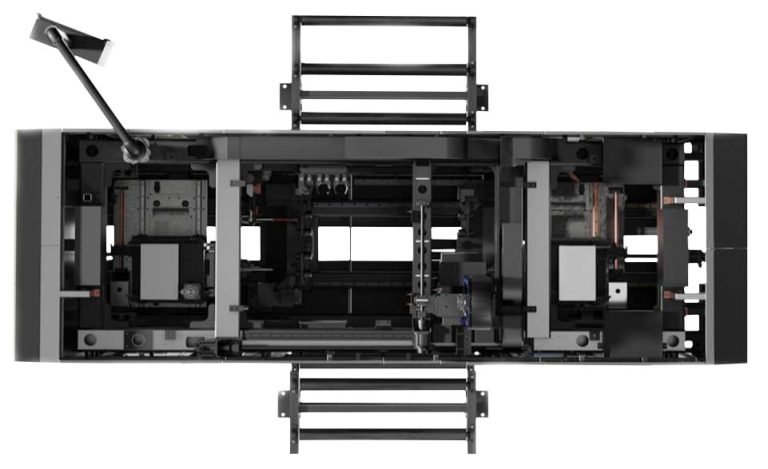

**Overview: Maximizing Efficiency and ROI: How Akyapak’s 3 ADM Drilling Machines Tackle Material Inconsistencies in Structural Steel Processing** In the competitive landscape of structural steel processing, where precision and efficiency are paramount, Dave Graf, Regional Sales Executive at Mac-Tech, sheds light on a transformative solution: Akyapak’s 3 ADM Drilling Machines. This article delves into how these advanced machines address the pervasive issue of material inconsistencies, ultimately driving significant improvements in operational efficiency and return on investment (ROI) for industries such as oil & gas, bridge construction, shipbuilding, and high-rise development. For decision-makers in these sectors, the stakes are high. Material inconsistencies can lead to costly delays, rework, and compromised structural integrity. Graf articulates a compelling value proposition: by integrating Akyapak’s cutting-edge technology, companies can not only streamline their processes but also enhance product quality and reliability, positioning themselves ahead of the competition. As the single point of contact for structural steel processing solutions, Graf emphasizes his commitment to understanding the unique challenges faced by industry leaders. He invites executives to consider a strategic question: Are you leveraging the latest innovations to mitigate risks and maximize your operational potential? This article is not just a discussion of machinery; it’s a call to action for C-suite leaders to rethink their approach to structural steel processing. By exploring the capabilities of Akyapak’s 3 ADM Drilling Machines, Graf provides insights that could redefine efficiency and profitability in your operations. Don’t miss the opportunity to elevate your business—read on to discover how you can turn material inconsistencies into a competitive advantage.