As a Sales Executive at Mac-Tech, located in the heart of the Midwest, I’ve spent years working directly with fabricators across Minnesota. My approach blends a strong Midwest work ethic with technical insights to solve real-world fabrication challenges. I’ve seen firsthand how the right technology can transform production workflows, especially in the fast-paced world of short-run, high-mix production. Today, I want to share how Rytech Brakes are revolutionizing this space, bringing unprecedented efficiency and precision to Minnesota fabricators.

Discover How Rytech Brakes Transform Production Workflows

In an industry where time is money, the ability to quickly switch between jobs is crucial. Rytech Brakes excel in shortening changeover times, which is a game-changer for low-volume, high-mix production environments. By incorporating quick-change tooling, these brakes allow operators to transition seamlessly between different tasks, minimizing downtime and maximizing productivity.

For fabricators in Minnesota, where diverse production demands are the norm, this flexibility is invaluable. Rytech Brakes streamline operations, enabling shops to handle a variety of jobs without the hassle of lengthy setup times. This not only boosts efficiency but also enhances the bottom line.

Unleash Precision with Advanced Brake Technology

Precision is at the core of Rytech Brakes’ design. With hybrid drives that combine hydraulic and electric power, these machines offer superior control and consistency. This technology reduces energy consumption, providing significant cost savings while maintaining high performance.

Rytech’s advanced software features also play a critical role in ensuring precision. They allow for easy programming and adjustments, making one-off jobs not just feasible, but profitable. This capability means fabricators can confidently take on custom orders without sacrificing quality or efficiency.

Experience Unmatched Efficiency with Rytech’s Innovative Features

Efficiency is more than just speed; it’s about doing more with less. Rytech Brakes are equipped with features that optimize every aspect of the production process. Quick-change tooling minimizes material handling, reducing the time and effort required to switch between jobs.

These brakes also integrate seamlessly with existing shop floor systems, enhancing overall workflow. The energy-efficient hybrid drives mean lower operational costs, allowing shops to invest savings back into their business for further growth and innovation.

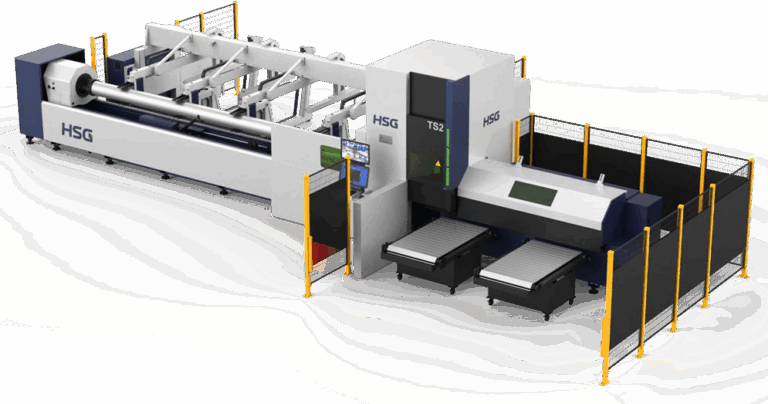

ERMAKSAN POWER-BEND FALCON BENDING MACHING

Maximize Throughput with Tailored Solutions for Minnesota Fabricators

Rytech Brakes are designed with the specific needs of Minnesota fabricators in mind. Their ability to handle a wide range of materials and job types makes them an ideal choice for shops looking to maximize throughput without compromising on quality.

By tailoring solutions to meet the unique demands of each shop, Rytech ensures that their brakes deliver optimal performance. This customization extends to machine configurations and software settings, allowing fabricators to fine-tune operations for maximum output and profitability.

Elevate Your Shop Floor with Expert Support and Training

Beyond the technology itself, Rytech provides comprehensive support and training to ensure fabricators get the most out of their equipment. This includes hands-on training sessions and ongoing technical support, empowering operators to utilize every feature of their Rytech Brakes fully.

Having expert support readily available means fabricators can quickly resolve any issues and continue production with minimal disruption. This peace of mind is invaluable in maintaining a smooth and efficient operation.

FAQ Section

What are the main benefits of using Rytech Brakes?

Rytech Brakes offer quick-change tooling, energy savings from hybrid drives, and software that makes one-off jobs more profitable.

How do Rytech Brakes improve efficiency?

They reduce changeover time and material handling, allowing for faster transitions between jobs.

Are Rytech Brakes suitable for custom jobs?

Yes, their precision and software features make them ideal for low-volume, high-mix production.

What kind of support does Rytech offer?

They provide expert training and ongoing technical support to ensure optimal use of their equipment.

Can Rytech Brakes integrate with existing systems?

Absolutely, they are designed to work seamlessly with current shop floor operations.

If you’re interested in learning more about how Rytech Brakes can enhance your shop’s efficiency, feel free to reach out. I’m here to provide any additional information or support you might need.

Get Weekly Mac-Tech News & Updates