Unlocking the Power of Data Analytics: Elevate Your Metal Fabrication with Modern Equipment Solutions

As a Sales Specialist at Mac-Tech, I’ve had the privilege of helping countless businesses transition from outdated machinery to cutting-edge equipment that not only boosts efficiency but also significantly enhances profitability. The landscape of metal fabrication is rapidly evolving, and data analytics plays a pivotal role in this transformation. By leveraging data insights, companies can make informed decisions about their equipment choices, ensuring they remain competitive in a challenging market. Our trade-in process allows businesses to exchange older machines for advanced models at unprecedented prices, all while enjoying flexible financing options that make the upgrade seamless and cost-effective.

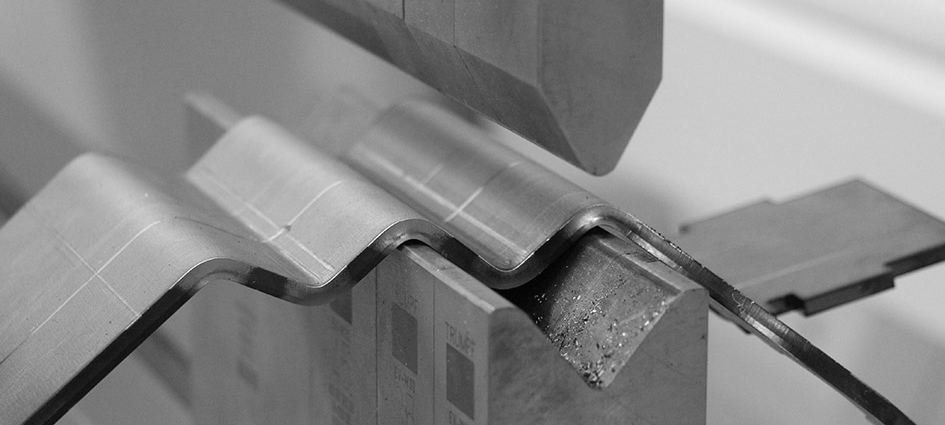

In today’s market, the cost of equipment is lower than ever, and the features available in modern machines are nothing short of revolutionary. With the right data analytics tools, you can pinpoint inefficiencies in your current operations and identify the specific upgrades that will yield the highest return on investment. Whether it’s improved automation, faster production speeds, or enhanced precision, the benefits of upgrading are clear. At Mac-Tech, we empower our clients to embrace these advancements, ensuring they are equipped with the best tools to meet their production demands.

Trading in outdated machines for advanced models opens up a world of possibilities. Not only do you gain access to state-of-the-art technology, but you also position your business to capitalize on new market opportunities. Our fair trade-in options allow you to maximize the value of your existing equipment, ensuring you make a smart investment in your future. With our expert guidance, you can navigate the complexities of upgrading, from selecting the right machinery to securing financing that fits your budget.

Transforming Fabrication Efficiency: The Strategic Role of Data Analytics in Upgrading Equipment

Data analytics is a game-changer when it comes to optimizing fabrication workflows. By analyzing operational data, businesses can uncover hidden inefficiencies and identify the best machinery to enhance their processes. This strategic approach not only streamlines production but also reduces waste and lowers operational costs. At Mac-Tech, we understand how critical these insights are and are committed to helping our clients harness the power of data to make informed equipment choices.

When considering a trade-in, several factors can significantly influence the value of your existing machines. The condition of the equipment, its age, and market demand all play a role in determining its worth. We encourage businesses to take a comprehensive inventory of their machinery and utilize our expertise to assess its value accurately. By doing so, you can maximize your investment when upgrading, ensuring that every dollar spent on new equipment is a dollar well invested.

Mac-Tech is here to facilitate the transition from used to new equipment, making the process as smooth as possible. Whether you’re looking to sell used machines or secure financing for your new purchases, our team is ready to assist. We offer a range of financing options tailored to meet the unique needs of each business, ensuring that you have the resources necessary to invest in the future of your fabrication processes.

FAQ Section

How does the trade-in process work?

Our trade-in process is straightforward. Simply contact us with details about your existing equipment, and we’ll evaluate its condition and market value. We’ll then provide you with a fair trade-in offer that can be applied toward your new purchase.

What machines qualify for trade-ins?

We accept machines of various types and conditions. Whether your equipment is operational or requires repairs, we’re interested in helping you maximize its value.

What financing options are available for upgraded equipment?

We offer flexible financing solutions tailored to your business needs, including lease options and installment plans that make it easier to invest in new technology without breaking the bank.

How do newer machines improve efficiency and production?

Modern machines come equipped with advanced features such as automation, enhanced precision, and faster processing speeds, all of which contribute to increased efficiency and higher production rates.

As we look toward the future of metal fabrication, now is the perfect time to take advantage of the best trade-in and financing deals available. At Mac-Tech, we are dedicated to making your upgrade process seamless and cost-effective. Don’t let outdated equipment hold you back; let us help you elevate your fabrication capabilities today!

Get Weekly Mac-Tech News & Updates