I’m Kyle Bialozynski, a Sales Executive at Mac-Tech, and I spend a lot of my week walking Midwest shop floors, looking at what’s actually slowing production down. A common pain point I see is weld work becoming the bottleneck after parts are already cut and formed, especially when operators are stuck with slow tacking, lots of grinding, and inconsistent fit up from job to job. In the winter, that pain gets louder when absenteeism, cold material handling, and rework start stacking up and your best welders are pulled in five directions. Handheld laser welding can be a strong ROI tool in the right work mix, but only if you plan where it fits, how you train, and where it does not belong.

Confirm the Work Mix and Part Geometry Where Handheld Laser Welding Pays Off

Handheld laser welding pays off fastest on repeatable, medium-gauge fabrication where you want clean seams with minimal postwork, like mild steel and stainless brackets, frames, enclosures, and short to moderate seam lengths. If your jobs have reasonable access to the joint, consistent gaps, and you are doing a lot of tack then weld workflow, a system like LightWELD can reduce grinding and speed up the handoff to finishing. Where it struggles is deep, hard-to-reach joints, large gap conditions, or parts that need heavy deposition like big structural build-up.

Real-world fit check:

- Frequent tacking and repositioning before final weld

- Stainless jobs where finish quality drives labor

- Small to mid-size weldments that move station to station

- Parts with good access and controlled gap

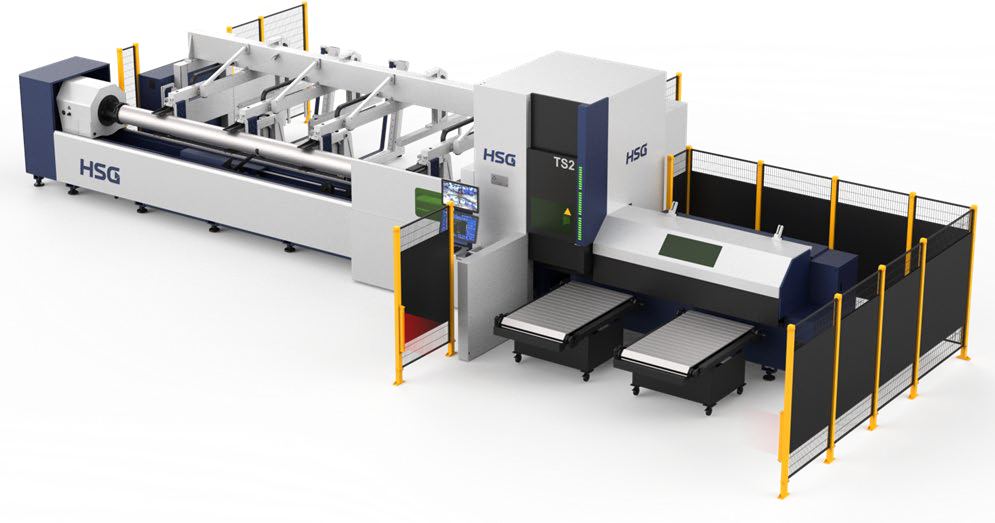

HSG TS2 V2.0 TUBE LASER CUTTING MACHINE

High-Speed Precision for Advanced Tube Processing

The HSG TS2 V2.0 delivers unmatched efficiency and accuracy in tube laser cutting. Equipped with a 6kW…

IPG LIGHTWELD LASER WELDING & CLEANING SYSTEMS

Map Setup Time and Throughput Gains on the Floor From Tack to Finished Seam

Most ROI stories start with reduced touchpoints, not just faster arc time. When handheld laser welding is placed right after forming or fit-up, you can shorten the tack stage, reduce heat distortion, and eliminate a lot of flap disc time before paint or powder. Day to day, that means fewer parts waiting in carts between cutting, bending, and welding, and fewer surprises when a rush job hits the schedule.

From a layout standpoint, think in terms of a compact cell that lives near your fit-up tables, with room for staging and a clean path for material flow. You will still need stable power and good air at a high level, plus fume control and a safe, defined area so your operators are not weaving around traffic to finish a seam.

Reduce Labor Variability With Repeatable Parameters, Fixturing, and Fit Up Discipline

The biggest hidden cost in manual welding is variability between operators and between shifts. Handheld laser welding can tighten that spread, but only if you standardize fit up, clamp parts the same way, and lock in proven parameters by material and thickness. When you pair consistent fixturing with repeatable settings, your good operators stay productive and your newer operators stop creating rework that eats the next job’s slot.

