From the shop floors of southern Chicago to the innovation-driven environment at Mac-Tech, my journey has always been about helping customers build smarter, more efficient operations. With decades of hands-on experience, I’ve seen how the right investment in technology—especially in CNC folders—can turn a bottlenecked trim department into a model of productivity. My role as Regional Sales Executive isn’t just about selling equipment; it’s about partnering with you to evaluate, select, and implement solutions that deliver results for your metal building business.

Leveraging Decades of Expertise: How CNC Folders Are Transforming Trim Work Efficiency

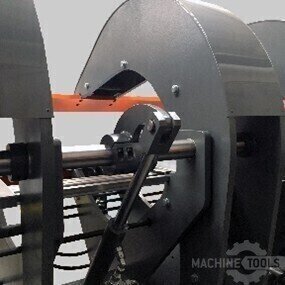

In the metal building industry, trim work is both an art and a science. Historically, fabricators relied on manual brakes and labor-intensive processes, leading to inconsistencies and frequent rework. Today, CNC folders have revolutionized this space by allowing a single operator to manage complex folds with precision and repeatability. At Mac-Tech, we’ve helped countless customers transition from legacy systems to automated CNC solutions, consistently seeing gains in throughput, product quality, and labor efficiency.

Identifying Inefficiencies in Coil-Fed Metal Building Production

Many shops still struggle with outdated coil handling, manual slitting, and slow folding operations. Common pain points include excessive setup times, operator fatigue, scrap from misaligned folds, and the need for multiple workers to manage each job. These inefficiencies not only drive up labor costs but also limit your ability to scale production or respond to custom orders quickly.

Evaluating Your Current Slitting, Forming, and Folding Capabilities

A thorough production audit is the first step. I work closely with customers to review every stage—from decoilers and slitters to shears, folders, and downstream handling. Key questions include:

- Are your slitters producing clean, burr-free edges at speed?

- Is your folder capable of handling today’s more complex trim profiles?

- How much downtime do you experience during changeovers or maintenance?

By benchmarking your current equipment against industry standards and best practices, we can pinpoint where automation or upgrades will have the greatest impact.

Key Performance Metrics: Speed, Accuracy, and Waste Reduction

Modern CNC folders stand out in three critical areas:

- Speed: Automated tool changes and programmable sequences slash cycle times, enabling one operator to do the work of a traditional crew.

- Accuracy: CNC control delivers repeatable bends within tight tolerances, drastically reducing scrap and rework.

- Waste Reduction: Optimized nesting and folding routines maximize material yield, lowering cost per part.

We help customers compare metrics like parts per hour, first-pass yield, and material utilization before and after upgrades—so you can see the ROI in black and white.

Upgrading to Advanced CNC Folding Solutions: A Step-by-Step Guide

- Assessment: We start with an on-site evaluation of your current workflow and equipment.

- Specification: Based on your trim profiles, coil widths, and production volume, we recommend the right CNC folder—evaluating brands, features, and integration options.

- Demo & ROI Analysis: Live demonstrations (in-person or virtual) and detailed ROI calculations give you confidence in the investment.

- Installation & Integration: Our team ensures seamless installation and integration with existing slitters, shears, and roll formers.

- Training & Support: We provide hands-on training for operators and ongoing technical support to keep your line running at peak efficiency.

Customizing Equipment to Meet Unique Trim Fabrication Needs

No two metal building shops are exactly alike. Whether you’re running architectural panels, agricultural trim, or custom profiles, we tailor equipment recommendations to your specific needs. Options include:

- Servo-driven folders for high-speed, high-precision applications

- Combi-beam or double folder configurations for greater flexibility

- Integrated slitters, shears, and automated stacking to streamline workflows

I’ve helped customers configure lines that handle everything from 26-gauge steel to heavy-gauge aluminum, with quick changeovers and minimal downtime.

Real-World Results: Client Success Stories in Metal Building Trim Production

One Midwest customer replaced three manual brakes with a single CNC folder, reducing labor needs by 60% and doubling output within weeks. Another client integrated a new decoiler, slitter, and folder line, cutting scrap rates by 30% and achieving consistent part quality across multiple shifts. These are just a few examples of how the right investment can transform your business.

Maximizing ROI: Ongoing Support and Training for Sustainable Efficiency

Upgrading to CNC folding is only the beginning. At Mac-Tech, we’re committed to your long-term success. Our support includes:

- Preventive maintenance programs

- On-site and remote troubleshooting

- Operator refresher courses

- Upgrades and retrofits as your needs evolve

This partnership approach ensures that your investment continues to deliver value for years to come.

Frequently Asked Questions

When is the right time to upgrade a roll former or folder?

If you’re experiencing frequent breakdowns, excessive scrap, or can’t keep up with demand, it’s time to consider an upgrade. We also recommend evaluating your equipment if you’re adding new trim profiles or expanding production capacity.

How do servo-driven folders compare to hydraulic systems?

Servo-driven folders offer faster cycle times, greater energy efficiency, and more precise control over bend angles—making them ideal for high-volume or complex trim work.

What’s the difference between a combi-beam and double folder?

A combi-beam folder uses interchangeable tooling for flexibility, while a double folder bends in both directions without flipping the part, which speeds up production and improves accuracy for complex profiles.

What are signs a roll forming line is no longer cost-effective?

Look for increased downtime, rising maintenance costs, inconsistent product quality, or difficulty adapting to new profiles. If these issues persist, it’s likely time to explore newer, more efficient solutions.

Can CNC folders handle non-standard or custom trim profiles?

Absolutely. Modern CNC folders can be programmed for a wide variety of custom shapes, ensuring your shop can respond to unique customer requests quickly and accurately.

How long does it take to train operators on new CNC folding equipment?

Most operators are up and running within a few days, thanks to intuitive controls and our comprehensive training programs. Ongoing support ensures your team stays confident and productive.

If you’re ready to see what CNC folding can do for your trim department, let’s talk! Whether you’re looking for a walkthrough, a live demo, or a detailed upgrade quote, I’m here to help you every step of the way.

Get Weekly Mac-Tech News & Updates