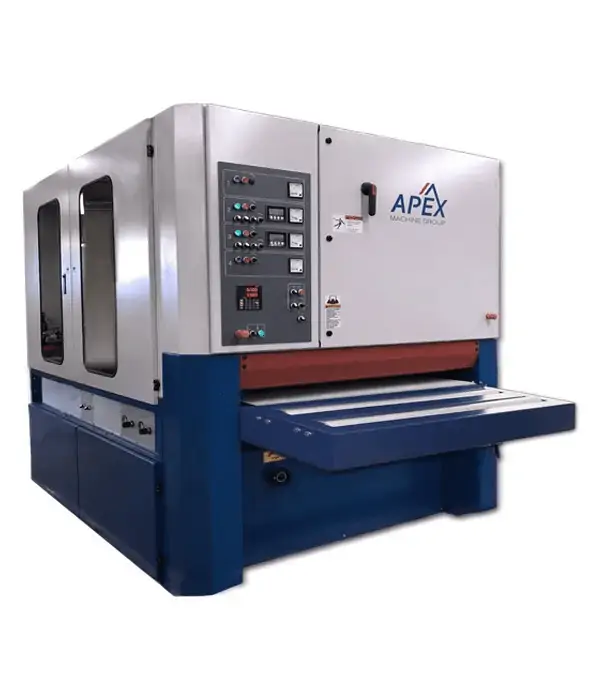

APEX TOP AND BOTTOM DEBURRING MACHINE

Deburring, Edge Radius, Laser Oxide Removal, Surface Prep

The Apex TB-1600 Top/Bottom machine processes both the top and bottom surfaces of parts in a single pass with 100% uniformity. Every square inch of every part is processed exactly the same over 100% of the machine width. It is equipped with oscillating and rotating sanding discs designed for effective deburring, edge radius, laser oxide removal, weld-point clean-up and surface preparation for powder coating, painting and e-coating. The machine has two single row disc stations on top, with each top disc station consisting of twelve 150 mm (6″) discs. There are two single row disc stations on the bottom, with each bottom disc station consisting of twelve 150 mm (6″) discs for processing the bottom of parts.

Videos APEX TOP AND BOTTOM DEBURRING MACHINE

APEX TOP AND BOTTOM DEBURRING MACHINE

Description

Description

Deburring, Edge Radius, Laser Oxide Removal, Surface Prep

The Apex TB-1600 Top/Bottom machine processes both the top and bottom surfaces of parts in a single pass with 100% uniformity. Every square inch of every part is processed exactly the same over 100% of the machine width. It is equipped with oscillating and rotating sanding discs designed for effective deburring, edge radius, laser oxide removal, weld-point clean-up and surface preparation for powder coating, painting and e-coating. The machine has two single row disc stations on top, with each top disc station consisting of twelve 150 mm (6″) discs. There are two single row disc stations on the bottom, with each bottom disc station consisting of twelve 150 mm (6″) discs for processing the bottom of parts.

Machine Features

Machine Features

MACHINE FEATURES

- Machines built in widths from 40″ to 100″, depending on maximum width of parts to be processed

- Separate variable speed adjustment for disc rpm and oscillation

- Convenient pull-out of disc station on left and right for speedy changing of abrasive sanding strips

- Rotation of discs is reversible

- Features constant pass-line (900 mm)

- Pressure rollers for holding parts down

- LED lights mounted inside the machine for clear visibility

- Dual infeed and outfeed support pinch rollers to ensure parts feed through machine properly

- Heavy duty chain-driven feed rollers

Machine Specifications

Machine Specifications

MACHINE SPECIFICATIONS

SPECIFICATION DESCRIPTION

Belt Width 40″ to 100″

Thickness of Workpiece Minimum 0mm to Maximum 80mm

Motor for Disc Station Rotation 2.2kW 100-700 rpm

Motor for Disc Station Oscillation 0.37kW 40 rpm, oscillation movement 100mm

Number of Discs (bottom) 12 discs x 2 rows (top) and 12 discs x 2

Diameter of Standing Discs 150 mm (6″); 250 mm (10″) available

Feed Speed 3-25 feet per minute

Dust Collection Ports Three (3) 150mm ports per disc station

Dust Collection Requirements Minimum 6,500 CFM

Machine Weight 6,050 lbs.

Machine Dimensions 84″ L x 90″ W x 80″ H

Machine Videos

Machine Videos

MACHINE VIDEOS

TB-1600 64″ Wide Top/Bottom Brush Machine

Deburring, edge radius, and surface scuffing on an Apex TB-1600

TB-1600 Top/Bottom Metal Brush Machine

Deburring action from every angle and every direction for 100% edge uniformity on both top and bottom side of parts in a single pass. Perfect surface for mechanical bond for paint adhesion.

Deburring and edge radiusing on Apex TB-1600

Finance

Why Finance Your Equipment with Tech Financial?

Financing your equipment through Tech Financial unlocks a world of possibilities for your business. With flexible payment plans, tailored solutions, and quick credit approvals, you can preserve working capital while accessing the latest technology to stay competitive. Enjoy potential tax advantages, affordable rates, and a seamless application process designed to get you the equipment you need without delays. Tech Financial’s expertise and customer-focused approach make investing in your business’s future easier and more cost-effective than ever.

Ready to get started? Apply today and take the next step toward smarter financing!