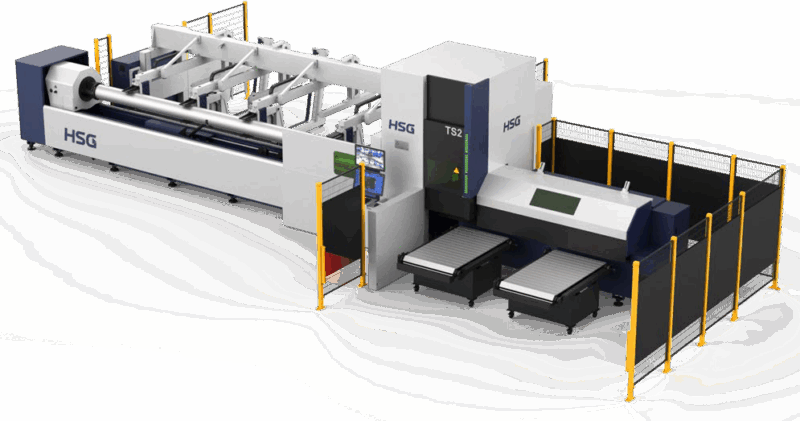

In the ever-evolving world of metal fabrication, efficiency, safety, and cost-effectiveness are paramount. As a Sales & Service Specialist at Mac-Tech, I am committed to helping our clients achieve these goals through innovative solutions and cutting-edge technology. One such solution is the TS2 High-Speed Tube Fiber Laser Cutting Machine. This article delves into the features and benefits of the TS2, highlighting why it stands out as an efficient, safe, and economical choice for your tube cutting needs.

TS2 High-Speed Tube Fiber Laser: Efficient, Safe, and Economical

The TS2 High-Speed Tube Fiber Laser Cutting Machine is designed to revolutionize the way you approach tube cutting. Its high-speed capabilities ensure that you can complete jobs faster without compromising on quality. This efficiency translates to increased productivity, allowing you to take on more projects and meet tight deadlines with ease. The TS2 is not just about speed; it’s about delivering consistent, high-quality cuts that meet the exacting standards of modern fabrication.

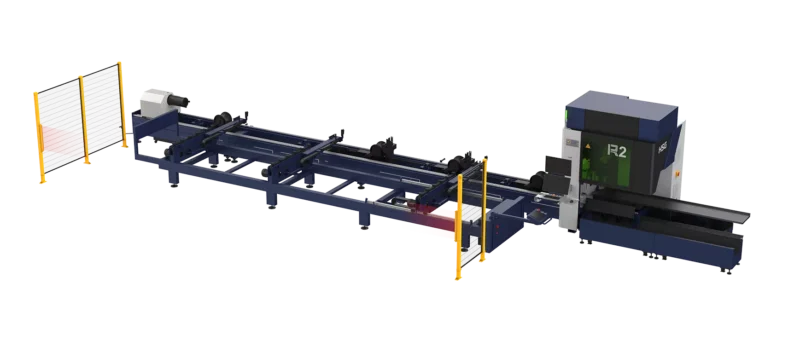

Safety is a critical concern in any manufacturing environment, and the TS2 addresses this with its advanced safety features. The inclusion of safety light curtains ensures that the machine operates within a safe zone, protecting both the operator and the equipment. An alarm system is activated if anything penetrates this zone while the chucks are working at high speed, providing an additional layer of security. This focus on safety means you can operate the TS2 with confidence, knowing that risks are minimized.

Economically, the TS2 offers significant advantages. Its efficient operation reduces energy consumption, lowering your overall operating costs. Additionally, the machine’s ability to handle a wide range of tube sizes and shapes means you can take on diverse projects without the need for multiple machines. This versatility, combined with its low maintenance requirements, makes the TS2 a cost-effective solution for any fabrication shop looking to maximize their return on investment.

