SMD 3 S – EDITION

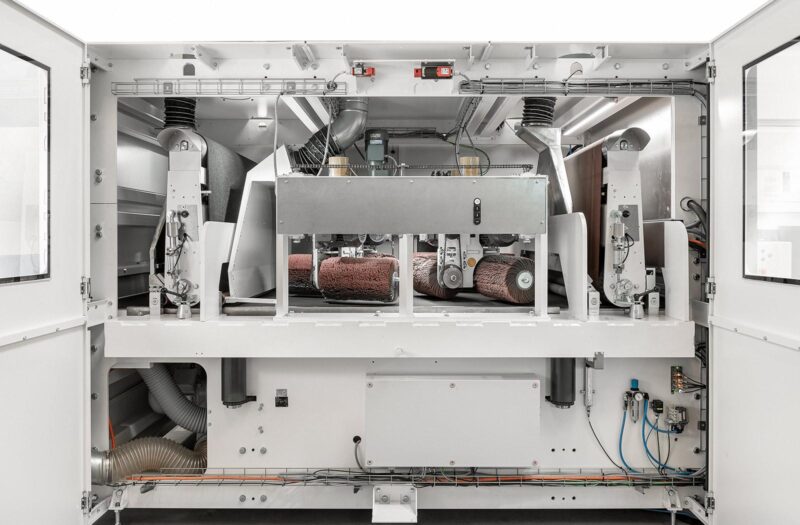

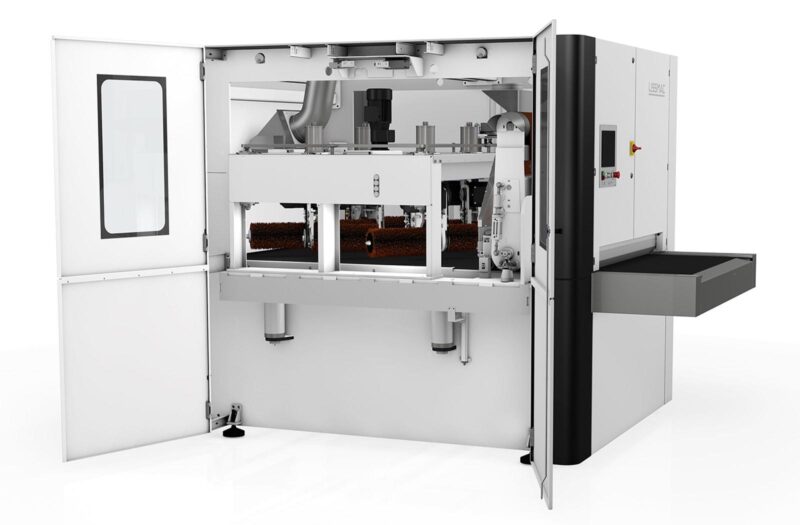

The LISSMAC – SMD 3 series grinding and deburring machines can be used for a wide variety of customer requirements. The SMD 3 S-Edition is ideal for processing laser and punched parts and also for deburring small thin sheet metal parts. Thanks to several round brushes, even edge rounding and directionless finishing are possible.

SMD 3 S – EDITION

Description

Description

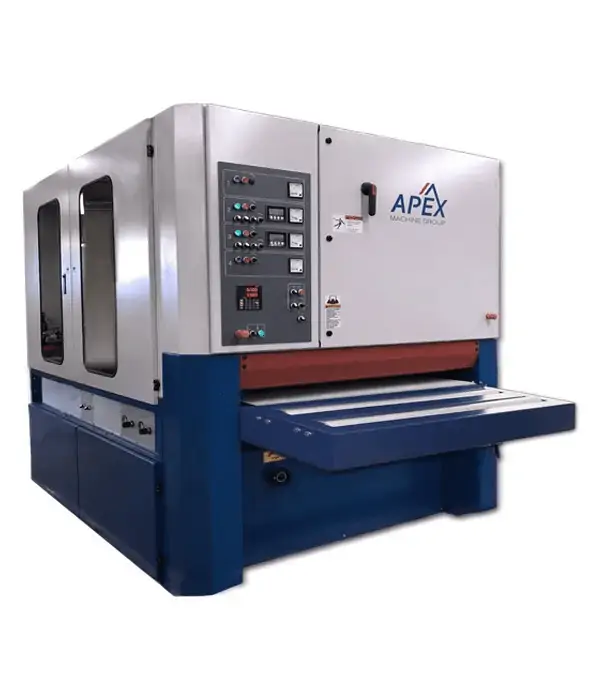

The universal grinding and deburring machine for thin sheet metal impresses with high quality results in edge rounding and surface grinding.

