Enhancing Arizona Builders with Cutting-Edge Equipment Solutions

In the fast-paced world of structural steel fabrication, industries such as oil & gas, bridge building, and shipbuilding face constant challenges in maintaining efficiency and competitiveness. The demand for precision, speed, and cost-effectiveness is at an all-time high. My role as a Regional Sales Executive at Mac-Tech is to be the trusted advisor and single point of contact for our clients, offering turnkey solutions that propel their businesses forward.

Introduction: Empowering Arizona’s Builders

Arizona’s builders are at the forefront of innovation, and empowering them with the right equipment is crucial. As these industries evolve, they need solutions that can adapt to new requirements and enhance productivity. At Mac-Tech, we are committed to connecting these builders with world-class equipment strategies that align with their objectives and help them succeed.

The Role of Automation in Structural Steel Fabrication

Automation is a game-changer in structural steel fabrication. By reducing manual labor and minimizing human error, automated systems streamline operations and boost productivity. Our clients benefit from cutting-edge technologies that not only speed up production but also ensure consistency and precision. As the single point of contact, I coordinate everything from initial consultations to final installations, ensuring seamless integration of these advanced systems.

Streamlining Operations in Oilfield, Bridge, Shipyard, and Tower Projects

In industries like oilfield, bridge, shipyard, and tower construction, the need for streamlined operations is paramount. Automated equipment plays a crucial role in reducing downtime and increasing throughput. Our approach at Mac-Tech includes working closely with suppliers and internal teams to deliver customized solutions that address specific project needs, ultimately enhancing project timelines and reducing costs.

ROBOTIC SOLUTIONS

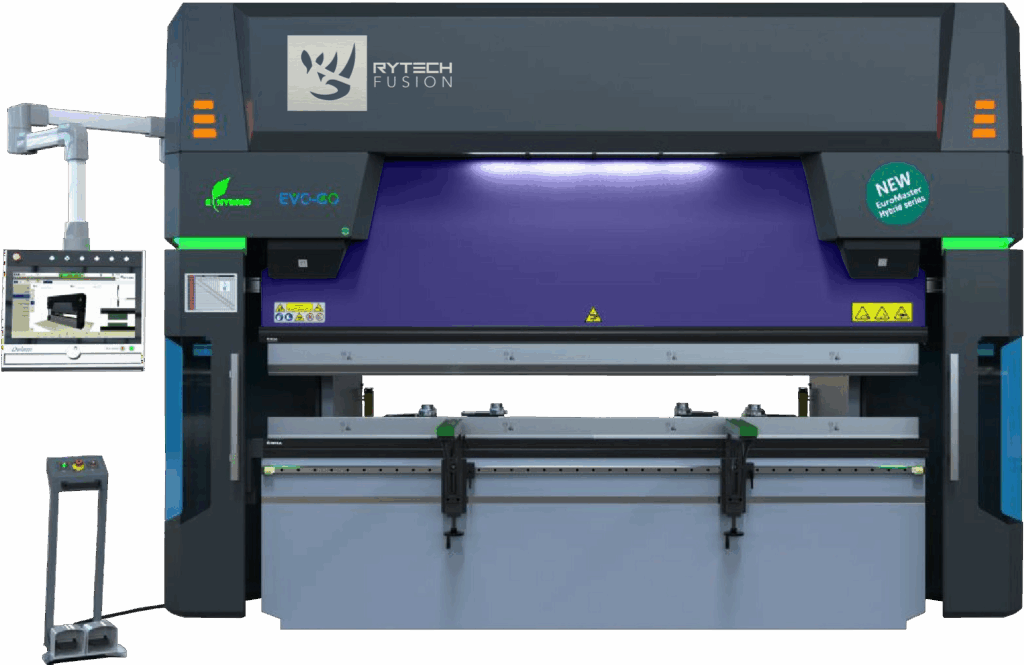

RYTECH FUSION HYBRID PERFORMANCE PRESS BRAKE

RyTech Press Brakes: Engineered for Power, Precision, and Performance

RyTech press brakes deliver exceptional bending performance across a broad spectrum of applications. With a comprehensive…

Maximizing Efficiency with Prodevco, Liberty, and Ermaksan Technologies

Prodevco, Liberty, and Ermaksan technologies offer unparalleled efficiency. These systems are designed to handle complex tasks with ease, from cutting and welding to bending and shaping. By integrating these technologies, we help our clients achieve significant time savings and improved accuracy. I ensure that each piece of equipment is carefully selected and tailored to fit the unique demands of our clients’ operations.

Enhancing ROI with Ercolina, HSG Fiber Lasers, and Akyapak Solutions

Investing in top-tier equipment like Ercolina, HSG Fiber Lasers, and Akyapak solutions translates into a higher return on investment for our clients. These systems are engineered to deliver superior performance and durability, reducing maintenance costs and extending equipment life. My role involves overseeing the entire process, from procurement to installation, ensuring that clients receive the maximum benefit from their investment.

Conclusion: Partnering for Success with Mac-Tech

Partnering with Mac-Tech means more than just buying equipment; it means gaining a strategic ally. Our commitment to delivering exceptional service and support ensures that Arizona’s builders have the resources they need to thrive in a competitive landscape. As your dedicated point of contact, I am here to navigate the complexities of equipment selection and integration, providing solutions that drive success.

FAQ Section

What factors should I consider when choosing equipment?

Consider the specific needs of your project, including speed, precision, and compatibility with existing systems. I can help guide you through the selection process.

How do these machines improve ROI?

They enhance efficiency, reduce labor costs, and minimize downtime, leading to increased productivity and profitability.

What are the lead times for equipment delivery and installation?

Lead times vary, but I coordinate with suppliers to ensure timely delivery and smooth installation, keeping your project on schedule.

Can these systems be integrated with existing equipment?

Yes, many of our solutions are designed for seamless integration. I work with our technical teams to ensure compatibility and efficiency.

How does Mac-Tech support post-installation?

We offer comprehensive support, including training, maintenance, and troubleshooting, to ensure your equipment operates at peak performance.

Get Weekly Mac-Tech News & Updates