As a proud Midwesterner and Sales Executive at Mac-Tech, I’ve spent years working with Wisconsin’s fabrication shops to solve real-world production challenges. My roots in the Midwest have instilled in me a strong work ethic and a commitment to delivering practical solutions that enhance efficiency and profitability. I understand the unique demands of our industry, and I’m here to share how automating beam coping with Prodevco Robotics can transform your operations.

Discover How Automated Beam Coping Transforms Wisconsin’s Fabrication Industry

In Wisconsin, fabrication shops have long relied on manual beam coping, a process that often creates bottlenecks and slows down production. With Prodevco Robotics, these manual hurdles become a thing of the past. By automating beam coping, you can streamline operations and eliminate the inefficiencies that come with manual labor.

Imagine a system where precision meets speed, and human error is minimized. Prodevco Robotics offers cutting-edge technology that not only increases the speed of beam processing but also ensures consistent quality. This transformation is not just about keeping up with the competition; it’s about leading the way in innovation and efficiency.

Maximize Efficiency with Prodevco Robotics: A Hands-On Approach

Prodevco Robotics provides a hands-on approach to automation that’s perfect for shops looking to enhance their productivity. By integrating these machines into your workflow, you can significantly reduce the time spent on manual tasks and focus on more strategic operations.

The machines are designed with user-friendly interfaces and robust software that allow for easy integration into existing systems. They require minimal training, meaning your team can adapt quickly and start seeing benefits almost immediately. With Prodevco, you gain more than just a machine; you gain a partner in efficiency.

Boost Your Bottom Line: Leveraging Section 179 for Immediate ROI

One of the most compelling aspects of investing in Prodevco Robotics is the financial benefit offered by Section 179 of the IRS tax code. This allows businesses to deduct the full purchase price of qualifying equipment, making automation not only an operational advantage but a financial one too.

By taking advantage of Section 179, you can reduce your tax liability and see a quicker return on your investment. This deduction makes it possible for shops to invest in advanced technology without the burden of a hefty upfront cost, allowing for better cash flow management and financial planning.

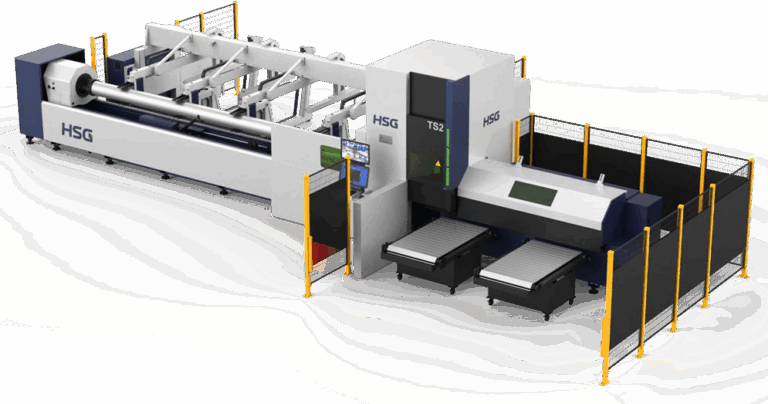

AFD Plate Drilling Machines

Experience Growth: Real Success Stories from Wisconsin Fabricators

Wisconsin fabricators have already started to reap the benefits of Prodevco’s automation solutions. Shops have reported significant reductions in lead times and increased throughput, leading to better customer satisfaction and more business opportunities.

For example, a local fabricator in Milwaukee saw a 30% increase in production capacity within just a few months of implementing Prodevco Robotics. This growth was not just in volume but also in the quality of output, enabling them to take on more complex projects and expand their client base.

Personalized Solutions: Tailored Automation Strategies for Your Business

Every fabrication shop is unique, with specific needs and challenges. That’s why Prodevco Robotics offers tailored automation strategies to fit your business. Our team works closely with you to understand your workflow and identify the best solutions.

Whether you’re dealing with space constraints or specific technical requirements, Prodevco Robotics can customize a plan that aligns with your goals. This personalized approach ensures that you get the maximum benefit from your investment in automation.

FAQ Section:

What are the primary benefits of automating beam coping?

Automating beam coping increases efficiency, reduces errors, and accelerates production timelines.

How does Section 179 impact my investment in Prodevco Robotics?

Section 179 allows you to deduct the full purchase price of the equipment, offering significant tax savings.

Is the transition to automation difficult for my team?

The machines are designed for ease of use, requiring minimal training for a smooth transition.

What kind of ROI can I expect?

Many shops experience a noticeable increase in production capacity and quality within months.

Are there specific space requirements for these machines?

Prodevco Robotics can tailor solutions to fit various shop sizes and layouts.

If you’re ready to explore how automating beam coping can enhance your operations, I’m here to help. Feel free to reach out with any questions or for sales support. Let’s take the next step in optimizing your fabrication process together.

Get Weekly Mac-Tech News & Updates