The LISSMAC – SMD 3 series grinding and deburring machines can be used for a wide variety of customer requirements. The SMD 3 S-Edition is ideal for processing laser and punched parts and also for deburring small thin sheet metal parts. Thanks to several round brushes, even edge rounding and directionless finishing are possible.

The S-Edition gives impressive results on the edge and surface sanding. The dry grinding and deburring machines can be used to remove excess burrs and the oxide layer on one side, as well as producing a good surface finish and edge rounding up to a radius of 2 mm. Stainless steel, steel, aluminum and non-ferrous parts can be processed. Edges can be rounded over the entire working width of the machine. In addition, the grinding and deburring machines score with an easy to use high-end control panel, a constant table height for ergonomic work and the possibility of automation and integration into production lines. Thanks to the space-saving design, the grinding and deburring machines require 30% less installation space.

Specifications

Specifications

Technical data

SMD 133 DRE

- working width max. 950 mm

- material thickness max. 3 – 100 mm

- load 300 kg/rm

- voltage 400 V / 50 Hz

- network structure 3~ PEN / 3~ PE+N

- total current consumption 51,4 A

- total power 23,5 kW

- insulation class IP 42

- infinitely variable feed speed 0.5 – 8 m/min

- adjustment of material thickness electric

- adjustment of tools manual

- weight approx. 2900 kg

- dimensions (W/D/H) approx. 1600/2600/1900 mm

SMD 133 RE USA

- working width max. 950 mm

- material thickness max. 3 – 100 mm

- load 300 kg/rm

- voltage 480 V / 60 Hz

- network structure 3~ PEN / 3~ PE+N

- total current consumption 51,4 A

- total power 23,5 kW

- insulation class IP 42

- infinitely variable feed speed 0.5 – 8 m/min

- adjustment of material thickness electric

- adjustment of tools manual

- weight approx. 2900 kg

- dimensions (W/D/H) approx. 1600/2600/1900 mm

Additional Features

Additional Features

Further information

- Removing slag,deburring and edge rounding in one throughfeed pass, saves time

- The high quality and solid construction of the machine guarantees a long lifetime

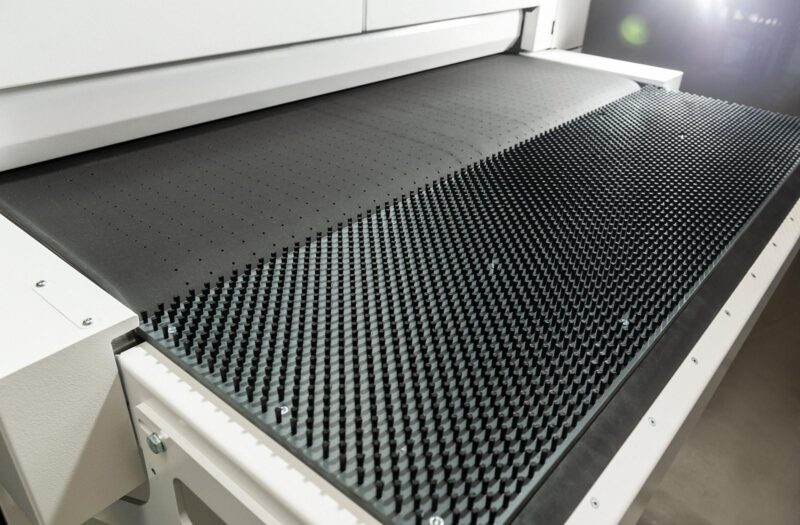

- The mechanical removal of slag by power-pins gives long tool life and reduces grinding costs enormously

- A soft, large diameter, contact roller, enables to process warped parts and accepts thickness tolerances

- Our 2 rotary heads give a perfectly even edge rounding

- Both mild- and stainless steels can be processed

- The compact construction of the machine requires limited floor space

- The serrated infeed pressure rollers quarantee a safe and easy feeding of parts

- The ergonomical and intuitive controls make it easy to operate the machine

- The individual operation of each head guarantees an optimum flexibility of the machine for various applications

- The optimum accessibility of the machine enables easy tool change, cleaning and maintenance

Finance

Why Finance Your Equipment with Tech Financial?

Financing your equipment through Tech Financial unlocks a world of possibilities for your business. With flexible payment plans, tailored solutions, and quick credit approvals, you can preserve working capital while accessing the latest technology to stay competitive. Enjoy potential tax advantages, affordable rates, and a seamless application process designed to get you the equipment you need without delays. Tech Financial’s expertise and customer-focused approach make investing in your business’s future easier and more cost-effective than ever.

Ready to get started? Apply today and take the next step toward smarter financing!