In the ever-evolving world of metal fabrication, efficiency and automation are key drivers of success. The R5-Tube Fiber Laser Cutter stands out as a cutting-edge solution designed to meet these demands. This article delves into the various features and benefits of the R5-Tube Fiber Laser Cutter, highlighting its cost-saving capabilities, automated functionalities, and advanced control systems. As a Sales & Service Specialist at Mac-Tech, I am committed to helping our customers find the best solutions to enhance their productivity and profitability.

Introduction to the Efficient R5-Tube Fiber Laser Cutter

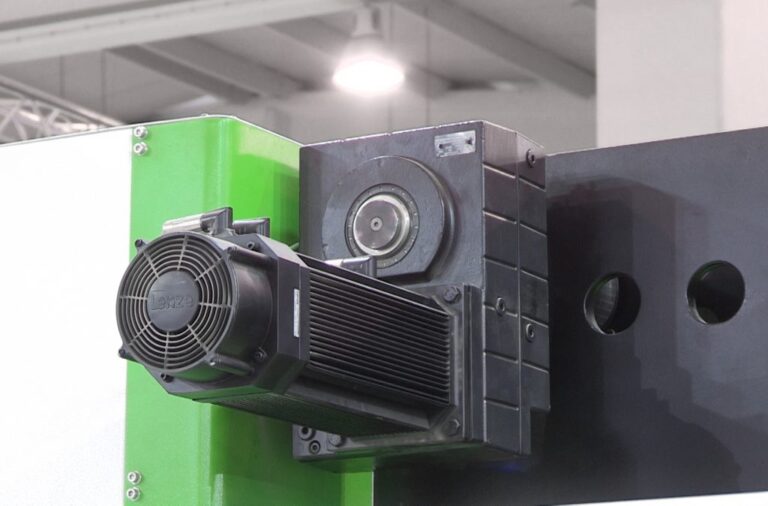

The R5-Tube Fiber Laser Cutter is a state-of-the-art machine engineered to deliver precision and efficiency in tube cutting applications. Its advanced fiber laser technology ensures high-speed cutting with exceptional accuracy, making it an ideal choice for industries requiring intricate and precise cuts. The machine’s robust design and reliable performance make it a valuable asset for any metal fabrication shop.

One of the standout features of the R5-Tube Fiber Laser Cutter is its ability to handle a wide range of materials and thicknesses. Whether you’re working with stainless steel, aluminum, or other metals, this machine can deliver consistent and high-quality results. Its versatility makes it a go-to solution for various applications, from automotive to aerospace industries.

In addition to its cutting capabilities, the R5-Tube Fiber Laser Cutter is designed with user-friendliness in mind. Its intuitive interface and easy-to-operate controls ensure that operators can quickly learn and master the machine, reducing downtime and increasing productivity. This focus on ease of use is a testament to the machine’s design philosophy of combining advanced technology with practical functionality.

Furthermore, the R5-Tube Fiber Laser Cutter is built to last. Its durable construction and high-quality components ensure long-term reliability and minimal maintenance requirements. This durability translates to lower operational costs and a higher return on investment, making it a smart choice for businesses looking to optimize their production processes.

Cost-Saving Benefits of the R5-Tube Fiber Laser Cutter

One of the primary advantages of the R5-Tube Fiber Laser Cutter is its cost-saving potential. By integrating this machine into your production line, you can significantly reduce labor costs. The machine’s high-speed cutting capabilities mean that tasks that previously required multiple operators can now be completed by a single machine, freeing up your workforce for other essential tasks.

Additionally, the precision of the R5-Tube Fiber Laser Cutter minimizes material waste. Its ability to make accurate cuts ensures that you get the most out of your raw materials, reducing the need for costly rework and scrap. This efficiency not only saves money but also contributes to more sustainable manufacturing practices.

The machine’s energy-efficient design is another cost-saving feature. Fiber laser technology consumes less power compared to traditional CO2 lasers, resulting in lower energy bills. This energy efficiency, combined with the machine’s high productivity, means that you can achieve more with less, further enhancing your bottom line.

Moreover, the R5-Tube Fiber Laser Cutter’s low maintenance requirements translate to reduced downtime and lower maintenance costs. Its robust construction and high-quality components ensure that the machine operates smoothly and reliably, minimizing the need for frequent repairs and replacements. This reliability is crucial for maintaining consistent production schedules and meeting customer demands.

