A common issue in fabrication shops is a misaligned saw blade that disrupts production and leads to costly downtime. At Mac-Tech, I ensure that fabrication teams remain operational by coordinating reliable service and accurate part identification. By swiftly addressing such issues, I help maintain seamless operations and prevent extended disruptions.

Understanding Feed Roller and Chain Wear in Hydmech Saws

Causes of Wear:

Feed roller slippage and chain wear in Hydmech saws typically result from continuous use and lack of timely maintenance. These components undergo significant stress, leading to uneven feeding or skipped cycles.

Typical affected parts and fixes:

- Feed Rollers: Worn rollers may not grip materials effectively, causing slippage.

- Chains: Stretched or damaged chains can lead to misalignment and skipped cycles.

Solution:

Replacing worn feed rollers and chains restores consistent throughput, ensuring smooth operation and reducing the risk of further damage.

Preventive Maintenance to Extend Machine Life

Prevention strategies I apply:

- Regular Inspections: Schedule monthly checks on feed rollers and chains to catch early signs of wear.

- Lubrication: Keep chains and rollers well-lubricated to minimize friction and wear.

- Calibration: Regularly calibrate the saw to ensure alignment and optimal performance.

Implementing these strategies significantly extends the lifespan of your equipment and reduces unexpected failures.

HYDMECH V-18-45

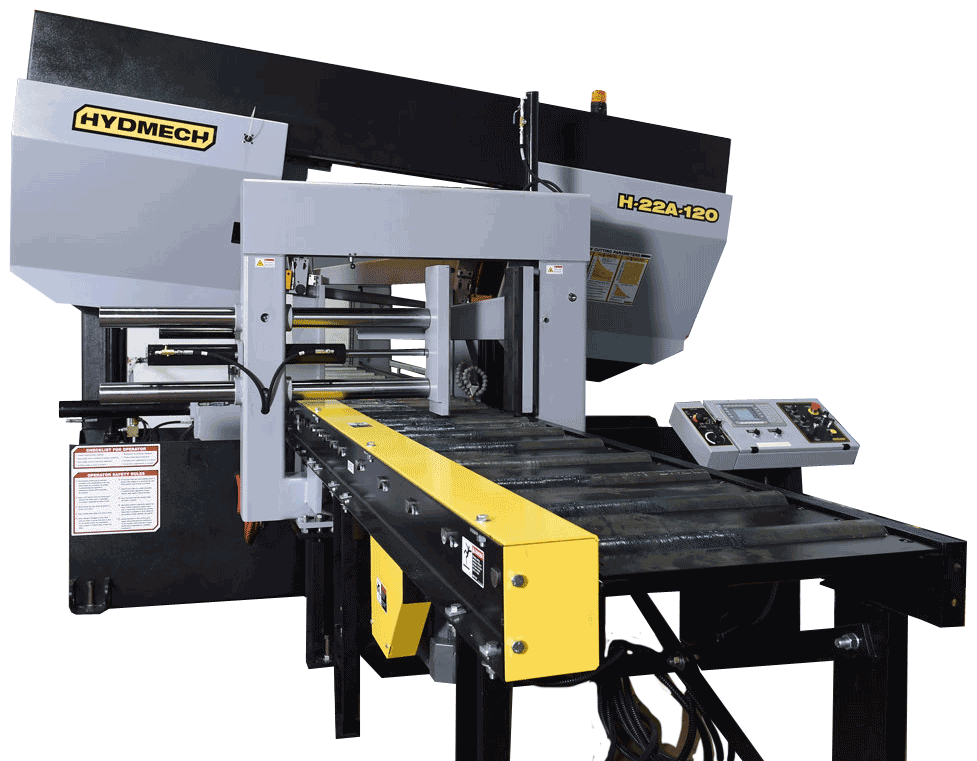

HYDMECH H-22A-120

Expert Parts Sourcing and Service Coordination with Nicole Salato

As the Service & Parts Lead at Mac-Tech, I ensure that all parts sourced are OEM-compliant, maintaining the integrity and performance of your Hydmech saws. My role involves:

- Accurate Part Identification: Utilizing detailed knowledge of machinery to identify the correct parts quickly.

- Service Coordination: Organizing timely service visits to minimize disruption and ensure seamless operations.

My focus is on providing precise solutions that keep your machinery running at peak efficiency.

Minimizing Downtime with Quick Support and Solutions

Response coordination:

- Swift Communication: Immediate response to service requests to assess issues quickly.

- Planned Maintenance: Scheduling regular maintenance to prevent unexpected breakdowns.

By prioritizing quick support and effective solutions, I help fabrication teams reduce downtime and maintain productivity.

FAQ

How often should press brakes be serviced?

Press brakes should receive a hydraulic inspection and oil change every six months or 1,000 operating hours.

How can I tell if my laser needs optics replacement?

Watch for inconsistent cutting speed, wider kerf, or visible lens haze.

Does Mac-Tech provide parts for older machines?

Yes. Nicole verifies compatibility and supports service for both current and legacy models.

For service coordination, preventive maintenance scheduling, or OEM parts support, feel free to contact me directly at Mac-Tech.

Get Weekly Mac-Tech News & Updates