Pat O’Neill

Pat O’Neill

Regional Sales Executive of Americas/National Product Manager

Born and raised in the southern suburbs of Chicago, graduated from Illinois State University where I also played rugby, moved to Milwaukee in 1991 and continued to play rugby for another 8 years. Married for over 30 years to my wife Lezli we have 2 sons and we love Wisconsin, Milwaukee and the Brewers.

related Articles

Seamless Automation: Panel Benders in Coil-to-Part Lines

In the article Seamless Automation: Panel Benders in Coil-to-Part Lines, Pat O’Neill, a National Product Manager and Regional Sales Executive at Mac-Tech, discusses how manufacturers can enhance production efficiency, forming accuracy, and line reliability. Pat emphasizes the importance of selecting the right machines and integrating automation into manufacturing processes. He advocates for real-world planning to ensure seamless operations and optimal performance. By focusing on these strategies, Pat assists manufacturers in achieving more productive and reliable production lines. Pat O’Neill National Product Manager / Regional Sales Executive, Mac-Tech pat@mac-tech.com | 414-232-7929Unlock Precision and Speed with CNC Folder Upgrade

Pat O’Neill, a National Product Manager and Regional Sales Executive at Mac-Tech, discusses enhancing production efficiency through CNC folder upgrades. He emphasizes the importance of precision and speed in manufacturing and explains how advanced roll forming, folding, and coil-fed fabrication systems can significantly improve these aspects. Pat assists customers in optimizing their production processes by implementing these technologies, leading to increased output and reduced costs. For further inquiries or assistance, Pat can be contacted at pat@mac-tech.com or 414-232-7929.Stefa Gutter Roll Forming Cuts Scrap, Improves Throughput

The article explains how Stefa gutter roll forming boosts productivity by making smarter roll-forming and coil-fed system choices. By optimizing forming stations, tooling, and material handling, the line maintains tighter profiles and more consistent cut lengths, reducing rework and scrap. Integrated coil feeding, controls, and cutoff coordination improve speed without sacrificing accuracy, while better guidance, tensioning, and changeover practices increase uptime. The result is higher throughput, improved forming reliability, and steadier output quality. Pat O’Neill National Product Manager / Regional Sales Executive, Mac-Tech pat@mac-tech.com | 414-232-7929Choosing Hybrid Over Electric Drives in Rytech Systems: Cost and Precision Benefits

