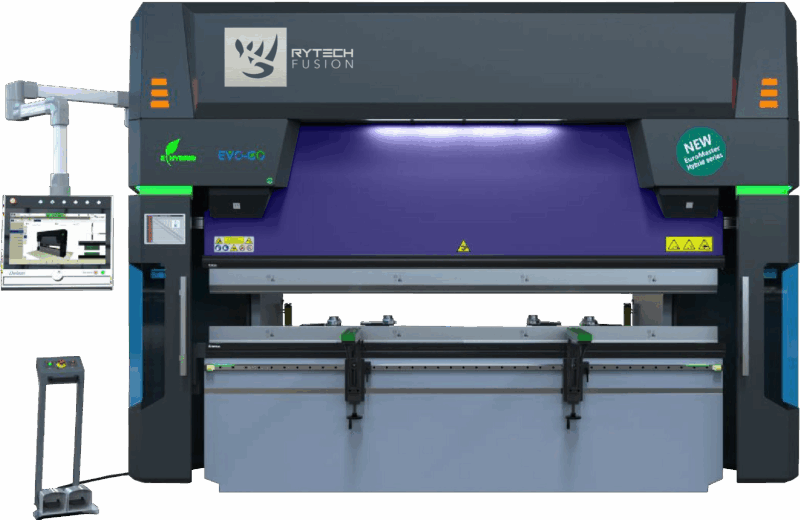

RYTECH FUSION HYBRID PERFORMANCE PRESS BRAKE

RyTech Press Brakes: Engineered for Power, Precision, and Performance

RyTech press brakes deliver exceptional bending performance across a broad spectrum of applications. With a comprehensive range of tonnages and powertrain options—including AMP (Electric), FUSION (Hybrid), and CORE (Premier Hydraulic) systems—RyTech offers tailored solutions to meet the unique needs of every fabricator.

Built using only world-class, proven components—including hydraulics, electrics, safety systems, and controls—each machine is fully engineered and seamlessly integrated to deliver consistent, high-performance bending results.

Backed by Mac-Tech’s industry-leading training and support since 1984, RyTech press brakes combine cutting-edge technology with the trusted service and expertise your operation deserves.

RYTECH FUSION HYBRID PERFORMANCE PRESS BRAKE

Description

Description

WHY the RYTECH FUSION from Mac-Tech?

Innovative Modular Design

• Easily integrates with automation modules for a full-system solution.

• Custom-configurable from basic setups to high-end operations.

Proven Experience

• Backed by 41 years of industry knowledge and over 12,000 machines installed.

• Dedicated R&D focused on delivering competitive bending solutions.

Flexible Bending Solutions

• Standard and custom tooling options.

• Designed with sustainability and social responsibility in mind.

High-Quality Components & Standardized Supply Chain

• Equipped with Tier-1 globally sourced components.

• Stocked and supported across the U.S.

• 3-Year Parts Warranty for peace of mind.

Dedicated After-Sales Service

• Backed by Mac-Tech’s 10-man field service team.

• Local spare parts inventory in Milwaukee, WI.

Specifications

Specifications

TECHNICAL SPECIFICATIONS

| Model | RYTEC FUSION B32.135 |

|---|---|

| Bending Force | 150 Tons |

| Bending Length | 126” |

| Distance Between Columns | 106.2” |

| Stroke | 11.8” |

| Daylight | 22.8” |

| Throat Depth | 17.7” |

| Table Width | 3.54” |

| Table Height | 37.4” |

| Positioning Accuracy | ±0.00019” |

| Rapid Speed | 519.7 IPM |

| Work Speed | 35.4 IPM |

| Return Speed | 472 IPM |

| X-Axis Travel | 31.5” |

| R-Axis Travel | 9.8” |

| Z-Axis Travel | 100.4” |

| Hydraulic Pressure | 275 Bar |

| Servo Motor Power | 2 x 5.7 kW |

| Temperature Range | 0°C to +40°C |

| Dimensions (LxWxH) | 5150 x 2000 x 3050 mm |

| Weight | 25,960 kg |

| Power Supply | 220V–480V, 3-phase, 50/60Hz |

MACHINE CONFIGURATION

| Component | Details |

|---|---|

| CNC Control | DELEM DA60 Series (Netherlands) |

| Electrical | SIEMENS/SCHNEIDER (Germany) |

| Hybrid Servo | ePrAX® Hybrid System |

| Laser Safety | LazerSafe PCSS A1 + IRIS Block (Australia) |

| Linear Guides | HEIDENHAIN / GIVI (Germany) |

| Servo Motors | DELTA (Taiwan) |

| Foot Switch | SIEMENS (Germany) |

| Hydraulics | HOERBIGER (Germany) |

| Ball Screws & Guides | HIWIN (Taiwan) |

| Tooling | Manual Clamps, Punch, Die, Riser Block |

Standard Equipment

Standard Equipment

STANDARD EQUIPMENT

-

Machine: RYTEC FUSION B32.135

-

Capacity: 150 Tons x 10.6 ft.

-

CNC Control: Delem DA-66S – 24” Touchscreen, 2D/3D interface

-

Axes: Y1, Y2, X, R, Z1, Z2 + CNC Crowning

-

Crowning: RYTEC Wedge Ultra CNC Crowning System

-

Drive: HAWE ePrAX® Hybrid Servo System

-

35% energy savings

-

Increased productivity

-

Silent operation

-

Ultra-precise (+/- 0.00019”)

-

-

Safety: LazerSafe PCSS LZ2 – Ram-Mounted Safety Laser

-

Tooling:

-

Manual American Clamps

-

85° Punch

-

85° 4-Way Die

-

Riser Block

-

-

Training & Support: On-site start-up & operator training

-

Warranty:

-

3 Years / 6,240 Hours – Parts

-

1 Year / 2,080 Hours – Labor

-

-

Shipping: FOB U.S. Port, DDP

CNC CONTROL

DELEM DA-66S – 24” 2D/3D Touchscreen

With Profile-T Lite software for advanced programming, visualization, and real-time diagnostics.

Finance

Why Finance Your Equipment with Tech Financial?

Financing your equipment through Tech Financial unlocks a world of possibilities for your business. With flexible payment plans, tailored solutions, and quick credit approvals, you can preserve working capital while accessing the latest technology to stay competitive. Enjoy potential tax advantages, affordable rates, and a seamless application process designed to get you the equipment you need without delays. Tech Financial’s expertise and customer-focused approach make investing in your business’s future easier and more cost-effective than ever.

Ready to get started? Apply today and take the next step toward smarter financing!