In the world of structural steel fabrication, challenges such as labor shortages, throughput limitations, and downtime are common, particularly in industries like oil & gas, shipbuilding, and infrastructure. As a Regional Sales Executive at Mac-Tech, I, Dave Graf, am your trusted advisor and single point of contact. I deliver turnkey automation solutions that focus on maximizing ROI and ensuring operational efficiency.

Streamlining Heavy-Gauge Bending with Automation

Fabricators often struggle with the complexities of bending heavy-gauge steel, which can lead to inefficiencies and increased labor costs. Liberty Press Brakes provide an automated solution that enhances precision and speed in bending operations. By integrating Prodevco‘s advanced automation technology, fabricators can achieve faster throughput and reduce manual intervention, leading to fewer errors and less rework. I ensure seamless integration and installation, allowing your operations to quickly realize these benefits.

Maximizing ROI in Oilfield and Shipyard Fabrication

In oilfield and shipyard fabrication, the need for high-tonnage bending is critical. Liberty Press Brakes are engineered to handle the demanding requirements of these sectors, offering robust performance and reliability. With the addition of Akyapak’s cutting-edge machinery, fabricators can expect improved uptime and a significant boost in productivity. My role is to coordinate every aspect of the process, from initial planning to service, optimizing your return on investment.

Labor Savings and System Integration in Bridge Projects

Bridge construction projects often face tight deadlines and budget constraints. The integration of Ermaksan and Ercolina systems with Liberty Press Brakes allows for streamlined operations and significant labor savings. These systems work together to enhance precision and reduce the time required for complex bending tasks. My expertise ensures that the integration process is smooth and that your team receives comprehensive training to fully leverage these technologies.

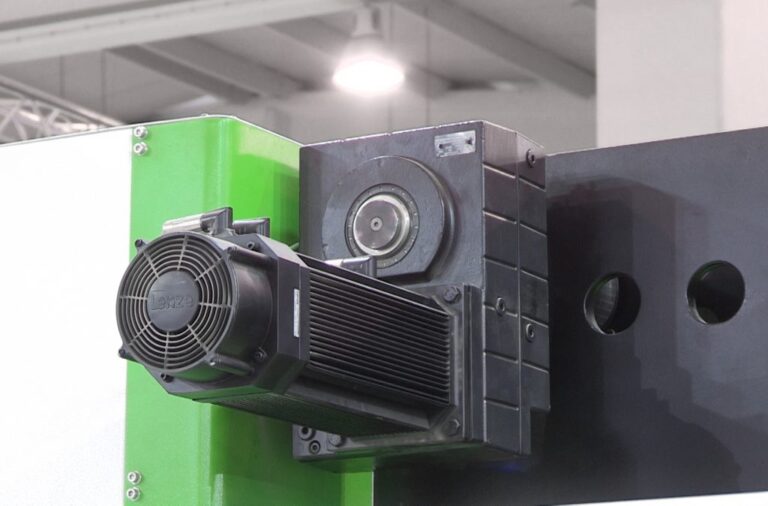

ERMAKSAN POWER-BEND FALCON BENDING MACHING

ERMAKSAN SPEED BEND PRO

Ensuring Reliability in Tower Fabrication Processes

Tower fabrication requires consistent quality and reliability. Liberty Press Brakes, when paired with HSG‘s laser and roll systems, provide a cohesive solution that minimizes downtime and maximizes output. The synergy between these systems supports high-volume production without compromising on quality. I manage the entire lifecycle of these systems, from installation to ongoing support, ensuring that your operations remain efficient and reliable.

The Role of a Single Contact in Structural Automation

Having a single point of contact simplifies the complexity of structural automation projects. I serve as that contact, coordinating all aspects of system integration, from lasers to beam systems. This approach not only reduces project timelines but also ensures that all components work harmoniously together, delivering optimal performance and efficiency.

Advanced Solutions for Efficient Fabrication

By implementing advanced solutions like Liberty Press Brakes, fabricators can overcome traditional challenges and achieve new levels of efficiency. These systems are designed to be flexible and adaptable, meeting the diverse needs of modern fabrication processes. My commitment is to deliver tailored solutions that align with your operational goals and drive success.

FAQ Section

What are the typical lead times for installation and integration?

Lead times vary based on system complexity, but I strive to minimize them through efficient project management.

How is ROI measured with these systems?

ROI is evaluated through increased throughput, reduced labor costs, and improved quality, ensuring a quick return.

What maintenance and training are required?

Regular maintenance is essential, and comprehensive training is provided to ensure your team is fully equipped.

How can lasers, rolls, and beam systems be integrated?

I coordinate seamless integration across systems, ensuring all components function together effectively.

What lifecycle support and upgrade options are available?

Lifecycle support includes regular updates and upgrades to keep your systems at peak performance.

How does Dave coordinate complex solutions?

As your single contact, I manage the entire process, from planning to execution, ensuring seamless delivery.

For executives seeking to enhance their fabrication processes, I invite you to contact me for system planning, demonstrations, or full project coordination. Let’s work together to elevate your operations to new heights.

Get Weekly Mac-Tech News & Updates