I’m Kyle Bialozynski, a Sales Executive at Mac-Tech, and most weeks I’m in Midwest fab shops where the clock starts early and the expectations stay high. One pain point I see over and over is trying to cut thin sheet and thick plate in the same week, then losing hours to setups, nozzle swaps, and plasma cleanup that backs up bending and welding. In winter, that problem gets worse when uptime dips and everyone is fighting frozen air lines, inconsistent cut quality, and schedule changes that make a good machine look like a bad investment. My goal is simple: help you choose a practical HSG fiber laser setup that fits your day-to-day reality, not a perfect-world demo.

Match Laser Source and Cutting Head to Mixed Thickness ROI Targets on the Floor

If you cut both thin and thick, the biggest mistake is buying power for bragging rights instead of matching your actual material mix and tolerance needs. Higher kilowatts can speed thick cutting, but if most of your week is thin gauge, acceleration, parameter stability, and changeover habits often drive ROI more than raw power. I ask what your top 10 materials and thicknesses are, what percent is mild steel vs stainless vs aluminum, and what the real edge quality requirements are for downstream bending and welding.

A practical HSG setup usually comes down to choosing a laser power that covers your thickest work without punishing your thin sheet efficiency. Pair that with a cutting head that handles quick focus changes, stable piercing on thicker plate, and consistent edges on thin material so operators are not babysitting. When that match is right, you stop scheduling your week around the machine’s limitations and start scheduling around customer due dates.

PSB 1050 SHOT BLAST MACHINE

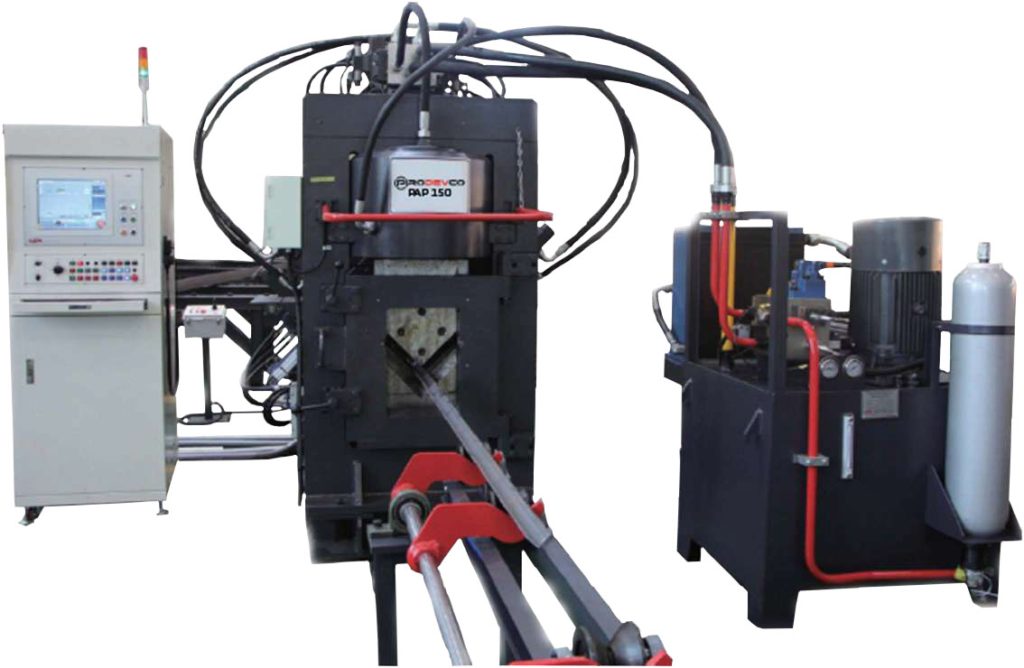

PAP 150 Angle Punching Machine

Reduce Setup Time With Nozzle, Lens, and Gas Changeovers That Operators Actually Use

Mixed thickness shops lose a lot of time to micro-delays: digging for nozzles, checking lenses, changing gas, and re-centering after a crash or tip-up. If the process is annoying, operators will stretch consumable life too far, and you end up with inconsistent edge quality and surprise downtime. That is not an operator problem, it is a system problem.

Real-world problem:

- Nozzle swaps take too long so they get skipped

- Lens checks only happen after cut quality drops

- Gas changes are treated like a special event instead of a standard routine

Practical solution:

- Standardize a small nozzle and lens kit by thickness bands your shop actually runs

- Set up a simple weekly lens and window check as part of the shift start

- Confirm your air supply is dry and stable so assist gas performance is repeatable

On the floor, this means you build a changeover rhythm that people will follow because it is fast and predictable. I also look at high-level utilities with you: stable power, clean dry shop air, and a practical place to stage consumables so the operator is not walking across the building to keep the laser running.

