DR. HOCHSTRATE 3200*6

Brand – DR. HOCHSTRATE

Model – 3200 X 6

Type – Folding Machines

Condition – New – In Stock

DR. HOCHSTRATE 3200*6

Description

Description

Specifications

Specifications

SPECIFICATIONS

| Max Thickness | 0.2362″ |

| Overall Length | 10.5′ |

Equipped With

Equipped With

EQUIPPED WITH

- Hydraulic driven upper and bending beam

- 45 degree upper beam angle

- Interchangeable upper and lower bending beam tooling rails

- Foot Switch for manual and automatic operation

- Safety stop at approx. 25mm (¼”) upper beam height

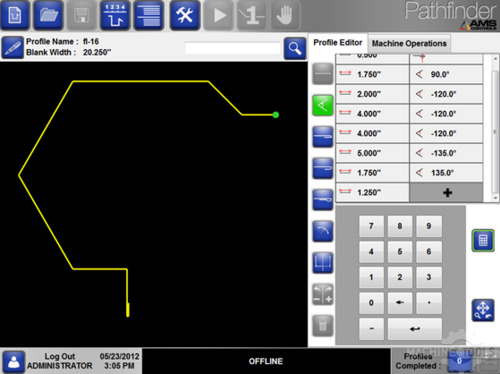

- Operating panel with: indication of bending angle, preselection of bending angle, foot switch to operate upper and bending beam, and automatic mode

- Control System: PLC-Siemens-S7

- CE-Certification

- Patented Dynamic Hydraulic Camber System

- Achieve excellent bending results over the full length

- Bend any angle regardless of length and thickness over the full length

- Conventional systems are only able to bend specific thicknesses at specific angles with a specific mechanical camber

- Motor controlled back gauge 39″ range (1000 mm) with electronic position backgauge indicator

- Easily manageable control panel allows precise setting to desired backgauge dimension

- Backgauge adjusts accordingly

- Ideal for making many different bends eliminating manual measuring

- Additional back gauge lengths and configurations available upon request

- Electric/hydraulic adjustment of bending beam

- Easy to read with selector switch

- Accurately sets the distance between bending beam and lower beam

- Setting is done quickly for different sheet thickness and bending radii

- Includes Automatic Sheet Thickness detection

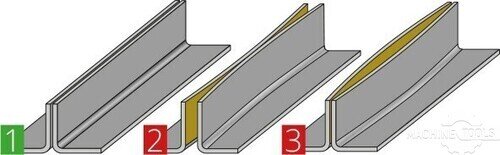

- Complete set segmented goats foot tooling with clamping rail

- Height 100 mm

- Capable of bending up to 4 mm (9 gauge mild steel with a strength of 400 n/mm2)

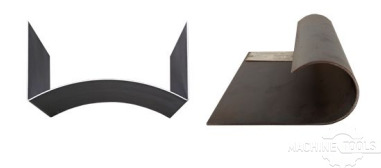

- Round bending function with initial round bending

- For forming half (180 deg.) and three-quarter (270 deg.) tube shapes with no tool change

- Parts are free of step marks and no special tools are required

- Upper beam pressure regulator

- Allows selection of correct pressure to clamp sheet metal with sensitive surfaces

- Pressure regulation is beneficial for bending aluminum, patterned plates, tread grip and similar materials

Spec Sheet

Spec Sheet

SPEC SHEET

- Max Sheet Thickness .236″/6 mm (tensile strength 400 N/mm2)

- Bending Length: 126″/3200 mm

- Max bending angle approx. 130 degrees

- Minimum inner radius 2 x sheet thickness

- Minimum flange Length 10 x sheet thickness

- Stroke upper beam approx. 300 mm

Finance

Why Finance Your Equipment with Tech Financial?

Financing your equipment through Tech Financial unlocks a world of possibilities for your business. With flexible payment plans, tailored solutions, and quick credit approvals, you can preserve working capital while accessing the latest technology to stay competitive. Enjoy potential tax advantages, affordable rates, and a seamless application process designed to get you the equipment you need without delays. Tech Financial’s expertise and customer-focused approach make investing in your business’s future easier and more cost-effective than ever.

Ready to get started? Apply today and take the next step toward smarter financing!