As Service and Parts Lead at Mac-Tech, I help fabrication shops keep critical machines running by pairing reliable service coordination with properly sourced parts. Every day I work with maintenance managers, operators, and owners to plan maintenance windows, prepare the right parts before a technician arrives, and prevent small issues from becoming costly shutdowns.

Why Scheduled Maintenance Beats Emergency Repairs in Fabrication Shops

Unplanned downtime is disruptive and expensive. With scheduled maintenance, we select the timing, stage the parts, and assign the right technician so your press brakes, hydraulic systems, and CNC controls get attention before a failure occurs. That control lowers risk, protects safety, and keeps quality consistent.

Press brakes tell the story early. Inconsistent bend angles, creeping offsets, and backgauge repeatability issues usually trace back to lubrication gaps, worn tooling seats, or encoder drift. Hydraulics suffer from heat, contamination, and seal wear. Oil that is overdue for replacement loses lubricity and creates varnish that sticks valves. CNC controls give early warnings through alarms, intermittent I/O faults, or battery messages. Scheduled checks catch those signals in time.

When we plan maintenance, we also clean cabinets, change filters on a schedule, verify backups of CNC parameters, and recalibrate as needed. The result is predictable output and fewer surprises.

DELEM DA-69S

Delem DA-69S Press Brake Control

Advanced 3D Graphical Control for High-Precision Bending

Mac-Tech proudly offers the Delem…

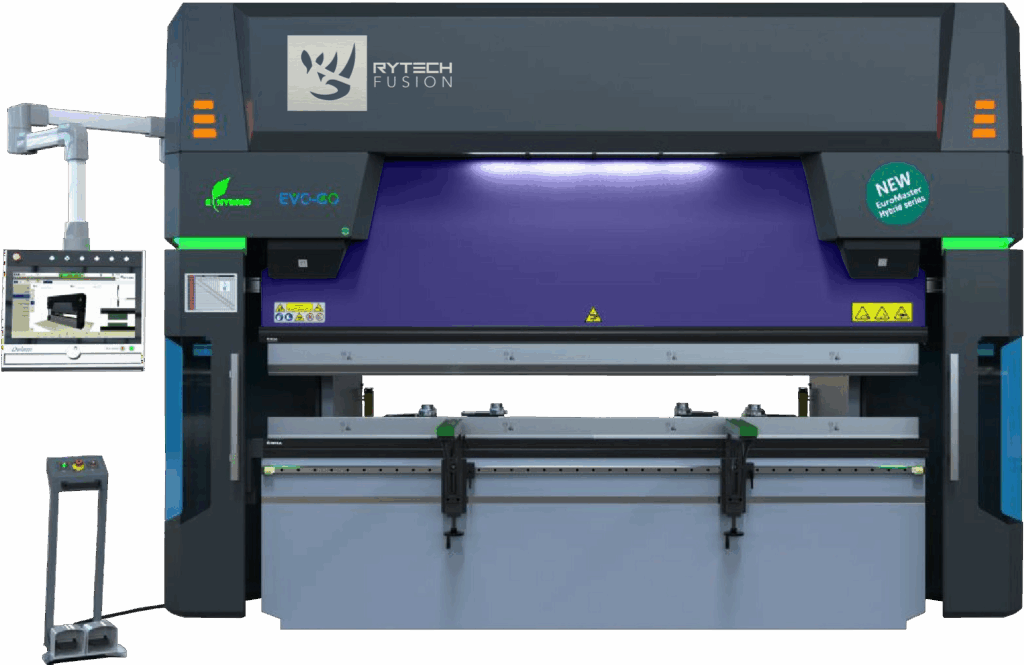

RYTECH FUSION HYBRID PERFORMANCE PRESS BRAKE

RyTech Press Brakes: Engineered for Power, Precision, and Performance

RyTech press brakes deliver exceptional bending performance across a broad spectrum of applications. With a comprehensive…

What I Deliver: Parts Sourcing, Preventative Maintenance Plans, and Service Coordination

Parts sourcing

- I cross reference OEM and equivalent components, confirm drop-in compatibility, and verify part numbers using photos of the nameplate and serial tag. For fast movers like filters, seals, sensors, contactors, hydraulic hoses, and linear guides, I work with vetted suppliers to shorten lead time and hold stock where it makes sense.

