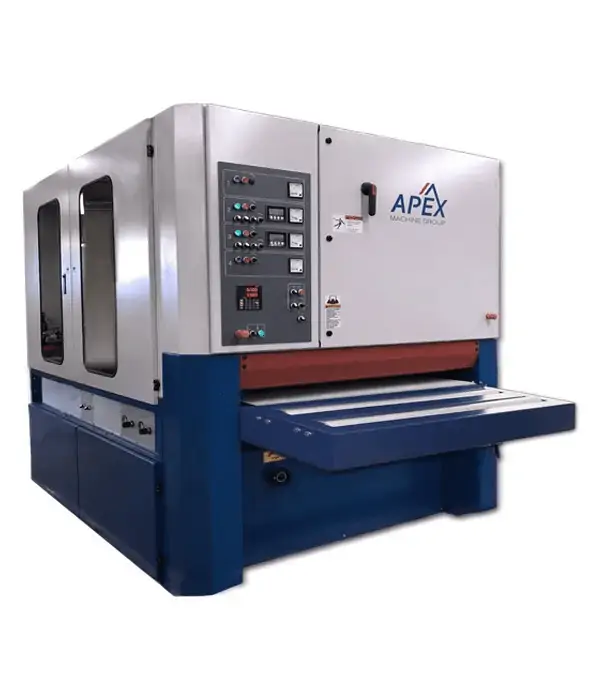

APEX 2000 SERIES WET METAL MACHINES

Deburring, Grinding, Edge Radiusing

The 2000-Series of machines are built with heavier production requirements in mind. They are designed to run multiple shifts per day and handle such applications as deburring, slag grinding, calibrating/dimensioning, edge radiusing, paint/surface preparation, finishing/polishing or a combination of these applications. This series of machine can be built in both top and bottom configurations.

Videos APEX 2000 SERIES WET METAL MACHINES

APEX 2000 SERIES WET METAL MACHINES

Description

Description

Deburring, Grinding, Edge Radiusing

The 2000-Series of machines are built with heavier production requirements in mind. They are designed to run multiple shifts per day and handle such applications as deburring, slag grinding, calibrating/dimensioning, edge radiusing, paint/surface preparation, finishing/polishing or a combination of these applications. This series of machine can be built in both top and bottom configurations.

Machine Features

Machine Features

MACHINE FEATURES

- Machines built in widths from 19″ to 52″ and multiple head frames

- Dual infeed and outfeed pinch rolls to ensure parts feed through machine properly

- One- to four-head configurations with drum, brush and disc heads or combination drum/brush/disc heads

- Spray headers on both sides of sanding area to keep parts cool and belts clean during operation

- Individual cam adjustment down to .001″ per head for accurate finishing

- Paper media filtration system with automatic paper advance for ease of operation

- Air-loaded cylinder for automated belt tensioning

- Automatic abrasive belt tracking to ensure proper belt alignment during operation.

Machine Specifications

Machine Specifications

MACHINE SPECIFICATIONS

SPECIFICATION DESCRIPTION

Belt Width 19’ to 52’

Motor Size 7.5 HP to 50 HP

Number of Heads 1 to 4

Types of Heads Drum, Scotch-Brite, Brush and Disc

Available

Drum Size 100 mm to 280 mm

Machine Top-Only

Configuration

Feed Motor 1 HP to 3 HP

Machine Videos

Machine Videos

MACHINE VIDEOS

This video demonstrates polishing stainless steel parts using an Apex Machine Group Model 2037MW-DDDD. This 4-head machine is equipped with four separate abrasive belt heads that allow for a #4 up to a mirror finish on stainless steel parts in a single pass.

This video shows a stainless steel part with drilled holes being processed on a wet metalworking machine. The Apex Model 2037MW-DSD is a 3-head abrasive belt / rotating disc / abrasive belt deburring and finishing machine. It will remove the burrs and give edge radius if desired on aluminum, stainless steel, copper, titanium, carbon steel and other ferrous and non-ferrous metal materials.

Finance

Why Finance Your Equipment with Tech Financial?

Financing your equipment through Tech Financial unlocks a world of possibilities for your business. With flexible payment plans, tailored solutions, and quick credit approvals, you can preserve working capital while accessing the latest technology to stay competitive. Enjoy potential tax advantages, affordable rates, and a seamless application process designed to get you the equipment you need without delays. Tech Financial’s expertise and customer-focused approach make investing in your business’s future easier and more cost-effective than ever.

Ready to get started? Apply today and take the next step toward smarter financing!