BeamMaster Robotic Welding System

Videos BeamMaster Robotic Welding System

BeamMaster Robotic Welding System

Description

Description

Fit + Weld Automation for Structural Steel — Now Available from Mac-Tech

The AGT Robotics BeamMaster is the world’s #1 robotic welding solution for structural steel — engineered to eliminate manual bottlenecks, reduce skilled labor dependence, and dramatically increase throughput. Powered by Cortex auto-programming, SnapCam 3D vision, and optional LayoutMaster AR fitting, BeamMaster brings true autonomous welding to high-mix/low-volume production.

Whether you’re fabricating W-beams, columns, HSS, channels, or complex assemblies, the BeamMaster turns your shop into a fast, predictable, high-output production line — with Mac-Tech’s 40+ years of structural fabrication expertise behind you.

Key Features

Key Features

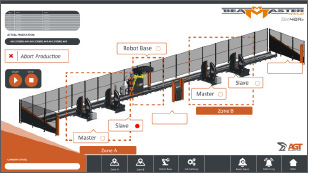

Autonomous Fit + Weld in One System

BeamMaster can fit, tack, and weld with near-zero operator intervention — letting a single operator manage dual working zones. While the robot welds in Zone A, your operator loads and fits in Zone B for continuous flow production.

Highlights:

-

100% Fit + Weld with one operator

-

Dual-zone workflow doubles productivity

-

Safe laser-curtain work zones

-

Autonomous beam rotation (optional) for horizontal-position welding

-

Minimal crane handling — load once, unload finished

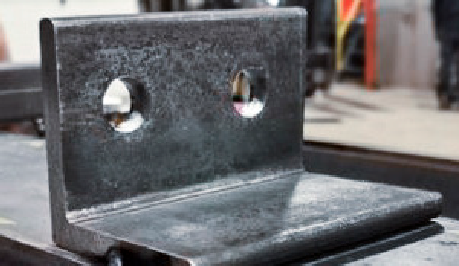

Flexible Part Handling & Beam Types

BeamMaster handles the widest variety of structural profiles:

-

W-beams / H-beams

-

HSS, channels

-

Columns, fabricated beams (straight, tapered, double-tapered)

-

Panels, sub-assemblies, skids, miscellaneous weldments

If it fits in the envelope, BeamMaster can weld it.

Configurations to Match Your Workflow

AGT offers a modular design that grows with your shop, giving you long-term scalability.

BeamMaster Single Zone – 1 Robot

-

Cortex + SnapCam

-

1 welding zone up to 44 ft

-

1 pair of rotators

-

Fanuc welding robot

-

Lincoln Electric welding power source

BeamMaster Dual Zone – 1 Robot

-

Everything in Single Zone

-

Larger custom welding zone

-

Second set of rotators

BeamMaster Twin – Dual-Zone, 2 Robots

-

Highest throughput configuration

-

Ideal for higher volume shops

-

Simultaneously weld two beams or double-team one

Specifications

Specifications

General System Specs

| Feature | Specification |

|---|---|

| System Type | Autonomous Robotic Fit + Weld System |

| Working Zones | Single Zone / Dual Zone / Twin (2 Robots) |

| Beam Rotator Capacity | 10,000 lb per pair |

| Typical Length Capacity | Up to 44 ft per zone (customizable) |

| Footprint Fence-to-Fence | 112 ft (34.1 m) total footprint |

| Dual-Zone Total Length | 95 ft (29.0 m) combined EWZ1 + EWZ2 length |

| Zone Lengths | 40 ft per zone (standard) |

| Height | 13 ft (3.95 m) |

| Compatible Profiles | W-Beams, H-Beams, HSS, Channels, Columns, Fabricated Beams (Straight/Tapered), Panels, Delta Beams, Misc. Assemblies |