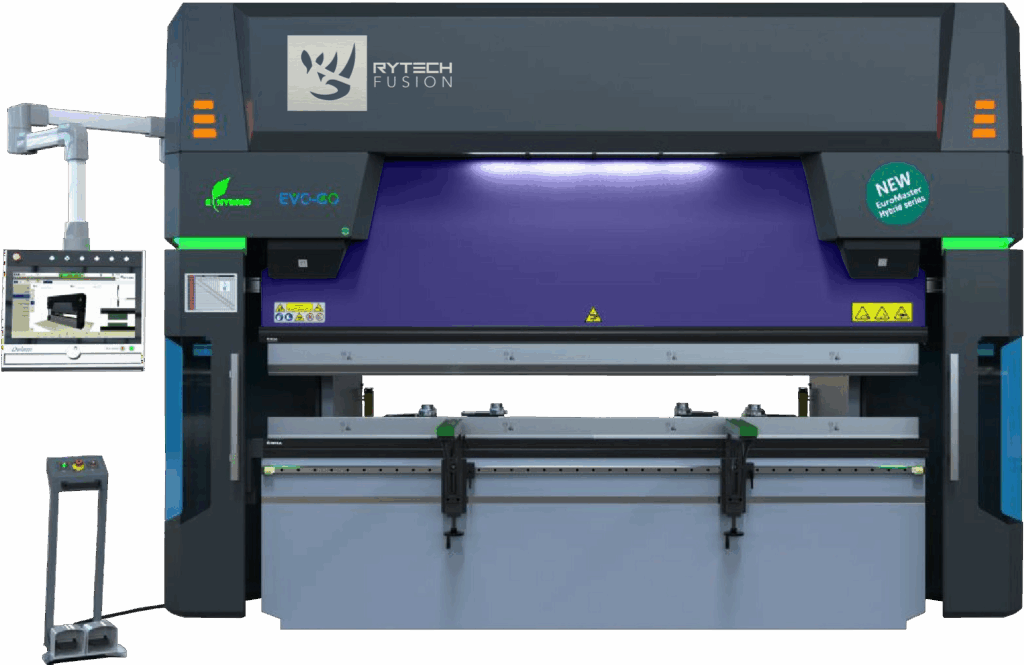

The article by Patrick O’Neill discusses the advantages of choosing hybrid drives over electric ones for Rytech Systems, focusing on cost-effectiveness and precision. Pat emphasizes how manufacturers can enhance production efficiency, forming accuracy, and line reliability by selecting the right machinery, incorporating automation, and engaging in practical planning. He provides insights on optimizing manufacturing processes to achieve better outcomes. Pat O’Neill National Product Manager / Regional Sales Executive, Mac-Tech pat@mac-tech.com | 414-232-7929CNC Panel Benders: Cut Setup Time with Software Presets

In the article, CNC Panel Benders: Cut Setup Time with Software Presets, Patrick (Pat) O’Neill discusses strategies to enhance manufacturing efficiency, accuracy, and reliability. He emphasizes the importance of selecting the right machines, implementing automation, and engaging in practical planning. By using software presets, manufacturers can significantly reduce setup times, leading to improved production processes. Pat offers insights into optimizing operations through advanced technology and thoughtful decision-making. Pat O’Neill National Product Manager / Regional Sales Executive, Mac-Tech pat@mac-tech.com | 414-232-7929Tool-Free Clamp Plate Removal Cuts Press Brake Downtime

Pat O’Neill explains how tool-free clamp plate removal and smarter press brake setup choices reduce downtime and stabilize production. By speeding changeovers and improving access for maintenance, shops increase throughput while keeping bends consistent. Combined with informed forming decisions and coil-fed system selection, the approach boosts forming accuracy, lowers scrap from misalignment and handling, and improves overall line reliability by minimizing interruptions and variation. Pat O’Neill National Product Manager / Regional Sales Executive, Mac-Tech pat@mac-tech.com | 414-232-7929Efficient Shearing Lines: Elevate Productivity with Smart Material Handling

In the article “Efficient Shearing Lines: Elevate Productivity with Smart Material Handling,” Pat O’Neill discusses strategies to enhance manufacturing productivity. He emphasizes the importance of selecting the right machines, integrating automation, and employing practical planning to improve production efficiency, forming accuracy, and line reliability. By focusing on these areas, manufacturers can significantly boost their operational performance. Pat O’Neill National Product Manager / Regional Sales Executive, Mac-Tech pat@mac-tech.com | 414-232-7929Precision Forming with Optimal Roll Diameter Selection

