As a Regional Sales Executive at Mac-Tech, I’ve had the privilege of working closely with numerous fabricators across the Midwest. One thing remains clear: staying competitive means staying innovative. Our fabricators have embraced hybrid workflows, blending lasers, brakes, and tooling to push the boundaries of efficiency and precision. Let’s dive into how these strategies are transforming their operations.

Comparing Laser Power: Insights from Midwest Fabricators

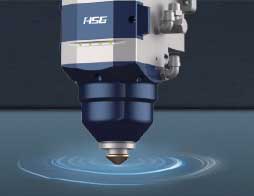

One common challenge I encounter is selecting the right laser power for specific applications. Many fabricators grapple with finding the balance between cutting speed and energy consumption. By choosing the right laser, such as the HSG or Rytech models, they can optimize power usage without compromising on speed. This not only reduces operating costs but also enhances throughput, allowing businesses to meet tight deadlines with ease.

Minimizing Downtime: Strategies for Faster Setups

Downtime is the silent profit killer. Fabricators often struggle with lengthy setup times, particularly when switching between different jobs. Integrating automation systems like Prodevco can drastically cut setup times. With automated tool changers and advanced CNC controls, fabricators reduce manual intervention, leading to quicker transitions and more consistent production runs.

Maximizing ROI: The Impact of Tooling and Controls

Investing in quality tooling and controls is paramount for maximizing ROI. Many fabricators have seen significant returns by incorporating Wilson Tool’s advanced solutions. These tools enhance precision and reduce material waste, translating to direct savings. Additionally, modern CNC controls offer unparalleled accuracy, ensuring that every cut and bend is perfect the first time, every time.

HURCO CNC CONTROLS

AUTOMEC CNC BACKGAUGE CONTROL SYSTEMS

Workflow Integration: Achieving Smoother Operations

Seamless workflow integration is key to smoother operations. By combining lasers, brakes, and tooling in a cohesive system, fabricators achieve a streamlined production line. Ermaksan’s integrated systems allow for real-time data sharing and process adjustments, minimizing errors and ensuring that every component fits perfectly within the larger production puzzle.

Future Investments: Where Smart Fabricators Are Heading Next

Looking ahead, smart fabricators are focusing on future-proofing their operations. Investments in IoT-enabled machines and advanced software solutions are on the rise. These technologies offer predictive maintenance and real-time analytics, giving fabricators the edge in proactive decision-making. Staying ahead means embracing these innovations to maintain a competitive edge in an ever-evolving industry landscape.

FAQ Section

What wattage should I choose for my laser cutter?

It depends on your material and thickness requirements. Higher wattages cut thicker materials faster, but also consume more energy.

How can I integrate automation into my current setup?

Start by assessing your current workflow and identifying bottlenecks. Incremental integration, like adding automated tool changers, can be a good first step.

What maintenance is required for these machines?

Regular cleaning and calibration are essential. Follow the manufacturer’s guidelines and consider a service contract for comprehensive maintenance.

Is training available for new software and machines?

Yes, most manufacturers provide training sessions. At Mac-Tech, we offer tailored training programs to ensure your team is up to speed.

What is the typical lead time for new equipment?

Lead times vary based on the machine and customization required. Generally, you should expect a few months from order to delivery.

If you’re ready to explore how hybrid workflows can transform your operation, I’m here to help. Feel free to reach out for a walkthrough or demo. Together, we can elevate your fabrication capabilities to new heights.

Get Weekly Mac-Tech News & Updates