elevate Project Turnaround with Cutting-Edge Technology

Meeting project deadlines is critical in structural fabrication. HSG Tube Lasers offer a significant advantage by reducing cycle times. Traditional methods often involve multiple steps and machine setups, leading to delays. Tube lasers, however, complete tasks in a fraction of the time, allowing for quicker project turnaround.

This speed not only satisfies your clients but also enables you to take on additional work. Faster project completion means increased capacity and the ability to scale your operations effectively.

Gain a Competitive Edge with Innovative Solutions

In an industry where staying ahead is key, adopting innovative solutions like HSG Tube Lasers can set you apart from competitors. These machines offer unparalleled accuracy and efficiency, positioning your business as a leader in quality and reliability.

By embracing this technology, you’re not just improving your current operations; you’re investing in the future of your business. The ability to deliver superior products consistently will enhance your reputation and attract more clients.

Experience Unmatched Support and Expertise from Mac-Tech

At Mac-Tech, we pride ourselves on providing exceptional support and expertise. Our team is dedicated to helping you maximize the potential of HSG Tube Lasers. From installation to ongoing maintenance, we’re here to ensure your machines operate at peak performance.

We understand the logistical challenges of integrating new technology, which is why we offer comprehensive training and support. Our goal is to make the transition as seamless as possible, so you can focus on what you do best—producing high-quality structural fabrications.

FAQ Section:

What are the main benefits of using HSG Tube Lasers over traditional saws?

HSG Tube Lasers offer precision, reduced waste, and faster cycle times, improving overall efficiency and profitability.

How do tube lasers reduce material waste?

Precision cutting maximizes material usage, reducing scrap and optimizing inventory.

Are tube lasers cost-effective for small operations?

Yes, they reduce labor costs and increase throughput, making them a smart investment for shops of all sizes.

What support does Mac-Tech offer for new machine installations?

We provide comprehensive training and ongoing maintenance support to ensure seamless integration.

How quickly can I expect a return on investment with tube lasers?

The increased efficiency and reduced waste typically lead to a quick ROI, often within a few months.

If you have any questions or need further assistance, I’m here to help. Feel free to reach out for more information or to discuss how we can enhance your operations.

Get Weekly Mac-Tech News & Updates