Key Features of the TS2 High-Speed Tube Fiber Laser Cutting Machine

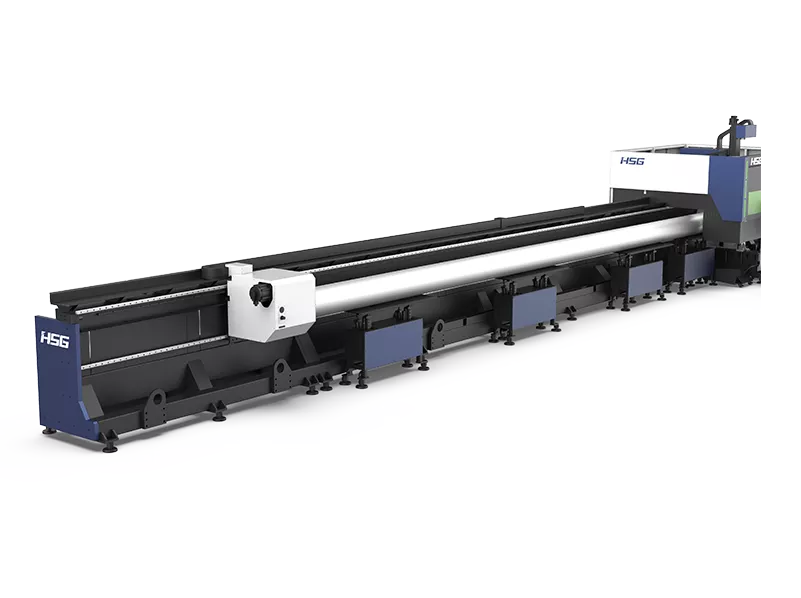

One of the standout features of the TS2 is its rectangular-circle pneumatic chucks. These chucks offer one-key clamping and automatic centering, simplifying the setup process and ensuring that tubes are held securely in place. The large and constant clamping force allows the machine to handle heavy tubes with ease, preventing sagging and deformation. This feature is particularly beneficial for fabricators working with a variety of tube sizes and shapes, as it expands the clamping range to accommodate round tubes up to Φ 240mm and square tubes up to 240mm.

The TS2 is also equipped with a special supporting frame that further enhances its ability to handle heavy tubes. This frame prevents tubes from sagging and deforming during the cutting process, ensuring that each cut is precise and consistent. This level of support is crucial for maintaining the integrity of the material and achieving high-quality results. By preventing deformation, the TS2 helps reduce waste and improve overall efficiency.

Another key feature is the HSG-X Bus Control System, developed by HSG Laser. This bus-based control system is designed to be intelligent and easy to operate, addressing common issues such as difficult operation, low efficiency, and high costs. The HSG-X system streamlines the cutting process, allowing operators to focus on producing high-quality cuts rather than troubleshooting technical issues. This user-friendly interface makes the TS2 accessible to operators of all skill levels, further enhancing its appeal as a versatile and efficient cutting solution.

Ermaksan Tube Laser Selection: 1500W vs 3000W vs 6000W for Maximum ROI and Efficiency

Maximize Growth: Choosing the Right Press Brake and Laser Solutions for Unmatched Efficiency

Transforming Efficiency: How Precision Press Brake Technology Drives Growth and Reduces Waste

Maximizing Profitability: Efficient High-Power Laser Cutting Strategies for Sheet, Plate, and Tube Applications

FAQ

What types of tubes can the TS2 handle?

The TS2 can handle round tubes up to Φ 240mm and square tubes up to 240mm, making it versatile for various projects.

How does the safety light curtain work?

The safety light curtain activates an alarm if anything penetrates the safe zone while the chucks are operating at high speed, ensuring the safety of both the operator and the machine.

What is the benefit of the HSG-X Bus Control System?

The HSG-X Bus Control System simplifies operation, increases efficiency, and reduces costs by providing an intelligent and user-friendly interface.

Can the TS2 prevent tube deformation?

Yes, the TS2 features a special supporting frame that prevents tubes from sagging and deforming during the cutting process.

Is the TS2 economical to operate?

Absolutely. The TS2’s efficient operation reduces energy consumption and its versatility eliminates the need for multiple machines, making it a cost-effective solution.

How does the rectangular-circle pneumatic chuck system work?

The system offers one-key clamping and automatic centering, providing a large and constant clamping force to securely hold heavy tubes.

What makes the TS2 a high-speed machine?

The TS2 is designed for rapid cutting without compromising quality, allowing for faster job completion and increased productivity.

The TS2 High-Speed Tube Fiber Laser Cutting Machine is a game-changer for any fabrication shop looking to enhance efficiency, safety, and cost-effectiveness. With its advanced features and user-friendly design, the TS2 is an investment that promises significant returns. If you’re interested in learning more about how the TS2 can benefit your operations, feel free to reach out to me at dave@mac-tech.com. Let’s discuss your needs and find the perfect solution for your business.

Get Weekly Mac-Tech News & Updates