News

Mac-Tech Metal Fabrication News

-

Boost Efficiency with Dual Up-Down CNC Roofing Folders

Discover unparalleled efficiency with our Dual Up-Down CNC Roofing Folders, designed to streamline operations and maximize productivity in your roofing projects.

-

I Drive Press Brake Innovation with Automatic Crowning for Consistent, Precise Bends

John Perry, Regional Sales Executive at Mac-Tech, reveals how automatic crowning in press brake technology consistently delivers precise, repeatable bends—cutting down on rework and boosting throughput. Fueled by deep industry experience, John’s consultative, solutions-driven approach sheds light on strategic tooling and laser integration that can streamline operations, reduce setup times, and produce measurable ROI. Decision-makers…

-

Reducing Material Distortion with Precision Laser Welding

I showcase laser welding that cuts distortion for top results. Trust my meticulous approach. – Nathan Betthauser (nateb@mac-tech.com | 414-391-8683)

-

I Evaluate Press Brakes vs. Metal Folding Machines to Boost Roofing Efficiency

I bring local roots, customer focus, and compare press brakes & metal folding for top roofing solutions. –Pat O’Neill, Mac-Tech (pat@mac-tech.com, 414-232-7929)

-

How I Drive Unprecedented Efficiency and Cost Savings with High-Speed Beam Coping

Ready to revolutionize your structural steel fabrication and maximize ROI? In this high-impact piece, Dave Graf, Regional Sales Executive at Mac-Tech, uncovers the game-changing power of high-speed beam coping to slash costs, accelerate project timelines, and drive operational excellence. By adopting innovative coping solutions, industry leaders can overcome persistent bottlenecks, free up valuable resources, and…

-

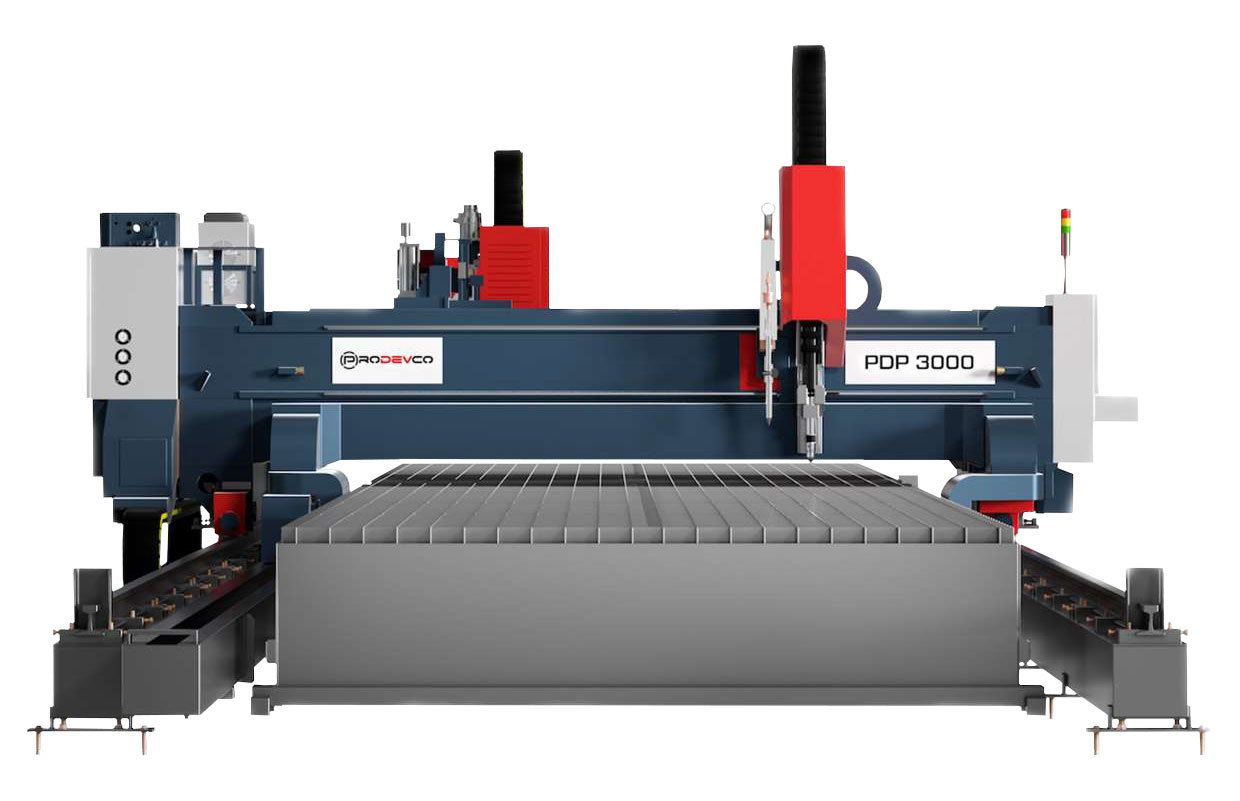

How I Drive Faster Profits with Prodevco’s Automated Beam Processing

In a fiercely competitive structural steel marketplace, every minute on the shop floor translates into real dollars—and real risk. In this article, Dave Graf, Regional Sales Executive at Mac-Tech, showcases how Prodevco’s Automated Beam Processing delivers faster throughput, slashes labor needs, and cuts rework to help your bottom line soar. If you’re grappling with tight…

-

Guiding Clients to Laser Solutions in Metal Fabrication

Discover precise laser solutions for metal fabrication. Joe Ryan Sales Engineer, Mac-Tech 715-544-5968 nathan@mac-tech.com

-

My Consultative Approach to Prodevco’s Automated Solutions

I tailor automated solutions for maximum satisfaction. Adam Quoss Vice President of Sales, Mac-Tech aquoss@mac-tech.com