Protect Throughput With Piercing, Edge Quality, and Parameter Libraries That Repeat Shift to Shift

The hidden killer in thick and thin in the same week is piercing and inconsistency between shifts. Thick plate needs stable piercing routines and slag control, while thin sheet needs clean edges without overburn or dross that slows bending and deburring. If you rely on tribal knowledge, your throughput depends on who is working that day.

With HSG, we focus on building and protecting parameter libraries so the machine repeats good results across operators and shifts. The practical win is fewer test cuts, fewer scrap sheets, and less time grinding edges that should have come off the laser ready for the next step. When edge quality is predictable, scheduling becomes easier because downstream departments can trust the cut parts.

Streamline Labor and Material Handling With Load Unload, Sorting, and Part Flow That Fits Your Shop

Even a fast laser will look slow if material handling is manual and chaotic. I see shops where the laser is done cutting, but parts sit on the table because no one has time to unload, sort, or stage for bending. That creates a bottleneck between cutting and the press brake, and it turns your laser into a very expensive parts rack.

The right level of automation can be simple: a load unload system sized to your sheet flow, a clear staging area, and a plan for sorting that matches how you kit jobs for bending and welding. If tube cutting is part of your mix, pairing the laser plan with a Hydmech saw or Prodevco automation can reduce touchpoints upstream and keep the laser fed with the right work at the right time. The result is fewer forklift trips, less part damage, and more consistent labor planning.

Plan Footprint, Uptime, and Service Access So the Cell Runs When Quotes Depend on It

A laser cell is not just the machine footprint, it is also access for service, scrap removal, material staging, and safe operator movement. If you cram it into a corner, you will pay for it later in downtime and frustration. I walk the space with you and talk through where material comes in, where finished parts go, and how you will service the cutting head, change filters, and clean out slats without shutting down half the department.

In Midwest winters, reliability is often tied to basics: dry air, consistent shop temperature around the machine, and a maintenance routine that does not get skipped when you are busy. I also want you thinking about uptime the same way you think about quoting: if the laser goes down, what is your backup plan and how fast can you get support. For reference on practical upgrade paths and options, I often point people to the Mac-Tech storefront as a starting spot for comparing configurations and accessories: https://shop.mac-tech.com/

Next Steps for a Practical HSG Laser Upgrade Built Around Your Mix and Staffing

I start with a simple discovery: your real material mix, average weekly sheet consumption, peak thickness, and what edge quality means for your downstream processes. Then we map it to a practical HSG configuration, the right cutting head setup, and the level of automation your staffing can actually support without creating a new bottleneck. If you are upgrading from plasma, we also talk about how much cleanup time you will realistically eliminate and what that does to bending, welding, and paint flow.

If you want to move quickly, gather a week of cut reports, your top recurring nests, and a list of pain points operators complain about most. From there, I can recommend a right-sized machine, a training plan that sticks, and maintenance habits that protect uptime. If financing or trade-in is part of the plan, we can include that early so the ROI math reflects your real cash flow.

FAQ

Can a fiber laser really replace our plasma if we still cut thicker plate?

Often yes, but it depends on your max thickness, edge quality needs, and how much cleanup you want to eliminate. I look at where plasma still makes sense versus where an HSG fiber laser will reduce grinding and rework.

When does load unload automation make sense?

When your laser is waiting on people more than people are waiting on the laser. Even basic load unload can stabilize staffing and keep cutting consistent across shifts.

How much floor space do I need beyond the machine footprint?

Plan for safe access, service clearance, staging for raw sheets, and finished-part flow. If you can’t remove scrap and service components easily, downtime will rise.

What do power and air requirements look like in plain language?

You need stable electrical service sized for the machine and clean, dry compressed air to keep performance consistent. Most real issues come from wet air, pressure swings, or undersized infrastructure.

How long does training usually take for operators to feel confident?

A good operator can get comfortable quickly when setups are standardized and the parameter library is protected. The goal is repeatable routines, not hero-level troubleshooting.

What maintenance habits help winter reliability the most?

Keep air dry, follow lens and nozzle inspection routines, and keep the area around the machine clean for airflow and service access. Consistency beats occasional deep-clean marathons.

Do you help with financing or trade-ins?

Yes, we can discuss practical paths that match your workload and cash flow, including trade-in considerations where it applies. The key is aligning payment structure with ROI timing.

If you want to talk through your mix and what a practical HSG setup looks like in your shop, reach me at kyle@mac-tech.com or 414-704-8413, and you can also start here: https://shop.mac-tech.com/

Get Weekly Mac-Tech News & Updates