As Service & Parts Lead at Mac-Tech, I work every day to ensure our customers’ equipment stays productive and reliable. My team and I coordinate service calls, source parts, and troubleshoot issues for a range of advanced machinery, including Rytech, HSG, and Akyapak systems. Our mission is to minimize downtime and keep your operations running smoothly, no matter how complex your equipment lineup.

Understanding the Challenges of Multi-Machine Service Coordination

Managing multiple machine brands within a single facility presents unique challenges. Each machine type—be it a press brake, hydraulic system, or CNC-controlled fabrication tool—has its own service protocols, parts requirements, and maintenance schedules. Coordinating service calls across Rytech, HSG, and Akyapak equipment means balancing different technical needs, ensuring parts compatibility, and aligning with your production schedules to avoid unnecessary interruptions.

One of the biggest hurdles is communication: clear, timely updates between our service team and your shop floor are essential. We also face logistical challenges in parts availability and technician specialization. That’s why we maintain a robust inventory and a highly trained service staff, ready to address issues across all supported equipment lines.

Key Strategies for Managing Rytech, HSG, and Akyapak Equipment

Success in multi-machine environments starts with preparation. We keep detailed maintenance records for each customer’s equipment, allowing us to anticipate service needs and schedule calls efficiently. Our technicians are cross-trained on the unique features of Rytech, HSG, and Akyapak machines, from hydraulic press brakes to advanced CNC controls. This ensures that, no matter which machine needs attention, we can dispatch the right expert with the right parts.

We also prioritize flexible scheduling and proactive communication. By coordinating service visits for multiple machines at once, we minimize disruption and reduce travel costs. Our customers appreciate having a single point of contact for all their service needs, streamlining the process and building trust.

Maximizing Uptime with Expert Parts Sourcing and Preventative Maintenance

Parts availability is critical in minimizing downtime. We work closely with trusted suppliers to maintain an inventory of high-demand components for all supported brands. When a unique part is needed, we expedite sourcing to keep your machines running. Our experience with press brake maintenance, hydraulic troubleshooting, and CNC diagnostics allows us to identify potential issues before they become costly failures.

Preventative maintenance is the backbone of reliable operations. We help customers develop schedules for inspections, lubrication, and calibration, tailored to the specific requirements of each machine. Regular checkups catch wear and tear early, reducing emergency repairs and extending equipment life.

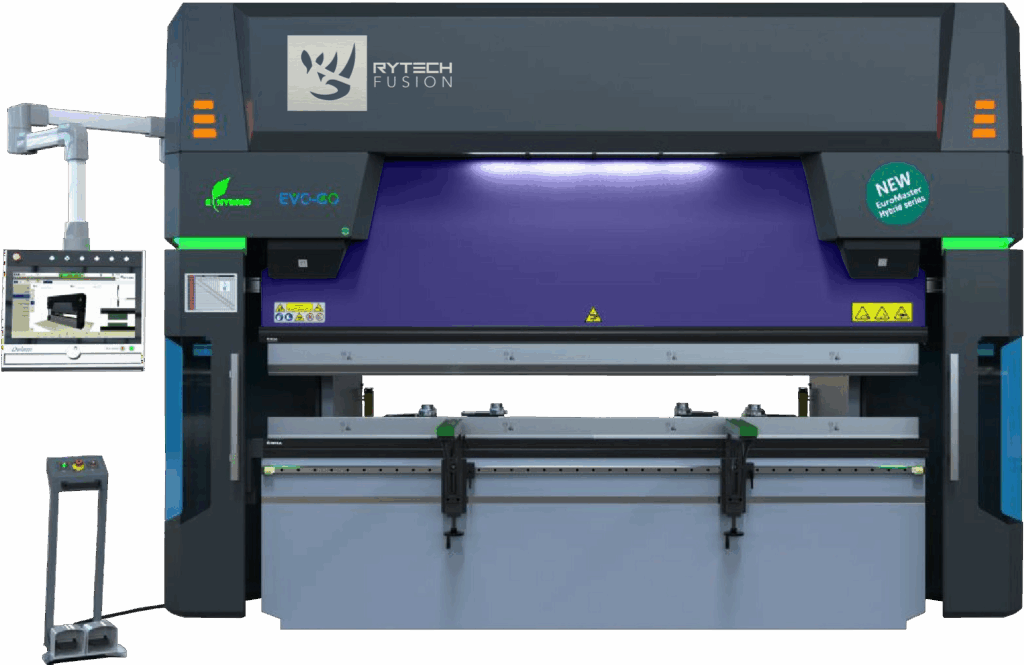

RYTECH FUSION HYBRID PERFORMANCE PRESS BRAKE

RyTech Press Brakes: Engineered for Power, Precision, and Performance

RyTech press brakes deliver exceptional bending performance across a broad spectrum of applications. With a comprehensive…

TANDEM PRESS BRAKE

Contact Nicole Salato for Reliable Service and Support

No matter how complex your equipment mix, Mac-Tech is here to help. I’m committed to supporting your team with responsive service, expert advice, and fast parts fulfillment. Whether you need immediate repairs, preventative maintenance planning, or help sourcing a hard-to-find component, you can count on us to deliver solutions that keep your machines at peak performance.

FAQ

How quickly can you source parts for Rytech, HSG, or Akyapak machines?

Most common parts are available from our inventory or can be sourced within a few days. For specialty items, we leverage our supplier network to expedite delivery and minimize downtime.

What are the signs that my machine needs service?

Look for changes in cycle times, unusual noises, hydraulic leaks, inconsistent bends, or error messages on CNC controls. Early attention to these signs can prevent bigger problems.

What preventative maintenance steps do you recommend?

Regular inspections, lubrication, filter changes, and calibration are essential. We recommend following manufacturer schedules and supplementing with our own checklists tailored to your equipment.

How fast can Mac-Tech respond to a service request?

Our team prioritizes urgent issues and aims to respond within 24 hours. For planned maintenance, we coordinate with your schedule for minimal disruption.

What is the process for ordering parts or scheduling service?

Simply contact me directly or use our online form. I’ll confirm your needs, check part availability, and schedule a technician if required.

If you’re looking for a partner who understands the challenges of managing multiple machines and can deliver the reliable service and parts your operation depends on, I invite you to reach out. My team and I are always here to help you maximize productivity and keep your shop running smoothly.

Get Weekly Mac-Tech News & Updates