-

OEM Punch Holder Height Compatibility Reduces Setup Time, Scrap

Pat O’Neill explains how standardizing OEM punch holder height compatibility streamlines coil-fed forming operations by reducing setup time and minimizing trial adjustments. With consistent tooling heights, operators achieve better forming accuracy, more stable hit-to-hit performance, and fewer dimensional errors that drive scrap. The article emphasizes making smarter forming and coil-fed system choices to boost throughput,…

-

Resolving Clamping Issues in Rytech Press Brakes

In “Resolving Clamping Issues in Rytech Press Brakes,” Nicole Salato offers strategies for fabrication shops to prevent breakdowns, replace worn parts, and plan reliable service schedules. Contact: Nicole Salato Service & Parts Lead – Mac-Tech nicole@mac-tech.com

-

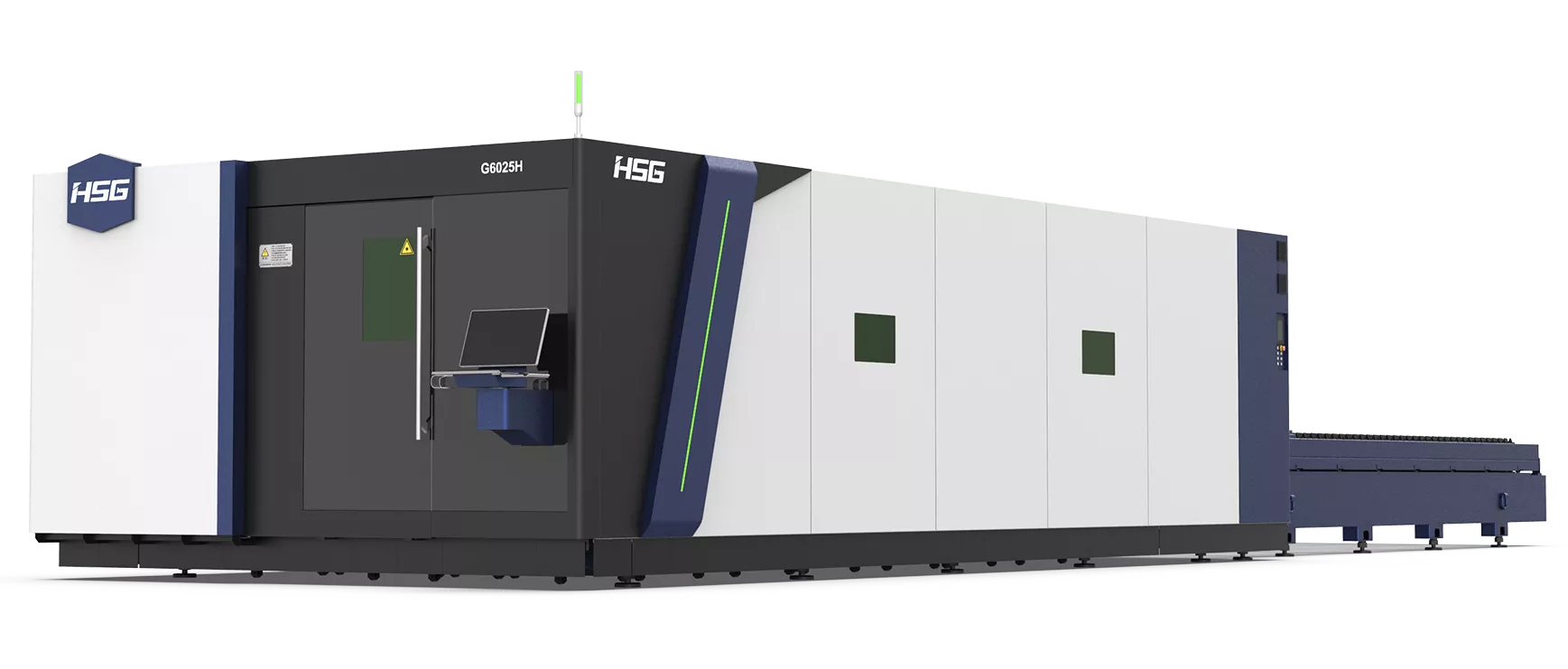

Midwestern Manufacturers Choose 12kW HSG Lasers for Efficient Thick Plate Cutting: Real Data on Speed, Energy, and Edge Quality

Kyle Bialozynski’s article highlights Midwestern manufacturers opting for 12kW HSG lasers to enhance thick plate cutting. With field expertise, Kyle emphasizes smart fabrication solutions and customer satisfaction. Kyle Bialozynski – Sales Executive, Mac-Tech kyle@mac-tech.com | 414-704-8413

-

Boost ROI: Mac-Tech’s Advanced Fabrication Solutions & Section 179

Dave Graf, Regional Sales Executive at Mac-Tech, highlights how advanced fabrication solutions enhance ROI for structural steel decision-makers in oil & gas, shipbuilding, and construction. He emphasizes leveraging Section 179 tax benefits, positioning himself as the go-to expert for complete automation solutions.

-

Ermaksan Press Brakes Give Shipyards Precise Control on Large Hull Plate

See how advanced forming technology boosts hull quality, cuts rework, and de-risks capital planning for modern shipyards. Joe Ryan President, Mac-Tech joe@mac-tech.com | 414-477-8772 | 888-MAC-9555

-

Manual Lever Express Clamps Cut Press Brake Changeover Time

Pat O’Neill explains how manual lever express clamps can reduce press brake changeover time, helping shops maintain higher throughput and more consistent part quality. By simplifying tool clamping and improving setup repeatability, operators can hold forming accuracy, minimize handling errors, and cut scrap and rework. The article emphasizes choosing forming solutions and coil-fed system approaches…

-

Optimize ROI with Ermaksan Press Brakes: Precision & Section 179 Savings

John Perry guides buyers to boost efficiency and profits by choosing the right Ermaksan press brake, highlighting precision and Section 179 tax savings.

-

Phased Upgrades to Integrated Cells, Lower Risk

Learn how phased upgrades to integrated cells cut risk, modernize fabrication, and boost ROI with practical steps from Mac-Tech VP Adam Quoss.