Maximize ROI with Mac-Tech’s Turnkey Solutions and Section 179

In the fast-paced world of structural steel fabrication, industries like oil & gas, bridge building, and shipbuilding face constant pressure to innovate and streamline operations. The challenge: how to effectively integrate cutting-edge machinery while ensuring financial prudence. Enter Dave Graf, Regional Sales Executive at Mac-Tech, who serves as your trusted advisor and single point of contact. With Mac-Tech’s turnkey solutions, we simplify the complex process of equipment acquisition, creating seamless, efficient workflows. Plus, with the benefits of Section 179, there’s never been a better time to invest.

Introduction to Mac-Tech’s Turnkey Solutions

At Mac-Tech, we understand that the key to success lies in having a reliable partner who can deliver comprehensive solutions. Our turnkey approach means we handle everything from initial consultation to installation and ongoing support. By offering a single point of contact, we eliminate the headache of coordinating with multiple vendors. We work closely with you to understand your specific needs and tailor solutions that maximize productivity and ROI.

The Role of Automation in Structural Steel Fabrication

Automation is revolutionizing structural steel fabrication by reducing labor costs and increasing precision. Automated systems streamline operations, allowing for faster project completion without compromising quality. At Mac-Tech, we integrate state-of-the-art automation technologies into your production line, ensuring seamless operation and minimal downtime. Our team manages the entire process, coordinating with suppliers and internal teams to deliver a fully integrated solution.

Leveraging Section 179 for Maximum Financial Benefits

Section 179 offers a significant financial incentive for businesses looking to upgrade their equipment. By allowing you to expense purchases like beam lines and drill lines in one tax year, Section 179 simplifies both production planning and accounting. But the key is timing—purchases must be made before December 31. With Mac-Tech, you can take full advantage of these benefits, strategically planning your acquisitions to maximize tax savings.

ERMAKSAN POWER-BEND FALCON BENDING MACHING

ERMAKSAN SPEED BEND PRO

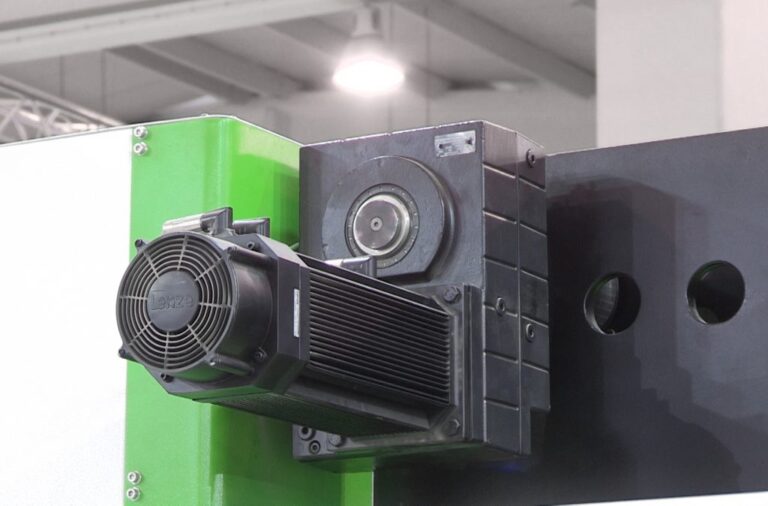

Key Machines: Prodevco, Liberty, and Ermaksan

Prodevco, Liberty, and Ermaksan machines stand out as leaders in the industry, offering unparalleled efficiency and precision. These machines are engineered to handle the demands of heavy industrial applications, reducing manual labor and minimizing errors. At Mac-Tech, we ensure these machines are integrated smoothly into your existing operations, providing training and support to optimize their performance.

Enhancing Efficiency with Ercolina, HSG Fiber Lasers, and Akyapak

Ercolina’s bending machines, HSG Fiber Lasers, and Akyapak’s versatile systems are game-changers in enhancing production efficiency. These technologies offer speed and accuracy, significantly reducing production time. Our team at Mac-Tech manages the installation and integration process, ensuring that you achieve the highest levels of operational efficiency and cost savings.

Real-World Success in Oilfield, Bridge, Shipyard, and Tower Operations

Our turnkey solutions have delivered impressive results across various industries. In oilfield operations, our integrated systems have streamlined production, reducing costs and improving delivery times. For bridge and shipyard projects, our equipment has enhanced precision, ensuring safety and reliability. Tower operations benefit from our machinery’s ability to handle complex structures with ease. With Mac-Tech, your success is our priority.

FAQ Section

What criteria should I consider when purchasing structural steel equipment?

Consider factors like production capacity, integration with existing systems, and financial incentives such as Section 179.

How does Mac-Tech ensure seamless integration of new machinery?

We coordinate with suppliers and internal teams to manage the entire integration process, providing comprehensive support and training.

What are the lead times for acquiring and installing new equipment?

Lead times vary by machine, but we work diligently to ensure timely delivery and installation to meet your project deadlines.

How does automation impact labor requirements?

Automation reduces the need for manual labor, allowing your team to focus on high-value tasks and improving overall efficiency.

Can Mac-Tech provide solutions for custom fabrication needs?

Yes, we offer tailored solutions to meet specific project requirements, ensuring optimal performance and ROI.

How do I maximize the benefits of Section 179?

Plan your purchases strategically before December 31 to take full advantage of the immediate expensing benefits.

Why choose Mac-Tech as a single point of contact?

We provide comprehensive, end-to-end solutions, simplifying the procurement and integration process with minimal hassle.

Get Weekly Mac-Tech News & Updates