Automated Features of the R5-Tube Fiber Laser Cutter

Automation is a key feature of the R5-Tube Fiber Laser Cutter, designed to streamline your production process and enhance efficiency. The machine offers optional automatic loading and unloading devices, which can significantly reduce processing time. By automating these tasks, you can ensure a continuous workflow, minimizing interruptions and maximizing productivity.

The automated loading and unloading devices are particularly beneficial for high-volume production environments. They eliminate the need for manual handling of tubes, reducing the risk of errors and injuries. This automation not only speeds up the production process but also creates a safer working environment for your employees.

In addition to loading and unloading, the R5-Tube Fiber Laser Cutter features advanced automation capabilities for cutting operations. Its intelligent control system can automatically adjust cutting parameters based on the material and thickness, ensuring optimal performance and consistent results. This level of automation reduces the need for manual adjustments, allowing operators to focus on other critical tasks.

Furthermore, the machine’s automation features are designed to be user-friendly. The intuitive interface and easy-to-navigate controls make it simple for operators to set up and manage automated processes. This ease of use ensures that you can quickly integrate the machine into your production line and start reaping the benefits of automation.

Standard 40HQ Container Transport for Cost Efficiency

Transporting large machinery can be a significant expense for any business. The R5-Tube Fiber Laser Cutter addresses this challenge by being designed to fit into a standard 40HQ storage container. This design feature not only simplifies the shipping process but also reduces transportation costs, making it a cost-effective solution for businesses of all sizes.

The use of a standard 40HQ container ensures that the machine can be easily transported by sea, rail, or road. This flexibility in transportation options allows you to choose the most cost-effective and convenient method for your needs. Additionally, the standardized container size means that you can take advantage of bulk shipping rates, further reducing costs.

By shipping the R5-Tube Fiber Laser Cutter in a standard container, you also benefit from reduced handling and storage costs. The container provides a secure and compact way to transport the machine, minimizing the risk of damage during transit. This protection ensures that the machine arrives at your facility in optimal condition, ready for immediate use.

Moreover, the standardized container transport simplifies the logistics of receiving and installing the machine. The container can be easily unloaded and positioned at your facility, reducing the time and effort required for setup. This streamlined process allows you to get the machine up and running quickly, minimizing downtime and maximizing productivity.

Optional Automatic Loading and Unloading Devices

The R5-Tube Fiber Laser Cutter offers optional automatic loading and unloading devices that can further enhance your production efficiency. These devices are designed to handle tubes of various sizes and materials, ensuring seamless integration with your existing workflow. By automating these tasks, you can reduce manual labor and increase throughput.

The automatic loading device is capable of precisely positioning tubes for cutting, ensuring accurate and consistent results. This precision reduces the risk of errors and rework, saving you time and materials. Additionally, the automated process eliminates the need for manual handling, reducing the risk of injuries and improving workplace safety.

The unloading device is equally efficient, quickly and accurately removing cut tubes from the machine. This automation ensures a continuous workflow, minimizing interruptions and maximizing productivity. The unloading device can also be programmed to sort and organize cut tubes, further streamlining your production process.

Integrating these optional devices into your R5-Tube Fiber Laser Cutter setup can significantly reduce labor costs. By automating repetitive and labor-intensive tasks, you can free up your workforce for more value-added activities. This increased efficiency translates to higher productivity and profitability, making the investment in automation well worth it.

Advantages of the HSG-X Bus Control System

The HSG-X Bus Control System is a key feature of the R5-Tube Fiber Laser Cutter, offering advanced control and automation capabilities. Developed by HSG Laser, this bus-based control system is designed to provide intelligent and easy-to-operate service, addressing common challenges in metal fabrication.

One of the primary advantages of the HSG-X Bus Control System is its ability to simplify complex operations. The system’s intuitive interface and user-friendly controls make it easy for operators to set up and manage cutting processes. This ease of use reduces the learning curve and ensures that operators can quickly become proficient with the machine.

The HSG-X Bus Control System also enhances efficiency by automating various aspects of the cutting process. The system can automatically adjust cutting parameters based on the material and thickness, ensuring optimal performance and consistent results. This automation reduces the need for manual adjustments, allowing operators to focus on other critical tasks.

In addition to improving efficiency, the HSG-X Bus Control System helps reduce operational costs. By optimizing cutting parameters and minimizing material waste, the system ensures that you get the most out of your raw materials. This efficiency translates to lower production costs and higher profitability, making the R5-Tube Fiber Laser Cutter a smart investment for your business.

