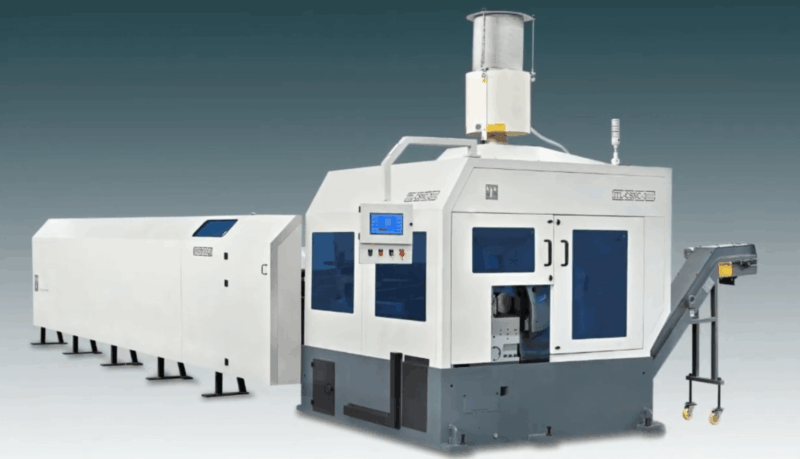

HYDMECH CSNC-175

Designed for Operator Safety

Designed for operator safety, this machine is completely enclosed and features safety door interlocks which if a door opens during operation, the machine will shut off.

Achieve consistent results with this carbide sawing machine that features a high level of productivity, length accuracy, and clean, burr free cuts.

Featuring a 1.97” – 6.9” round capacity at 90°, 40 HP motor, and a 560 mm blade, the CSNC-175 is a versatile high-speed cutting machine.

HYDMECH CSNC-175

Description

Description

Designed for Operator Safety

Specifications

Specifications

| Cutting Capacity Round 90° | 1.96″- 7″ |

| Cutting Capacity Square 90° | 1.96″-5.11″ |

| Blade Drive | 40 HP VFD |

| Blade Speed | 164-656 SFM |

| Blade Size | Carbide/Cermet tipped: 22″ x 0.12″ kerf |

| Bar Stock Length | 10′-20′ |

| Trim Cut | Zero or programmable from 0.4′ or longer |

| Cut off Length | Min 0.4″ up to full bar length |

| Single Stroke | 40″ |

| Remnant Length | 4.72″ + cut length |

| Hydraulic Motor | 3 HP VFD |

| Bar Loading Magazine | Inclined storage width of 55″ for rounds |

| Machine Capacity | 19,800 lbs. |

| Machine Weight | 12,100 lbs. |

| Dimensions (w x l x h) | 97” x 104” x 70” |

Standard Features

Standard Features

STANDARD FEATURES

- Mitsubishi PLC Controller allows for 200 programs to be saved.

- Job monitoring with cycle time, job duration, parts count, and tool life

- Comprehensive US steel grades menu with ability to add custom material grades

- Bar feed features a material gripper feed carriage indexing via ball screw and AC servo drive

- Heavy duty saw head is driven by ball screw and AC servo drive

- Mist exhaust

- Bar retracts automatically for contact free return stroke of the saw blade

- Bar Loader with safety guard sheets provides inclined storage width of 55” (1400mm) for rounds

- PLC controller, automatic oil lubrication of all moving parts

- Output sorting ensures trim cuts and remnant pieces are sorted automatically from good parts

- Variable vise pressure control with dial gauge – two stations

- Blade lubrication features triple jet system to lubricate blade tip and sides

- Hydraulic rotating wired chip brush rotates in both directions for proper chip removal

- Status indicating tower

- Chip auger

- Air cooled electric magnetic particle clutch

- Built in hydraulic tank and power pack

- Tool steel hardened saw guide plates

- Power transformer

- Air moisture separator

- Cooling nozzle

- Four blade starter package

Optional Features

Optional Features

OPTIONAL FEATURES

- Auto bar loader for non-rounds

- PLC program change

- Bundle loaders – max weight 4 tons

- Track chip conveyor

- Maintenance kit

- Long cut bar out feed motorized conveyor table in the following lengths – 1000 mm, 2000 mm, and 3000 mm

Finance

Why Finance Your Equipment with Tech Financial?

Financing your equipment through Tech Financial unlocks a world of possibilities for your business. With flexible payment plans, tailored solutions, and quick credit approvals, you can preserve working capital while accessing the latest technology to stay competitive. Enjoy potential tax advantages, affordable rates, and a seamless application process designed to get you the equipment you need without delays. Tech Financial’s expertise and customer-focused approach make investing in your business’s future easier and more cost-effective than ever.

Ready to get started? Apply today and take the next step toward smarter financing!