At Mac-Tech, I’ve had the privilege of working with a diverse range of clients, particularly Boss Laser users. Over the years, I’ve discovered that building strong partnerships is not just about selling equipment; it’s about understanding the unique needs of each customer and providing them with solutions that enhance their operations. My journey in this field has been driven by a commitment to helping clients improve efficiencies and achieve their goals, leveraging my expertise in flat and tube lasers, beam line robotic coping, press brakes, and tube bending.

Building Trust with Boss Laser Users

Establishing trust with Boss Laser users begins with genuine communication. I make it a point to listen actively to their concerns and objectives, ensuring that I fully understand their business environment. This open dialogue allows me to build a foundation of trust, where clients feel comfortable sharing their challenges and aspirations.

Once trust is established, I focus on demonstrating my expertise. I provide insights into the latest advancements in laser technology and how these can be applied to improve their operations. By sharing real-world examples and case studies, I help clients visualize the potential benefits and build confidence in the solutions I propose.

Finally, maintaining transparency throughout the sales and implementation process is crucial. I ensure that clients are informed at every stage, from initial discussions to post-purchase support. This transparency not only strengthens our partnership but also reassures clients that they are making informed decisions.

Understanding Customer Needs and Challenges

Every client has unique needs and challenges, and understanding these is key to providing effective solutions. I begin by conducting a thorough assessment of their current processes, identifying areas where efficiencies can be improved. This involves asking the right questions and digging deep into their operational workflows.

By understanding the specific challenges that Boss Laser users face, I can tailor my recommendations to address their pain points. Whether it’s optimizing cutting speeds, improving precision, or reducing downtime, I work closely with clients to identify the most impactful areas for improvement.

Moreover, I recognize that challenges evolve over time. Regular follow-ups and check-ins allow me to stay updated on any new issues or changes in their operations. This proactive approach ensures that I am always ready to assist with timely solutions, reinforcing my commitment to their success.

Crafting Tailored Solutions with Fiber Laser

Crafting tailored solutions involves leveraging the capabilities of fiber laser technology to meet the distinct needs of each client. I take the time to explain how fiber lasers can enhance their production processes, from cutting and engraving to welding and marking.

By customizing solutions, I ensure that each client receives the maximum benefit from their investment. This might involve recommending specific laser models, adjusting power settings, or integrating additional equipment like press brakes or tube benders to complement their setup.

I also provide comprehensive training and support to ensure that clients can fully utilize their fiber laser systems. This hands-on approach empowers them to operate efficiently and confidently, maximizing productivity and minimizing the learning curve.

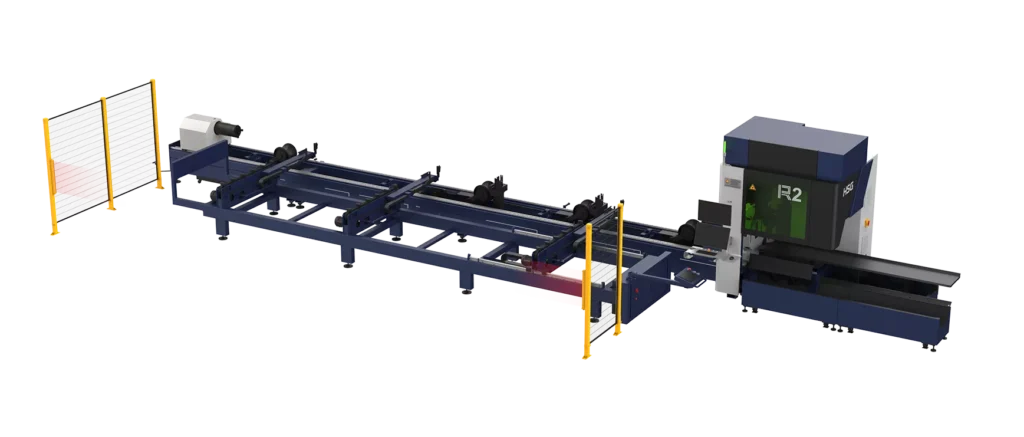

HSG TS2 HIGH SPEED TUBE FIBER LASER CUTTING MACHINE

Ensuring Satisfaction Through Continuous Support

Customer satisfaction is at the heart of my approach, and continuous support plays a vital role in achieving it. After the initial sale and implementation, I remain available to address any questions or concerns that may arise. This ongoing support is crucial for maintaining the performance and longevity of their equipment.

I offer regular maintenance checks and updates to ensure that the systems are running at optimal levels. This proactive maintenance helps prevent potential issues and minimizes downtime, allowing clients to focus on their core business activities.

Furthermore, I encourage feedback from clients to continually refine and improve my services. By listening to their experiences and suggestions, I can adapt my approach to better meet their evolving needs, ensuring long-term satisfaction and success.

FAQ

What should I consider when choosing a laser system?

It’s important to evaluate your specific needs, such as material type, thickness, and production volume. I’ll work with you to assess these factors and recommend the best solution.

How can I improve the efficiency of my current laser setup?

We can conduct a thorough review of your current processes and identify areas for optimization, such as adjusting settings or integrating additional equipment.

What kind of support can I expect after purchasing a laser system?

I provide continuous support, including maintenance, training, and updates, to ensure your system operates efficiently and effectively.

How do fiber lasers compare to other types of lasers?

Fiber lasers offer superior precision, speed, and energy efficiency, making them ideal for a wide range of applications. I’ll help you understand these benefits in the context of your operations.

Can you assist with integrating new laser systems into existing workflows?

Absolutely. I’ll work closely with your team to ensure a seamless integration, minimizing disruptions and maximizing productivity.

What are the benefits of regular maintenance for laser systems?

Regular maintenance helps prevent unexpected issues, extends the lifespan of your equipment, and ensures consistent performance.

Building strong partnerships with Boss Laser users has been incredibly rewarding, and I’m excited to continue supporting clients in optimizing their operations. If you’re interested in exploring how we can enhance your processes, feel free to reach out.

Get Weekly Mac-Tech News & Updates