Welding Specifications

Welding Specifications

Welding Specifications

| Welding Category | Details |

|---|---|

| Welding Processes | MCAW (Spray/Pulse, ISO 4063 Process 138) / GMAW (Spray/Pulse, ISO 4063 Process 135) |

| Preferred Filler Metal | MCAW: E70C-6M H4 (Hobart Fabcor Edge 0.045″) |

| Alternate Filler | GMAW: ER70S-6 (Lincoln SuperArc L-59 0.045″) |

| Shielding Gas Options | 85% Ar / 15% CO₂ (M20) or 90% Ar / 10% CO₂ (M20) |

| Fillet Weld Travel Speed – 3/16″ | 20 in/min (8.4 mm/s) |

| Fillet Weld Travel Speed – 1/4″ | 15 in/min (6.4 mm/s) |

| Fillet Weld Travel Speed – 5/16″ | 10 in/min (4.6 mm/s) |

| Surface Requirements | Clean beams; procedures for sandblasted or mill-scale surfaces (highest quality on sandblasted) |

| Gap Detection | No gap detection (uses 3D point-cloud joint finding) |

| Joint Detection | 3D Camera Point Cloud seam finding (SnapCam) |

Performance & Welding Specifications

-

Fillet weld travel speeds:

• 3/16″ – 20 in/min (8.4 mm/s)

• 1/4″ – 15 in/min (6.4 mm/s)

• 5/16″ – 10 in/min (4.6 mm/s) -

Processes:

• MCAW (Spray & pulse) – ISO 4063 Process 138

• GMAW (Spray & pulse) – ISO 4063 Process 135 -

Welding Wire:

• MCAW: E70C-6M H4

• GMAW: ER70S-6 -

Gas Mixes:

• 85% Ar / 15% CO₂

• 90% Ar / 10% CO₂ -

Beam Rotator Capacity:

• 10,000 lb per pair

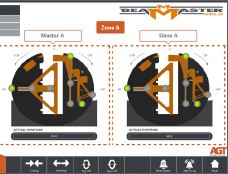

Software & Vision System

Software & Vision System

Software & Vision System

| Feature | Specification |

|---|---|

| Auto-Programming Engine | Cortex (no-programming welding automation) |

| CAD Integration | Tekla, SDS2, Advance Steel, Bocad, and more |

| Vision System | SnapCam 3D robotic vision system with point-cloud seam finding |

| SnapCam Advantages | Auto path correction, extended working distance, up to 30% faster throughput vs. laser sensors |

| AR Fitting System (Optional) | LayoutMaster – projects part contours, welds, and fit data via colored laser projection |

Configurations

Configurations

Configurations

| Model | Description | Included Components |

|---|---|---|

| BeamMaster Single Zone – 1 Robot | Base configuration | Cortex, SnapCam, Fanuc welding robot, Lincoln welding power source, HMI, installation, training, 1 pair of rotators |

| BeamMaster Dual Zone – 1 Robot | Additional work zone for higher throughput | Everything in Single Zone + extended welding zone + second pair of rotators |

| BeamMaster Twin – Dual Zone, 2 Robots | Highest productivity; weld two beams or dual-robot single-beam weld | Everything in Dual Zone + second welding robot |

Software

Software

Cortex – No-Programming Auto-Weld Software

Cortex automatically creates robot programs for every unique beam in a building model — even when none of them are identical.

Benefits:

- Batch-process an entire building in one click

- Generates weld locations, weld sizes, sequences, and heat-management

- Integrates with Tekla, SDS2, Advanced Steel, Bocad, and more

- No robot programming required

- Powerful simulation and path optimization

SnapCam – Advanced 3D Vision for Real-World Fabrication

Fabricated beams rarely match CAD perfectly — and SnapCam solves that.

SnapCam Advantages:

- 3D point-cloud seam finding with thousands of data points

- Automatic joint detection for T-joints, lap joints, etc.

- Real-time offset correction

- Increased arc-on time + higher deposition rates

- Up to 30% faster vs. laser sensors

- Robust design for harsh welding environments

LayoutMaster (Optional) – Augmented Reality Fitting

The LayoutMaster uses CAD data and color laser projection to guide the operator during fitting.

What Operators See:

- Part contours (2D & 3D)

- Weld symbols and weld locations

- Part descriptions

- Color-coded layers for fast identification

This eliminates tape measures, reduces errors, and makes any operator your best fitter in minutes.

Finance

Why Finance Your Equipment with Tech Financial?

Financing your equipment through Tech Financial unlocks a world of possibilities for your business. With flexible payment plans, tailored solutions, and quick credit approvals, you can preserve working capital while accessing the latest technology to stay competitive. Enjoy potential tax advantages, affordable rates, and a seamless application process designed to get you the equipment you need without delays. Tech Financial’s expertise and customer-focused approach make investing in your business’s future easier and more cost-effective than ever.

Ready to get started? Apply today and take the next step toward smarter financing!