As Service & Parts Lead at Mac-Tech, I understand how critical it is for our customers to keep their machines running at peak performance. Every day, I help fabricators and manufacturers resolve technical issues, source the right parts, and maintain their equipment—especially when it comes to saws and press brakes that have been in service for years. One of the most common requests I receive is for user manuals, particularly for older Hydmech saws. Having the right documentation is essential for safe operation, accurate troubleshooting, and efficient maintenance.

Why Having the Right User Manual Matters for Your Hydmech Saw

A user manual is more than just a reference guide—it’s the foundation for safe and effective machine operation. The correct manual provides detailed information on hydraulic systems, CNC controls, wiring diagrams, and maintenance schedules. For saws over 10 years old, this documentation is crucial. It ensures that operators follow the right procedures, avoid costly mistakes, and extend the lifespan of their equipment. In my experience, preventative maintenance is only as good as the information you have, and a reliable manual is the first step in that process.

Common Challenges When Searching for Older Manuals

Locating a manual for a saw that’s been in service for a decade or more can be surprisingly challenging. Manufacturers often update models, and documentation may change or become archived. Serial numbers and model designations can wear off or be replaced during repairs. Sometimes, previous owners may not have passed along paperwork, or digital copies may be missing. These challenges can slow down troubleshooting, delay parts sourcing, and even risk improper repairs if the wrong procedures are followed.

Proven Strategies to Locate Manuals for Saws Over 10 Years Old

Drawing from years of service experience, I recommend these proven strategies:

- Gather All Machine Details: Start with the serial number, model designation, and any production tags on the saw. Even partial information can help narrow down the search.

- Check with the Manufacturer: Hydmech maintains an archive of older manuals. Their technical support team can often provide digital copies if you supply accurate machine details.

- Contact Your Service Provider: At Mac-Tech, we maintain a robust library of manuals and technical documents for many brands and models, including legacy equipment. We’re often able to match machines to their correct manuals faster than general web searches.

- Network with Industry Peers: Sometimes, other shops or service professionals have retained copies of older manuals. Online forums and professional groups can be valuable resources.

- Inspect for Updates or Retrofits: If your saw has been updated with new controls or components, you may need supplemental documentation. Always note any modifications when requesting a manual.

HYDMECH CSNC-65

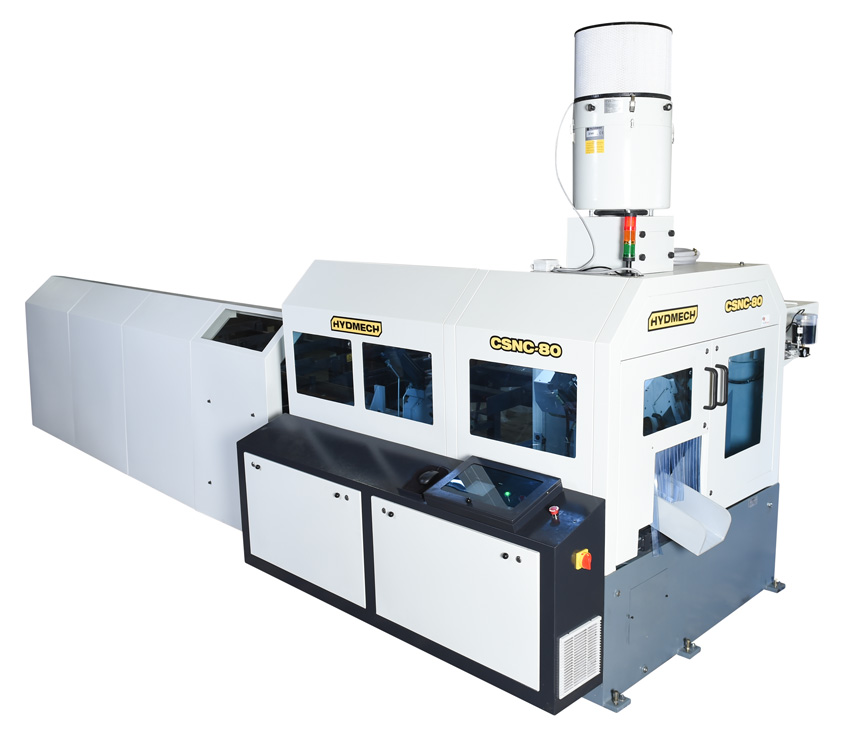

HYDMECH CSNC-80

When to Contact an Expert for Parts and Service Support

If you’re unable to locate the right manual, or if you encounter issues with hydraulic systems, CNC controls, or electrical components, it’s time to reach out to an expert. At Mac-Tech, we provide fast turnaround on parts sourcing and can coordinate onsite or remote service. Our team helps customers troubleshoot issues, identify correct replacement parts, and ensure that repairs are completed according to manufacturer specifications. Reliable sourcing and quick problem-solving support are essential for minimizing downtime and keeping your operation running smoothly.

FAQ

How quickly can Mac-Tech source parts for older Hydmech saws?

Lead times vary, but we prioritize fast turnaround and maintain strong supplier relationships. Many common parts can be sourced within a few days, while rare items may take longer. We’ll always provide an estimated timeline up front.

What are the signs that my saw needs professional service?

Unusual noises, inconsistent cutting accuracy, hydraulic leaks, or error codes on the control panel are common indicators. If you notice any of these, it’s best to consult a service expert before attempting further use.

What preventative maintenance should I perform on my saw?

Regularly inspect hydraulic fluid levels, check for leaks, clean filters, and verify blade tension and alignment. Following the manufacturer’s recommended schedule is key to avoiding costly repairs.

What is Mac-Tech’s ordering and response process for service requests?

Once you contact us, we’ll gather your machine details and assess your needs. We coordinate parts sourcing, provide clear timelines, and can schedule onsite or remote service as needed. Communication and transparency are our priorities throughout the process.

Can Mac-Tech help if my saw has been retrofitted or modified?

Absolutely. Please provide details on any upgrades or changes. We’ll help identify the right documentation and parts for your unique setup.

I’m always here to help you keep your equipment running safely and efficiently—whether you need a hard-to-find manual, expert service, or reliable parts sourcing. Don’t hesitate to reach out for service coordination, technical support, or maintenance advice. Your productivity and peace of mind are my top priorities.

Get Weekly Mac-Tech News & Updates