Addressing Operational Challenges with HSG-X Control

The HSG-X Bus Control System is designed to address common operational challenges in metal fabrication, such as difficult operation, low efficiency, and high costs. By providing intelligent and easy-to-operate service, the system helps streamline your production process and enhance overall efficiency.

One of the key challenges in metal fabrication is ensuring consistent and accurate cuts. The HSG-X Bus Control System addresses this challenge by automatically adjusting cutting parameters based on the material and thickness. This automation ensures that each cut is precise and consistent, reducing the need for rework and minimizing material waste.

Another common challenge is managing complex cutting operations. The HSG-X Bus Control System simplifies these operations with its intuitive interface and user-friendly controls. Operators can easily set up and manage cutting processes, reducing the risk of errors and improving overall efficiency. This ease of use ensures that your production line runs smoothly and efficiently.

Finally, the HSG-X Bus Control System helps reduce operational costs by optimizing cutting parameters and minimizing material waste. By ensuring that you get the most out of your raw materials, the system helps lower production costs and increase profitability. This cost-saving potential makes the R5-Tube Fiber Laser Cutter a valuable asset for any metal fabrication business.

HSG TS2 HIGH SPEED TUBE FIBER LASER CUTTING MACHINE

HSG 3015H 12KW

Overview of HSG Fiber Lasers for Tube Cutting Machines

HSG Fiber Lasers are renowned for their advanced technology and exceptional performance in tube cutting applications. The R5-Tube Fiber Laser Cutter is a prime example of HSG’s commitment to innovation and quality, offering a range of features designed to enhance efficiency and productivity.

One of the key advantages of HSG Fiber Lasers is their high-speed cutting capabilities. The advanced fiber laser technology ensures fast and precise cuts, making it ideal for industries requiring intricate and accurate tube cutting. This speed and precision translate to higher productivity and reduced production times.

In addition to their cutting performance, HSG Fiber Lasers are known for their energy efficiency. The fiber laser technology consumes less power compared to traditional CO2 lasers, resulting in lower energy bills and reduced environmental impact. This energy efficiency, combined with the high productivity of HSG Fiber Lasers, makes them a cost-effective and sustainable choice for metal fabrication.

HSG Fiber Lasers are also designed with durability and reliability in mind. The robust construction and high-quality components ensure long-term performance and minimal maintenance requirements. This durability translates to lower operational costs and a higher return on investment, making HSG Fiber Lasers a smart choice for businesses looking to optimize their production processes.

The R5-Tube Fiber Laser Cutter, with its advanced features and cost-saving benefits, is a powerful tool for any metal fabrication business. Its automated functionalities and intelligent control systems ensure high efficiency and productivity, while its durable construction guarantees long-term reliability. If you’re looking to enhance your production process and achieve greater profitability, the R5-Tube Fiber Laser Cutter is an excellent investment. For more information or to discuss your specific needs, feel free to reach out to me.

FAQ

What materials can the R5-Tube Fiber Laser Cutter handle?

The R5-Tube Fiber Laser Cutter is versatile and can handle a wide range of materials, including stainless steel, aluminum, and other metals.

How does the HSG-X Bus Control System improve efficiency?

The HSG-X Bus Control System automates various aspects of the cutting process, such as adjusting cutting parameters based on material and thickness, ensuring optimal performance and consistent results.

What are the benefits of the optional automatic loading and unloading devices?

The optional automatic loading and unloading devices reduce manual labor, increase throughput, and create a safer working environment by eliminating the need for manual handling of tubes.

How does the standard 40HQ container transport reduce costs?

The standard 40HQ container transport simplifies the shipping process, reduces transportation costs, and minimizes handling and storage expenses, ensuring the machine arrives in optimal condition.

What makes HSG Fiber Lasers energy-efficient?

HSG Fiber Lasers consume less power compared to traditional CO2 lasers, resulting in lower energy bills and reduced environmental impact.

Can the R5-Tube Fiber Laser Cutter reduce labor costs?

Yes, the machine’s high-speed cutting capabilities and optional automation features can significantly reduce labor costs by completing tasks that previously required multiple operators.

How durable is the R5-Tube Fiber Laser Cutter?

The R5-Tube Fiber Laser Cutter is built with high-quality components and robust construction, ensuring long-term reliability and minimal maintenance requirements.

Get Weekly Mac-Tech News & Updates