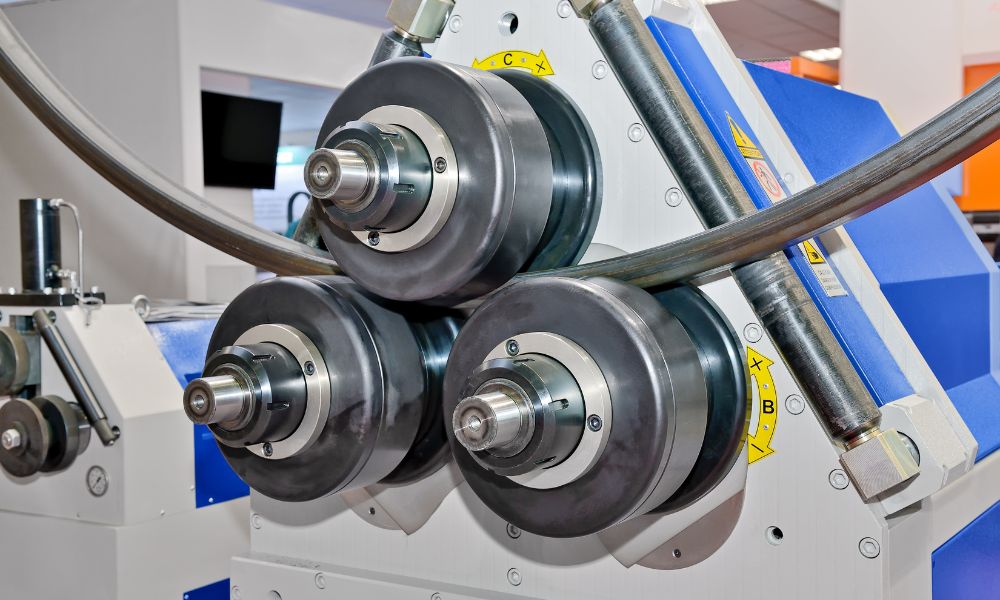

The article by Patrick O’Neill discusses how manufacturers can enhance production efficiency, forming accuracy, and line reliability by selecting the optimal roll diameter for precision forming. Pat emphasizes the importance of choosing the right machinery, integrating automation, and planning based on real-world conditions to achieve better results. His expertise helps manufacturers streamline their processes and improve overall performance. Pat O’Neill National Product Manager / Regional Sales Executive, Mac-Tech pat@mac-tech.com | 414-232-7929Up Down Panel Benders Deliver Faster Safe Long-Panel Folding

Pat O’Neill explains how up-down panel benders speed production and enhance safety when folding long panels by automating consistent, bidirectional forming. He emphasizes choosing coil-fed, integrated systems that stabilize material flow, reduce handling, and maintain tight bend tolerances across varied profiles. With smarter forming strategies and equipment selection, shops can boost throughput, improve forming accuracy, cut scrap and rework, and increase line reliability through repeatable setup, fewer changeovers, and dependable downstream coordination. Pat O’Neill National Product Manager / Regional Sales Executive, Mac-Tech pat@mac-tech.com | 414-232-7929Dual-Direction Folding Elevates Architectural Panel Precision

The article by Pat O’Neill discusses how manufacturers can enhance production efficiency, forming accuracy, and line reliability by selecting the right machines and incorporating automation. O’Neill emphasizes the importance of dual-direction folding technology in architectural panel production, highlighting its role in improving precision. He also advises on real-world planning to ensure optimal machine performance and reliability. For further guidance, Pat O’Neill can be contacted at: Pat O’Neill National Product Manager / Regional Sales Executive, Mac-Tech pat@mac-tech.com 414-232-7929Expand Forming Flexibility with Section 179 Tax Savings

Pat O’Neill discusses how businesses can enhance their production capabilities by leveraging Section 179 tax savings. He emphasizes the benefits of investing in advanced roll forming, folding, and coil-fed fabrication systems. By utilizing these technologies, companies can increase efficiency and flexibility in their manufacturing processes. Pat provides insights into optimizing production workflows and reducing costs through strategic equipment upgrades. For more information, Pat can be contacted at pat@mac-tech.com or 414-232-7929.Double Folders: Speedy ROI with Section 179 Benefits

Pat O’Neill, a National Product Manager and Regional Sales Executive at Mac-Tech, discusses how customers can achieve a rapid return on investment by utilizing double folders and taking advantage of Section 179 tax benefits. He emphasizes the efficiency and cost-effectiveness of roll forming, folding, and coil-fed fabrication systems in enhancing production processes. By integrating these advanced technologies, businesses can streamline operations and boost productivity. For further assistance, Pat can be contacted at pat@mac-tech.com or 414-232-7929.