- I help you standardize spares across similar machines to reduce inventory and downtime. If a component is obsolete, I identify a tested replacement and confirm fit, electrical ratings, and control integration before shipment.

Preventative maintenance plans

- Press brakes: lubrication of gibs and guides, inspection of backgauge rails and ball screws, check of ram parallelism and crowning, encoder and linear scale cleaning, safety device function checks.

- Hydraulics: oil sampling, filter and breather changes, leak and hose inspections, pump condition and noise trend checks, temperature profiling, tank cleaning when required.

- CNC controls: verified parameter and program backups, battery replacement on schedule, fan and filter cleaning, cabinet dust removal, grounding checks, inspection of connectors and I/O, surge and UPS health checks.

- Practical cadence: daily operator checks, monthly cleaning and filter review, quarterly lubrication and alignment checks, semiannual oil analysis, annual full calibration and safety validation. I tailor this to your duty cycle and environment.

- Service coordination

- I triage symptoms by phone or video, share pre-visit checklists, and stage a spare kit so the first visit solves the problem. I align technician skills with your machine type, coordinate around production, and follow up with a clear summary and next steps. When remote support can resolve an issue, I guide your team safely through it.

Results You Can Expect: Less Downtime, Longer Machine Life, Faster Support

- Reduced unplanned stops through early detection and parts-on-hand planning

- Longer component life from clean oil, correct lubrication, and controlled temperatures

- Better quality and repeatability from calibrated rams, healthy backgauges, and stable CNC controls

- Faster support because I quote quickly, confirm compatibility up front, and ship in-stock items the same day whenever possible

Ready to Act? Schedule a Maintenance Review or Parts Quote with Nicole Salato at Mac-Tech (nicole@mac-tech.com)

If you are not sure where to start, I can review one machine or your full fleet and build a practical plan. Send the machine type, model, serial number, recent symptoms, and photos of the nameplate to nicole@mac-tech.com and I will respond with options and timelines.

FAQ

How fast can you source common parts?

- Italic: In-stock consumables like filters, seals, contactors, and sensors often ship same day. Specialty items such as servo drives, encoders, or custom hoses typically run 2 to 10 business days. Made-to-order assemblies can take several weeks. I will provide a realistic lead time with your quote.*

How do I know my press brake or hydraulic system needs service soon?

- Italic: Watch for angle drift, slower approach speed, hotter hydraulic oil, new noises, backgauge repeatability issues, alarm codes, or battery warnings in the CNC. Any visible leaks or metal fines in filters are immediate flags.*

What are the top preventative maintenance steps that pay off?

- Italic: Keep oil clean and cool, maintain lubrication on guides and screws, replace filters on schedule, clean electrical cabinets, back up CNC parameters, and verify safety devices. A short monthly checklist prevents most surprises.*

What information speeds up a parts quote?

- Italic: Machine type, model, serial number, part description, part number if known, clear photos, and the symptom. For electrical parts, include voltage and connector photos. I use this to confirm compatibility before shipping.*

How quickly can Mac-Tech respond to a service request?

- Italic: I start with same-day triage and scheduling. Availability depends on location and workload, but staging parts before the visit and resolving what we can remotely shortens the overall timeline significantly.*

Can you help with CNC control backups and parameter security?

- Italic: Yes. I coordinate verified backups, battery replacements on a schedule, and safe restore procedures so a control issue does not become a production stop.*

- Do you offer oil analysis guidance for hydraulics?

- Italic: Yes. I can provide sampling kits, interpret results, and set target cleanliness levels based on your components, then plan filtration or fluid changes accordingly.*

Closing message

I am here to make your maintenance straightforward, your parts easy to source, and your support fast and dependable. Email me at nicole@mac-tech.com and I will help you plan service, quote parts, or troubleshoot the issue so your machines keep producing.

Get Weekly Mac-Tech News & Updates