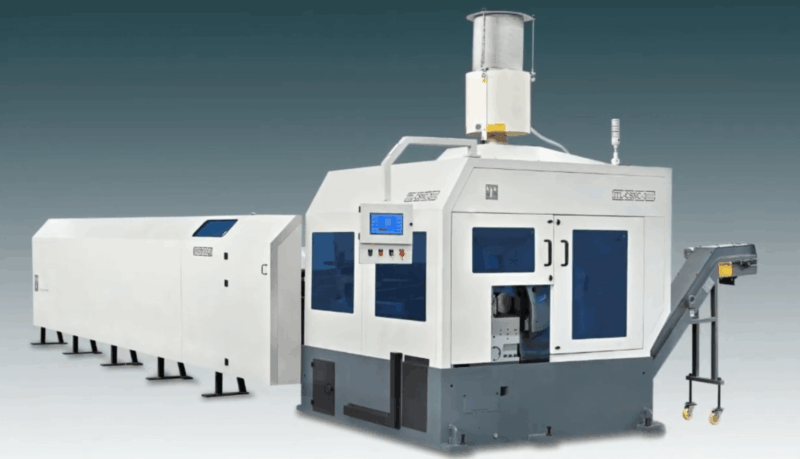

HYDMECH CSNC-65

Does the Work of Five Conventional Band Saws!

A highly efficient and productive saw designed for use with a carbide tipped blade

A superior sawing solution supported by top-of-the-line service technicians and a well-stocked parts department to keep your production going strong!

Designed and built with off-the-shelf parts easily found at local suppliers and supply houses for quick repairs.

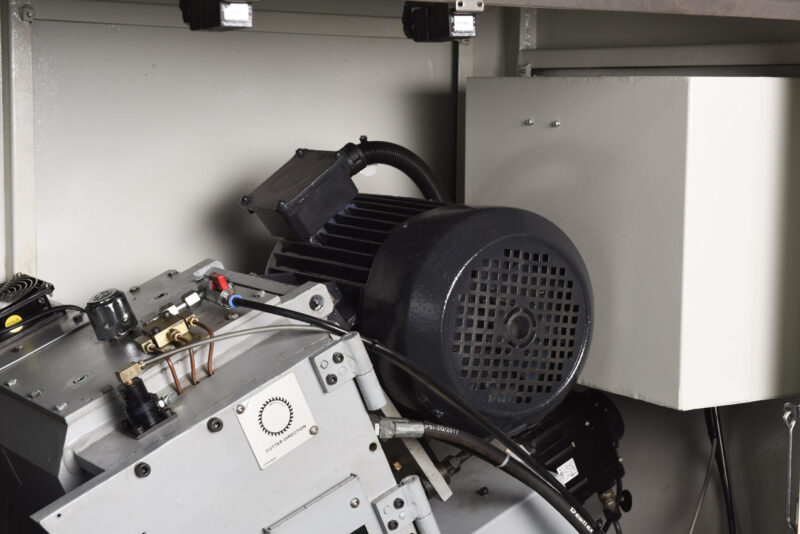

Featuring a 0.4” – 2.55” round capacity at 90°, 10 HP motor, and a 250 mm blade, the CSNC-65 is a versatile high-speed cutting machine.

HYDMECH CSNC-65

Description

Description

Does the Work of Five Conventional Band Saws!

