In a bustling fabrication shop, a failed sensor or a worn pedal can disrupt operations, leading to costly downtime. As the Service & Parts Lead at Mac-Tech, I ensure that fabrication teams remain operational by coordinating reliable service and accurate part identification and replacement. With my expertise, shops can swiftly address issues like faulty sensors or worn seals, ensuring machines like Ermaksan brakes are always ready for action.

Importance of Replacing Safety Components on Ermaksan Brakes

Common Issues: Faulty sensors and worn pedals are frequent culprits in disabling machine readiness. These components are critical for maintaining compliance and protecting operators.

Affected Parts and Fixes:

- Safety Light Curtains: Replace when they fail to detect obstructions properly.

- Pedal Switches: Swap out when they show signs of wear or unresponsiveness.

Prevention Strategies: Regular inspection and testing of safety components can preempt failures. Establishing a routine check ensures that any deviation is caught early.

Extending Machine Life with Preventive Maintenance

Causes of Wear and Tear: Continuous use leads to component fatigue and eventual failure, particularly in high-demand environments.

Maintenance Steps:

- Conduct visual inspections weekly.

- Perform functional tests monthly.

- Replace worn components promptly.

Benefits: Proactive maintenance extends the lifespan of machinery, reduces unexpected downtimes, and maintains operational efficiency.

ERMAK EVOIII 3760-175

- Ermak EvoIII 3760-175 (193 Ton x 12’)

- 7-Axis: Y1, Y2, X, R, Z1, Z2, X-Prime (+/-3.94”)

- Delem 66Touch CNC Control, 17”

- CNC Motorized Crowning

- Precision Tooling Package

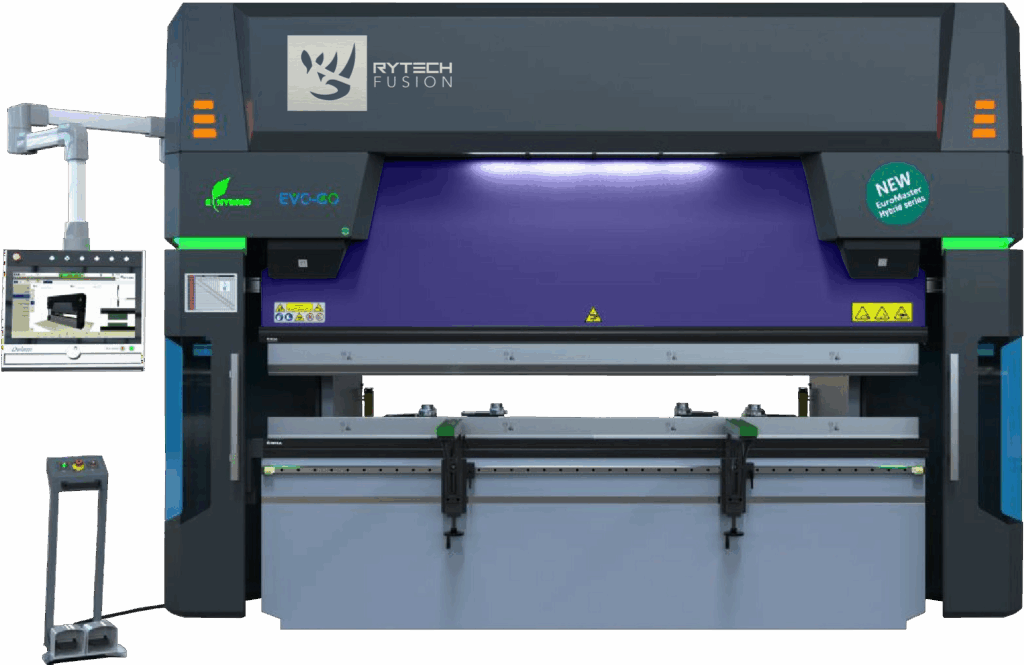

RYTECH FUSION HYBRID PERFORMANCE PRESS BRAKE

RyTech Press Brakes: Engineered for Power, Precision, and Performance

RyTech press brakes deliver exceptional bending performance across a broad spectrum of applications. With a comprehensive…

Expert Parts Sourcing and Service Coordination with Nicole Salato

Role and Responsibilities: As a liaison between suppliers and shops, I ensure rapid response and precise parts matching for Ermaksan brakes.

Coordination Strategies:

- OEM Accuracy: I prioritize original parts to maintain machine integrity.

- Service Scheduling: I coordinate timely service visits to align with production schedules.

Value Points: My approach minimizes downtime and maximizes machine uptime, providing peace of mind to shop managers.

Real-World Solutions for Minimizing Downtime and Maximizing Efficiency

Operational Challenges: Unplanned stoppages due to component failures can halt production lines.

Solutions I Provide:

- Rapid Replacement: Quick swaps of faulty parts to resume operations.

- Efficiency Checks: Routine assessments to identify potential issues before they escalate.

Outcome: These strategies ensure machines run smoothly, reducing interruptions and enhancing productivity.

Contact Nicole Salato for Fast and Reliable Parts Support

For any issues with Ermaksan brakes or other machinery, I am here to provide fast and reliable support. My expertise ensures that you receive the right parts and service coordination to keep your operations running efficiently.

FAQ

How often should press brakes be serviced?

Press brakes should receive a hydraulic inspection and oil change every six months or 1,000 operating hours.

How can I tell if my laser needs optics replacement?

Watch for inconsistent cutting speed, wider kerf, or visible lens haze.

Does Mac-Tech provide parts for older machines?

Yes. Nicole verifies compatibility and supports service for both current and legacy models.

For service coordination, preventive maintenance scheduling, or OEM parts support, feel free to reach out to me directly. Your machinery’s readiness is my priority.

Get Weekly Mac-Tech News & Updates