As a Sales Executive at Mac-Tech, I’ve spent years immersed in the heart of Wisconsin’s manufacturing landscape. My Midwest work ethic and technical expertise drive my passion for helping local shops overcome real-world fabrication challenges. I understand the demands of precision and efficiency in today’s competitive market, and I’m here to introduce you to a game-changing solution: Rytech Press Brakes.

Discover How Rytech Press Brakes Revolutionize Wisconsin Manufacturing

In Wisconsin, manufacturing is more than just a business—it’s a tradition. However, many shops still rely on legacy hydraulic systems that can be cumbersome and less efficient. Rytech Press Brakes offer a modern solution, providing the same tonnage and accuracy but in a compact footprint perfect for smaller facilities. These machines are designed to fit seamlessly into your shop without sacrificing power or precision.

With Rytech, you can expect precision bending and reliable performance, allowing you to meet the diverse needs of your clients while maximizing your shop floor space. This is especially crucial for operations looking to grow without the costly investment of expanding their physical footprint.

Experience Unmatched Precision with Advanced Technology

Rytech Press Brakes are engineered with state-of-the-art technology that ensures unmatched precision in every bend. The advanced backgauge system guarantees accuracy, allowing for consistent results with every operation. This precision is critical for maintaining quality, reducing waste, and ensuring customer satisfaction.

Compared to legacy hydraulic systems, Rytech’s technology offers faster setup times and more reliable performance. This means less downtime and more productive hours on the shop floor. The precision of these machines directly translates into a more efficient production process, helping your business stay ahead of the competition.

Boost Your Shop’s Efficiency with Compact Design

One of the standout features of Rytech Press Brakes is their compact design. This allows them to fit into smaller spaces without compromising on performance. For Wisconsin shops that are tight on space, this is a significant advantage. You can maintain a high level of production without the need for large, unwieldy equipment.

The compact design also means less material handling, streamlining your assembly process and reducing the time it takes to complete each job. This efficiency not only boosts your production capacity but also reduces operational costs, making it a smart investment for any growing shop.

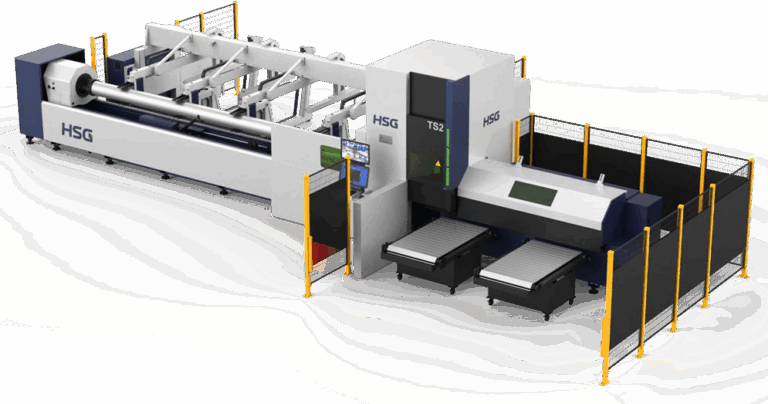

ERMAKSAN POWER-BEND FALCON BENDING MACHING

Enhance Productivity Through User-Friendly Interfaces

Rytech Press Brakes come equipped with ergonomic controls designed to minimize operator fatigue. The user-friendly interface makes it easy for operators to set up and run jobs quickly, improving overall productivity. This is a crucial factor for shops looking to maintain a competitive edge.

Operators can easily program the machine to handle various tasks, which reduces the learning curve and increases job satisfaction. By enhancing the work environment, you’re also investing in your team’s well-being, which can lead to better retention and higher morale.

Rely on Mac-Tech’s Expertise for Seamless Integration

At Mac-Tech, we’re committed to providing our clients with the best solutions for their specific needs. Our expertise in integrating Rytech Press Brakes into your existing operations ensures a smooth transition with minimal disruption. We offer comprehensive support and training to ensure your team is comfortable and confident with the new equipment.

Our goal is to help your shop achieve greater efficiency and precision, and our team is here to provide ongoing support. Whether you need technical advice or logistical assistance, Mac-Tech is your partner in success.

FAQ Section:

What are the main benefits of Rytech Press Brakes?

They offer precision, compact design, and user-friendly controls, ideal for small to medium-sized shops.

How do they compare to older hydraulic systems?

Rytech machines provide faster setup times and more consistent accuracy, enhancing productivity.

Is the investment cost-effective for smaller shops?

Yes, the efficiency and reduced material handling can lead to significant cost savings over time.

What support does Mac-Tech offer for integration?

We provide full training, technical support, and seamless integration services.

How can these machines improve operator satisfaction?

Ergonomic controls and ease of use reduce fatigue and improve job satisfaction.

If you’re ready to explore how Rytech Press Brakes can transform your shop, or if you have any questions, feel free to reach out. I’m here to help you find the perfect solution for your needs.

Get Weekly Mac-Tech News & Updates