Specifications

Specifications

| Cutting Capacity Round 90° | 0.4″-2.55″ |

| Cutting Capacity Square 90° | 0.4″-1.96″ |

| Blade Drive | 10 HP VFD |

| Blade Speed | 164-656 SFM |

| Blade Size | Carbide/Cermet tipped: 9.8″ x 0.08″ kerf |

| Bar Stock Length | 10′-20′ |

| Trim Cut | Zero or programmable from 0.4′ or longer |

| Cut off Length | Min 0.24” up to 39” |

| Single Stroke | 20″ |

| Remnant Length | 1.57” + cut length + blade thickness |

| Hydraulic Motor | 3 HP |

| Bar Loading Magazine | Inclined storage width of 27.9″ for rounds |

| Machine Capacity | 4400 lbs. |

| Machine Weight | 5500 lbs. |

| Dimensions (w x l x h) | 77” x 98” x 75” |

Standard Features

Standard Features

STANDARD FEATURES

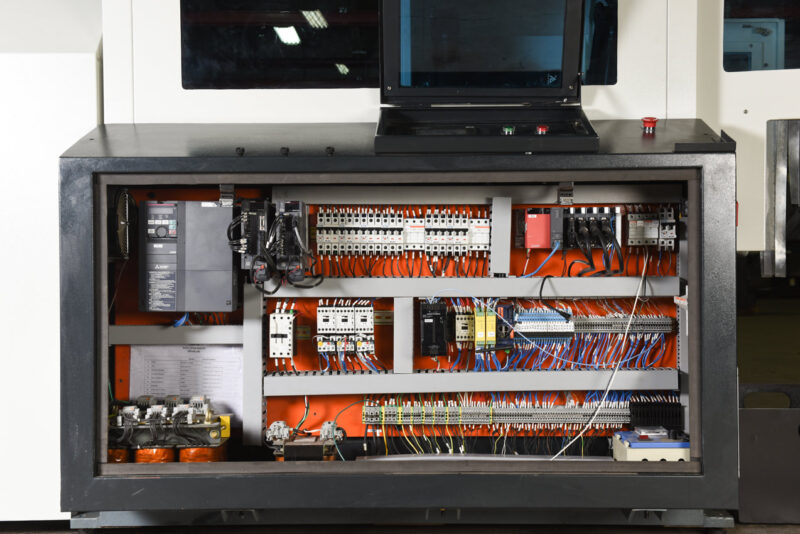

- Mitsubishi PLC Controller allows for 200 programs to be saved

- Job monitoring with cycle time, job duration, parts count and AMP load setting to protect the saw blade.

- Material library with US steel grades menu with ability to add custom material grades

- Bar feed and roller table with a material gripper feed carriage indexing via ball screw and AC servo drive. Shuttle speed: 7.87” per second

- Heavy duty saw head is driven by ball screw and AC servo drive with horizontal and vertical clamping

- Mist exhaust system

- Patent pending blade cooling system.

- Bar retracts automatically for contact free return stroke of the saw blade

- Universal Bar Loader for round and square material with safety guard sheets provides inclined storage width of 27.9” (710 mm) for rounds, manual incline setting. Capacity: 3,747 lbs.

- PLC controller, automatic oil lubrication of all moving parts

- Output sorting ensures trim cuts and remnant pieces are sorted automatically from good parts

- Variable vise pressure control with dial gauge – two stations

- Blade lubrication features triple jet system to lubricate blade. If the coolant level gets low, the machine will alarm to alert the operator.

- Hydraulic rotating wired chip brush rotates in both directions for proper chip removal

- Status light indicating tower

- Chip auger

- Air cooled electric magnetic head break removes all backlash.

- Built in hydraulic tank and power pack

- Tool steel hardened saw guide plates

- Power transformer

- Four blade starter package

- Blade specs: 250 mm x 2.0 kerf x 1.70 mm body x 32 mm bore

- Pin holes: 4/9/50 mm

- Bolt holes: 4/11/63 mm

Optional Features

Optional Features

OPTIONAL FEATURES

- Universal hydraulic incline adjustment bar loader – 20′

- PLC program modification

- 2 ton- chain and finger bundle unscrambler

- Chain chip conveyor

- Maintenance Kit

- Motorized sliding out-feed conveyor table and guarding in the following lengths – 1000 mm, 2000 mm, and 3000mm

Finance

Why Finance Your Equipment with Tech Financial?

Financing your equipment through Tech Financial unlocks a world of possibilities for your business. With flexible payment plans, tailored solutions, and quick credit approvals, you can preserve working capital while accessing the latest technology to stay competitive. Enjoy potential tax advantages, affordable rates, and a seamless application process designed to get you the equipment you need without delays. Tech Financial’s expertise and customer-focused approach make investing in your business’s future easier and more cost-effective than ever.

Ready to get started? Apply today and take the next step toward smarter financing!