In the structural steel fabrication industry, margins are tighter than ever, and the demand for faster throughput is at an all-time high. I’ve seen too many companies struggle with outdated processes that drain resources, cause excessive downtime, and squeeze profits. This is why, in today’s evolving market, the key to staying ahead is embracing the principles outlined in “The Competitive Advantage of Automation in Structural Steel Fabrication: Why investing in cutting-edge processing technology is the key to staying ahead in the industry.” Leveraging advanced automation solutions gives fabricators the ability to deliver consistent quality at scale, while minimizing overhead and operational risks.

As Regional Sales Executive at Mac-Tech, I guide businesses through challenging operational bottlenecks and identify targeted solutions that deliver the greatest efficiency gains. My role is more than just selling equipment; it’s about serving as your strategic partner to ensure you plug into the right technology—right when you need it. Through automated beam coping, drilling, and advanced software integration, I help companies eliminate wasteful steps, optimize resource allocation, and significantly improve ROI.

Securing a Competitive Edge: How Automation Is Reshaping Structural Steel Fabrication

Automation isn’t just about replacing manual labor; it’s about creating a more agile, resilient operation that can handle complex projects under tight deadlines. Factors like labor shortages, rising material costs, and increasing project complexity are forcing fabricators to rethink traditional methods. When you incorporate robotics and computerized control systems into the structural steel fabrication line, you can reduce material handling, cut cycle times, and dramatically improve your bottom line.

In my experience, automation delivers the most value when tailored to a shop’s unique workflow. A robotic beam coping solution, for instance, can automatically process structural beams with minimal human intervention, slashing production times and boosting throughput. In an industry where the slightest delay can derail entire projects, the ability to precisely schedule and execute tasks further underscores the transformative power of automation.

A Trusted Advisor’s Approach: Tailoring High-Impact Solutions for Your Business

I understand that automation investments can be daunting, especially when it comes to balancing costs, employee training, and integration requirements. That’s why I put a premium on strategic consultation. I begin by assessing your current workflows, identifying bottlenecks, and quantifying inefficiencies. From there, I propose targeted improvements that not only address immediate needs but also set you up for scalable growth.

Acting as a trusted advisor means more than just recommending equipment. It involves a comprehensive approach that includes layout optimization, software integration, and ongoing support. By bringing together equipment specialists, software engineers, and training experts, Mac-Tech ensures you have a cohesive team aligned with your business objectives. My ultimate goal is to help you implement automated solutions that can quickly adapt to changing market demands and evolving organizational goals—without breaking your budget.

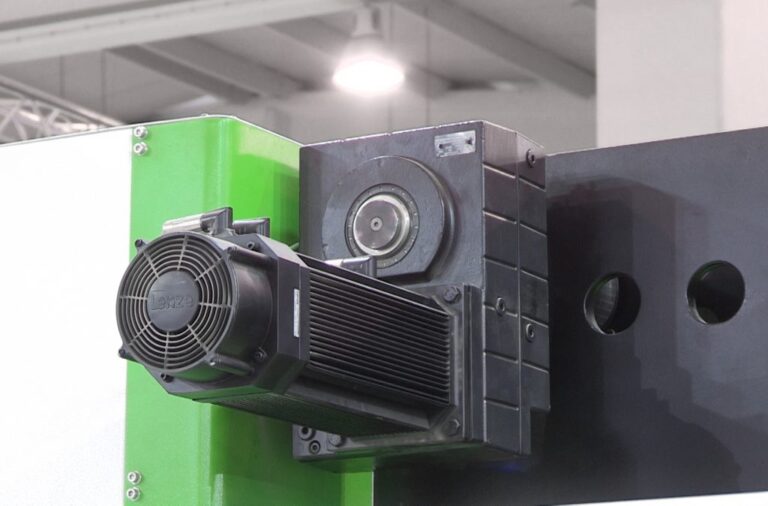

3ADM 1200 Beam

AFD Plate Drilling Machines

Achieving Scalable ROI with Beam Coping, Beam Drilling, and Prodevco Technology

Beam coping and drilling are notorious productivity bottlenecks when performed manually or on outdated machinery. Prodevco technology streamlines these processes by automatically measuring, cutting, and drilling beams with extreme precision. By eliminating operator errors and repetitive manual labor, you not only cut down on scrap but also reallocate skilled labor to higher-value tasks—bolstering innovation and growth.

Return on investment is more than a mere calculation of machine costs versus labor savings. It’s about building a foundation for sustained profitability. Automated beam coping and drilling solutions, coupled with Prodevco’s advanced software, help you lower operational risks, accelerate project timelines, and handle higher volumes with consistent quality. Over time, this leads to more predictable budgeting and improved client satisfaction, setting you apart in a competitive market.

Frequently Asked Questions

How can automation improve my profitability if I already have skilled operators?

Automation complements skilled operators by eliminating repetitive tasks, reducing errors, and maximizing throughput. Your workforce can then focus on higher-level responsibilities such as quality control and workflow optimization.

Is it difficult to integrate robotic beam coping into existing operations?

The key lies in careful planning and consultation. I work closely with your team to ensure seamless integration of hardware and software, minimizing disruption and getting your line operational as quickly as possible.

Does automation mean I’ll have to replace my entire production line?

Not necessarily. Often, strategic retrofits—like adding a beam coping or drilling station—boost performance without requiring a complete overhaul. We tailor solutions to meet your current and future needs.

What kind of ROI can I expect, and how soon?

Most clients see a substantial improvement in efficiency and accuracy within the first few months. The exact ROI timeline depends on project volume, but many experience payback periods that justify the investment quite rapidly.

How do I handle training and maintenance for new automated systems?

Mac-Tech offers thorough training programs and ongoing support to ensure your staff is well-versed in operating and maintaining the equipment. Regular maintenance schedules are designed to keep downtime at a minimum.

Will automated solutions drive away my skilled workforce?

On the contrary, automation frees up employees to excel in roles that require critical thinking and creativity. This shift can enhance job satisfaction and foster a more engaged workforce.

Can smaller shops benefit from automated solutions?

Absolutely. Automation can be scaled to match your shop’s size and project volume, ensuring you gain efficiencies without taking on more than you can handle.

I’ve witnessed firsthand how adopting cutting-edge automation strategies can revolutionize operations and spur significant growth. By eliminating manual inefficiencies, reducing waste, and enhancing throughput, you can achieve an unmatched competitive advantage. Whether you need a fully automated beam processing line or a phased approach to scaling up, I’m here to customize a solution that maximizes your ROI and positions your business for sustained success.

Let’s start the conversation. I invite you to connect with me, Dave Graf, at Mac-Tech, and discover how smart automation can put you ahead of the curve in the structural steel fabrication sector.

Get Weekly Mac-Tech News & Updates