Practical solution:

- Build simple fixtures that control gap and alignment

- Create a short weld recipe sheet by material and gauge

- Use first-article checks before running a batch

- Track rework causes by joint type, not by operator name

This is also where the rest of your fabrication chain matters. If your upstream cut edges are inconsistent, it is hard for any welding process to look good, so I often look at cutting and prep alongside welding workflow, whether you run HSG fiber laser cutting, Hydmech sawing, or Prodevco beam coping for structural work.

Plan Training and Safety Controls That Keep Uptime High and Rework Low

Handheld laser welding is not plug-and-play if you want safe, repeatable output. You need a real training plan, a defined work zone, proper PPE, and clear rules for reflective surfaces, bystanders, and part handling so you do not trade speed for safety incidents or scrap. In most shops, operators can get comfortable with basic operation quickly, but consistent quality comes from coaching on joint prep, torch angle, travel speed, and when to stop and reset fit up.

Safety and uptime basics:

- Dedicated area with barriers or screens and controlled access

- Correct laser-rated PPE and a written checklist

- Fume extraction and housekeeping to keep optics and work area clean

- Simple daily checks so the system is ready at shift start

If you want to keep uptime high, treat it like a production asset, not a pet tool. That means a short daily routine, clean consumables, and a spot in the schedule for quick verification runs, especially after material changes or new operators join the cell.

Know the Process Limits for Materials, Joint Prep, and Handling Without Slowing the Cell

Handheld laser welding is excellent for clean, controlled joints, but it is not a cure for poor prep. Big gaps, heavy mill scale, oily surfaces, and warped parts will slow the cell down because the operator will fight the joint instead of welding it. It is also not the best choice when you need deep fill, thick multi-pass build-up, or when the workpiece is so large that safe handling and positioning becomes the real constraint.

To protect ROI, define what jobs do and do not go to the laser station. If a job requires extensive grinding, large gap bridging, or awkward repositioning with cranes and forklifts, it may be better served by traditional MIG or a dedicated robotic setup, and the laser can stay focused on the high-volume, high-consistency wins that keep scheduling smooth.

Next Steps for a Smarter Shop Upgrade and a Realistic ROI Timeline

Start by timing your current workflow from fit-up through finished seam, including tacking, weld time, grinding, and rework. Then identify two or three high-repeat part families where LightWELD would reduce touchpoints and free up your top welders for the harder work. If your upstream bottleneck is actually cutting quality or part flow, it may make sense to pair welding improvements with process changes around cutting, bending, and staging so you do not simply move the bottleneck.

If you want a practical path, I recommend a short on-site review and a pilot plan with clear success metrics like reduced grinding time, fewer rework tickets, and faster changeovers. You can also browse equipment and workflow add-ons here: https://shop.mac-tech.com/ and I can help you map the welding cell into your existing footprint without disrupting traffic lanes or material staging.

FAQ

Can handheld laser welding replace MIG everywhere?

No. It excels on clean, accessible joints with controlled gaps, but thick fill, deep joints, and poor prep still favor MIG or other processes.

What if our bottleneck is actually plasma cleanup before welding?

That is common. Improving cut quality upstream can make handheld laser welding shine, and many shops evaluate fiber cutting upgrades alongside welding to reduce prep time.

How much footprint do I need for a handheld laser welding area?

Plan for a compact station plus safe boundaries, staging space, and a clear material path. The key is controlling access and keeping it out of main traffic lanes.

How long does operator training typically take?

Operators can learn basic operation quickly, but consistent quality takes structured coaching on fit up, travel speed, and when to stop and reset a joint.

What about winter reliability and maintenance basics?

Keep the area clean and dry, follow a simple daily startup checklist, and stay consistent on consumables and housekeeping. Cold-weather shops do best when they treat it like a scheduled production cell, not a shared tool.

Should we add automation right away?

Only if your part mix is stable and your handling is already disciplined. Many shops win first by standardizing fixturing and flow, then automate once the work is proven repeatable.

Can Mac-Tech help with financing or trade-in planning?

Yes. We can walk through practical options tied to your production needs and timeline, and keep the ROI expectations grounded in your real throughput.

If you want to talk through your specific parts and see where handheld laser welding fits and where it does not, reach me at kyle@mac-tech.com or 414-704-8413, and you can also start here: https://shop.mac-tech.com/.

Get Weekly Mac-Tech News & Updates